Transparent conductive electrode with concave structure and preparation method thereof

A transparent conductive electrode, recessed structure technology, applied in the manufacture of conductive/antistatic filament, conductive layer on insulating carrier, cable/conductor manufacture, etc., can solve the limitation of photoelectric performance, contact resistance and surface roughness of transparent electrodes It can achieve good industrialization prospects, reduce surface roughness, improve weather resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] A transparent conductive electrode with a concave structure, which is prepared by the following steps:

[0072] First add 3mL of water and 2mL of ethanol into a 25mL beaker, add 0.5g of silver nitrate, and completely dissolve the silver nitrate under magnetic stirring. Place the silver nitrate solution in an ice-water bath, add 3 mL of isopropylamine under magnetic stirring, stir for 45 minutes, add 0.3 mL of ethylene glycol, continue stirring for 1 hour, and then filter with filter paper.

[0073]Subsequently, 0.3 g of polyethylene oxide, 0.5 g of polyvinyl pyrrolidone and 0.01 g of polyethylene glycol were added, and stirred at room temperature for 24 hours to obtain a spinning solution.

[0074] The transparent polyimide film is used as the receiving substrate, and it is wrapped on the surface of the conductive drum, and the positive and negative electrodes of the high-voltage DC power supply are respectively connected to the spinning nozzle and the drum. A 1.0 mm s...

Embodiment 2

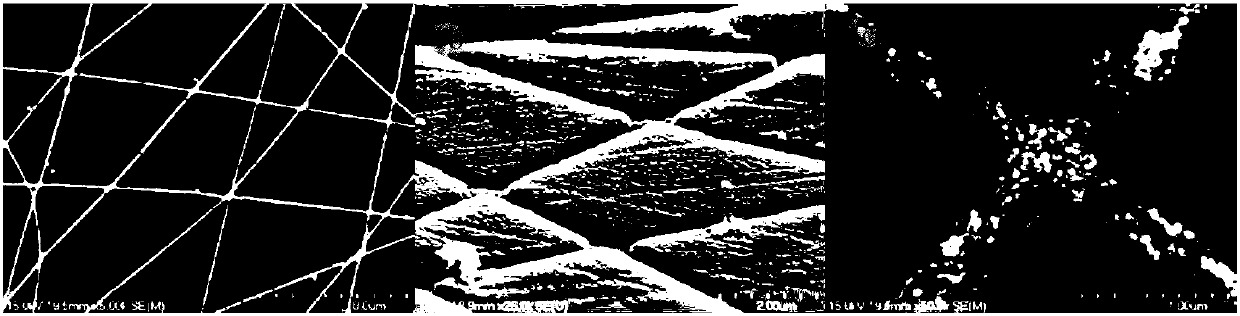

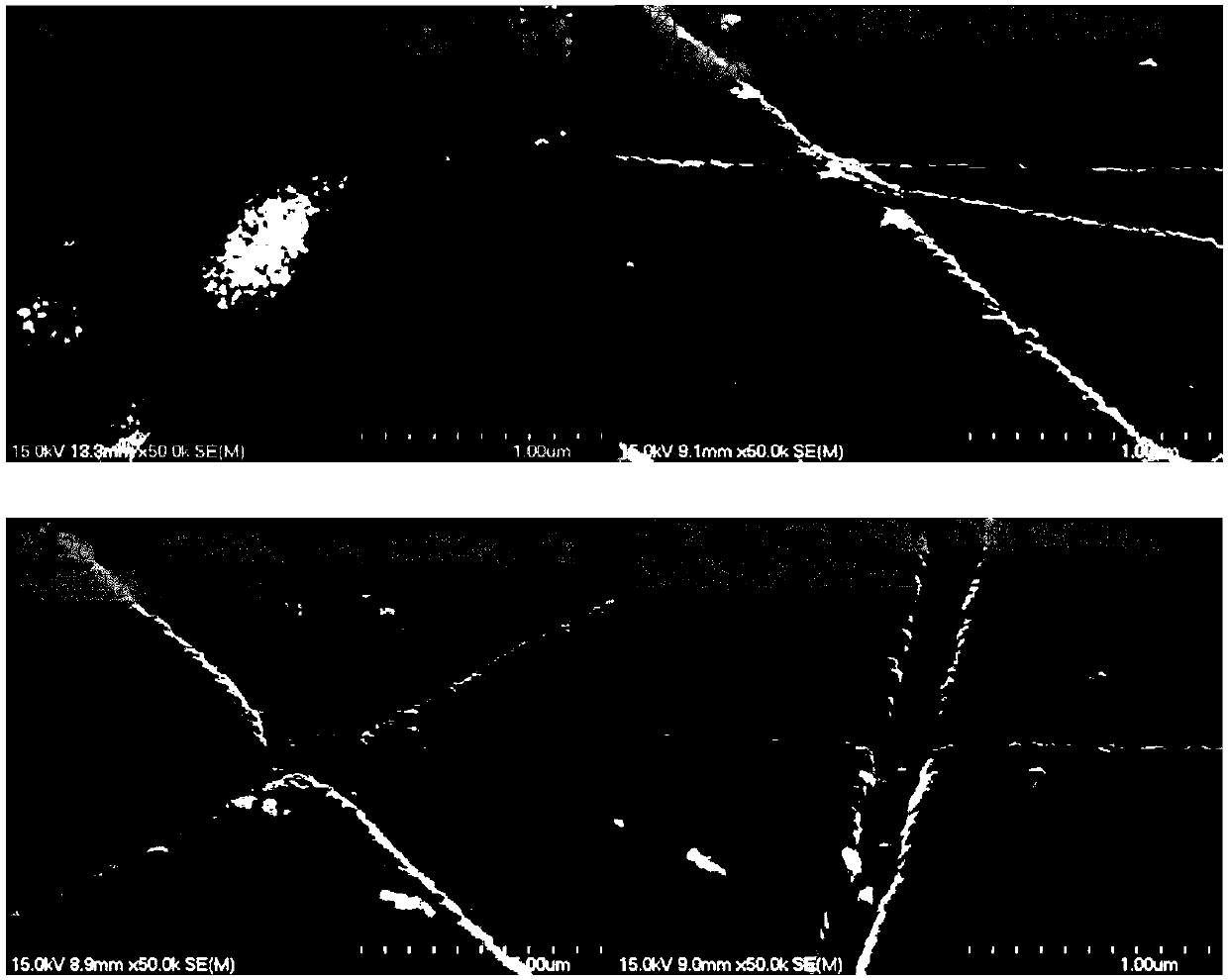

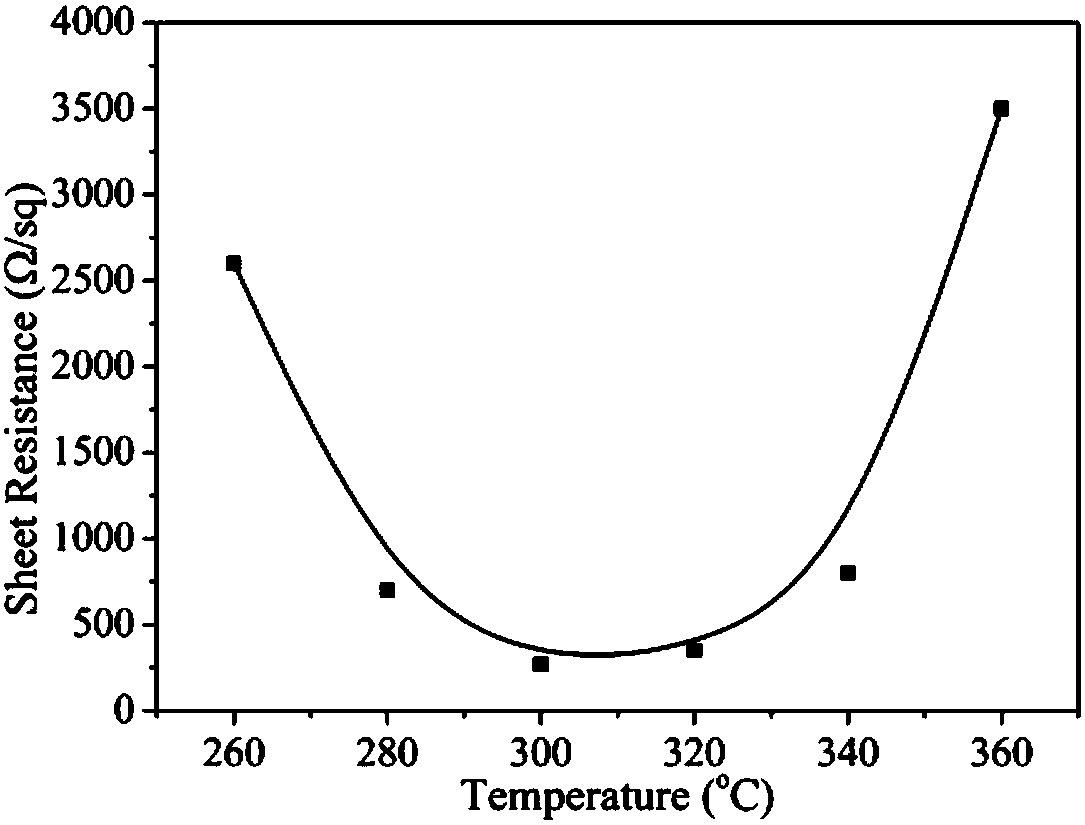

[0077] On the basis of Example 1, the difference in this example is that the polyimide film whose surface is covered with spun fibers is placed in a muffle furnace, and reacted at 240°C, 280°C and 320°C for 60 minutes respectively to obtain Conductive nanofiber films. The SEM results of the variation of the depth of the depression with the heating temperature are shown in figure 2 As shown, among them, the fiber membrane obtained by 240℃ treatment is non-conductive and has no intercalation; the fiber membrane obtained by 280℃ treatment has a conductivity of 700Ω / sq and no intercalation; The conductive fiber film obtained in Example 1 at 300°C conducts electricity at 270 Ω / sq, and the embedding depth is about 100 nm. The change diagram of the square resistance with the depth of the depression can be obtained, and the results are shown in image 3 It can be seen that when the temperature is lower than 280°C, the polymer is not completely decomposed, the reduction of silver nit...

Embodiment 3

[0079] On the basis of Example 1, a transparent conductive electrode with a concave structure composed of silver conductive nanofibers was used as the electroplating cathode, and a nickel plate was used as the electroplating anode, and was electroplated at a constant voltage in a nickel-containing electroplating solution, and the distance between the plates was adjusted to 3 cm. Voltage 5V, electroplating time 5min. Among them, the formulation of the electroplating solution is as follows: nickel sulfate 350g / L, nickel chloride 30g / L, boric acid 30g / L. The obtained silver conductive nanofiber composition has a concave structure, and the SEM image of the nickel-plated transparent conductive electrode is shown in Figure 4 It can be seen from Comparative Example 1 that after electroplating nickel on the silver fiber transparent conductive electrode with a concave structure, the surface of the fiber is obviously covered with a layer of metal, and the concave structure is filled. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth of depression | aaaaa | aaaaa |

| Sheet resistance | aaaaa | aaaaa |

| Depth of depression | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com