Magnetorheological elastomer grinding wheel and preparation method thereof

A magneto-rheological elastomer and grinding wheel technology, applied in the field of grinding wheels, can solve the problems of difficult control of the processing process, low processing efficiency, long cycle, etc., and achieve the effect of reducing surface damage of the workpiece, reducing sub-surface damage, and improving self-adaptive ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

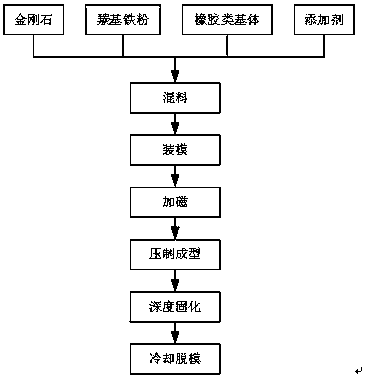

[0047] The present invention also provides a preparation method of a magnetorheological elastomer grinding wheel, comprising the following steps:

[0048] 1. Mixing, use mechanical stirring and mixing or mechanical vibration stirring and mixing to mix the weighed ingredients evenly for later use;

[0049] 2. Install the mold, evenly coat the release agent on the wall of the mold cavity, and evenly pack the mixture in step 1 into the mold, which is a non-magnetic material;

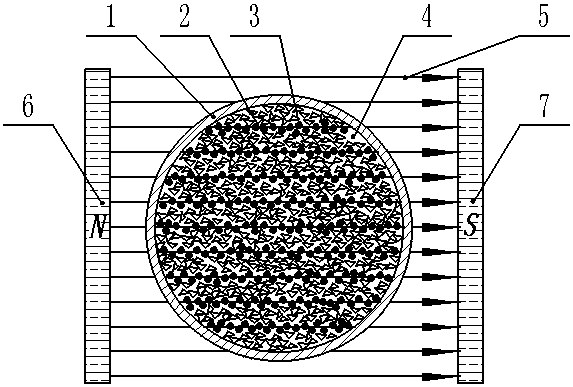

[0050]3. Add magnetism, apply a magnetic field around the mold and let it stand for a while, so that the magnetic particles are redistributed under the force of the magnetic field;

[0051] 4. Press molding, apply a certain amount of pressure on the mold, and press the grinding wheel into shape;

[0052] 5. For deep curing, place the formed grinding wheel and mold together at room temperature or in a heating device to heat and keep warm for a period of time;

[0053] 6. Cooling and demoulding, after the g...

Embodiment 1

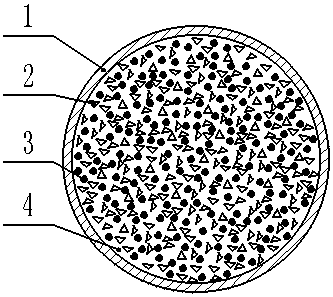

[0062] Silicone Rubber Based Magnetorheological Elastomer Grinding Wheel

[0063] Raw material preparation: 40% diamond abrasive grains, 30% carbonyl iron powder, 23% two-component silicone rubber, 5% dimethyl silicone oil, and 2% polysiloxane.

[0064] The preparation method is as follows:

[0065] 1) Weigh the raw materials of each component according to the mass ratio, and dry the silicone rubber and dimethyl silicone oil in a vacuum drying oven at 80°C for 1 hour to remove water;

[0066] 2) Mix silicone rubber and dimethyl silicone oil evenly as component A, mix abrasive grains and iron powder evenly as component B, then mix components A and B and add polysiloxane to stir evenly for later use. Stirring device to mix raw materials;

[0067] 3) Pour the mixture into the mold, and let the ferromagnetic particles form an ordered chain or columnar structure under the condition of a magnetic field strength of 750mT;

[0068] 4) Put the mold under the press and apply a pressu...

Embodiment 2

[0071] Natural rubber-based magnetorheological elastomer grinding wheel

[0072] Raw material preparation: 40% diamond abrasive grains, 30% carbonyl iron powder, 23% ammonium gum, 4% zinc oxide, 0.7% stearic acid, 0.3% accelerator CZ, and 2% sulfur.

[0073] The preparation method is as follows:

[0074] 1) Weigh the raw materials of each component according to the mass ratio, and dry the ammonium gum in a vacuum drying oven at 60°C for 1 hour to remove water;

[0075] 2) Mix additives including zinc oxide, stearic acid, accelerator CZ and sulfur as component A, mix abrasive grains and iron powder as component B, first add component B to the ammonium gum Mix evenly to obtain a mixture, then add component A to the mixture and mix evenly for later use, and use a mechanical stirring device to mix the raw materials;

[0076] 3) Put the mixture into the mold, provide 750mT magnetic field strength conditions and 80°C temperature conditions, so that the ferromagnetic particles form...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com