Catalytic depolymerization of sugarcane bagasse lignin to prepare aromatic oxygenates

A technology for catalytic depolymerization and lignin, which is applied in the field of efficient catalytic conversion and resource utilization of bagasse lignin, can solve problems such as low waste utilization efficiency, and achieve the effects of avoiding resource waste and high catalytic activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

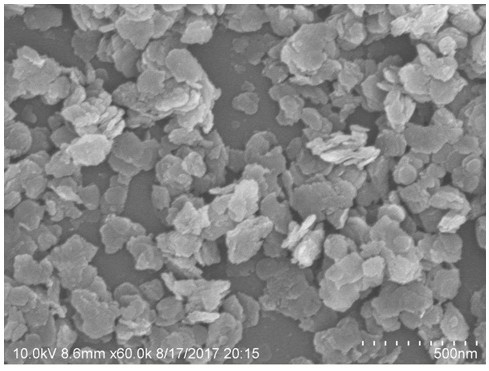

Image

Examples

Embodiment 1

[0030] The method for producing aromatic group oxygenates by catalytic depolymerization of sugarcane bagasse lignin:

[0031] Weigh 1.164g Ni(NO 3 ) 2 •6H 2 O, 1.536g Mg(NO 3 ) 2 •6H 2 O, 1.01g Fe(NO 3 ) 3 •9H 2 O was successively dissolved in 50 mL of distilled water, and then 5 mL of absolute ethanol solution was added, and stirred continuously for 30 minutes with a magnetic stirrer. Titrate the above solution with 2mol / L NaOH solution, when the pH value is 11, continue to stir the solution after the titration is completed, so that the solution is fully stirred evenly. After the titration and stirring, the solution was ultrasonically treated in an ultrasonic disperser for 5 minutes. After taking it out, the solution was put into the reactor and reacted for 24 hours at 160°C. After the reaction, the lining of the reactor was taken out, and the separated lower sediment Wash and centrifuge. Centrifuge for 3 minutes each time, the speed of centrifugation is 12000 min / r...

Embodiment 2

[0035] The method for producing aromatic group oxygenates by catalytic depolymerization of sugarcane bagasse lignin:

[0036] Weigh 1.164g Ni(NO 3 ) 2 •6H 2 O, 1.536g Mg(NO 3 ) 2 •6H 2 O, 1.01g Fe(NO 3 ) 3 •9H 2 O was successively dissolved in 50 mL of distilled water, and then 5 mL of ethylene glycol solution was added, and stirred continuously for 30 minutes with a magnetic stirrer. Titrate the above solution with 2 mol / L NaOH solution, when the pH value is 10.5, continue to stir the solution after the titration is completed, so that the solution is fully stirred evenly. After the titration and stirring, the solution was ultrasonically treated in an ultrasonic disperser for 5 minutes. After taking it out, the solution was put into the reactor and reacted for 24 hours at 180°C. After the reaction, the lining of the reactor was taken out, and the separated lower sediment Wash and centrifuge. Centrifuge for 3 minutes each time, the speed of centrifugation is 12000 min / r...

Embodiment 3

[0040] The method for producing aromatic group oxygenates by catalytic depolymerization of sugarcane bagasse lignin:

[0041] Weigh 1.745g Ni(NO 3 ) 2 •6H 2 O, 1.536g Mg(NO 3 ) 2 •6H 2 O, 1.212g Fe(NO 3 ) 3 •9H 2 O was successively dissolved in 50 mL of distilled water, then 5 mL of starch solution was added, and stirred continuously for 30 minutes with a magnetic stirrer. Titrate the above solution with 2 mol / L NaOH solution, when the pH value is 11, continue to stir the solution after the titration is completed, so that the solution is fully stirred evenly. After the titration and stirring, the solution was ultrasonically treated in an ultrasonic disperser for 5 minutes. After taking it out, put the solution into the reactor and react at 180°C for 18 hours. After the reaction, the lining of the reactor was taken out, and the separated lower sediment Wash and centrifuge. Centrifuge for 3 minutes each time, the speed of centrifugation is 12000 min / rev, wash away the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com