Electroluminescence polymer as well as polymerization monomer and preparation method and application thereof

A technology for polymerizing monomers and electroluminescence, applied in the field of polymerizing monomers and electroluminescent polymers, can solve the problems of high price of OLED products, low material utilization rate, expensive equipment and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0060] One, the preparation of polymerized monomer (C1)

[0061] (1) Preparation of ethylthiophene-3-carboxylate

[0062] In a 500mL three-necked flask, thiophene-3-carboxylic acid (12.8g, 0.1mol) was dissolved in 200mL of methanol, and 20mL of concentrated sulfuric acid was added dropwise to the reaction solution, and after stirring at room temperature for 12 hours, the reaction was stopped, and the reaction was quenched with water , extracted with dichloromethane and dried with anhydrous magnesium sulfate, the solution was concentrated to obtain a yellow liquid, which was purified by silica gel column chromatography, and the mixed solvent of petroleum ether / dichloromethane (5 / 1, v / v) was eluting agent, yield 73%. 1 H NMR, 13 CNMR, MS and elemental analysis results show that the obtained compound is the target product, and the chemical reaction equation of the preparation process is as follows:

[0063]

[0064] (2) Preparation of ethyl 2-(tributyltin)thiophene-3-carbox...

Embodiment example 1

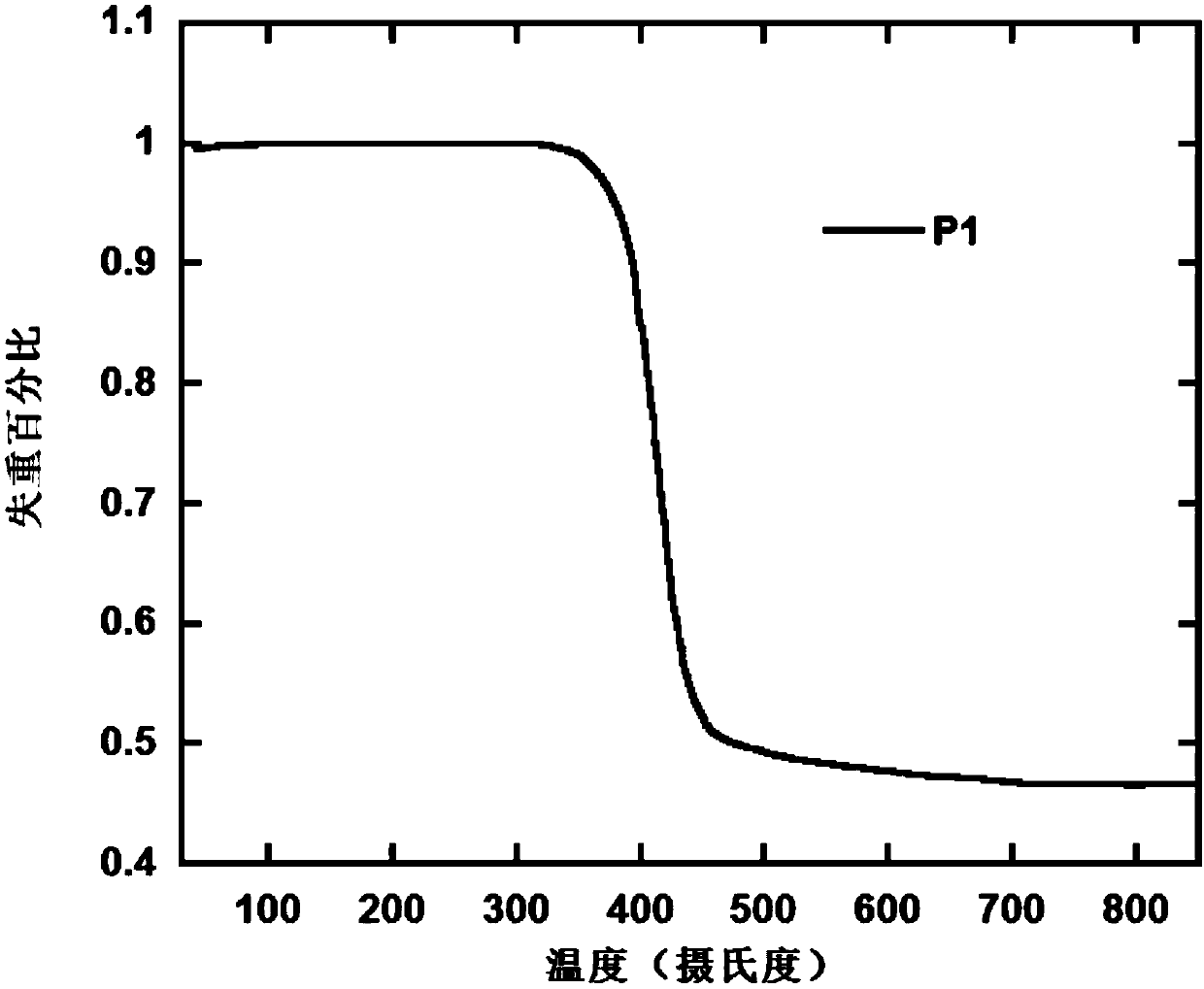

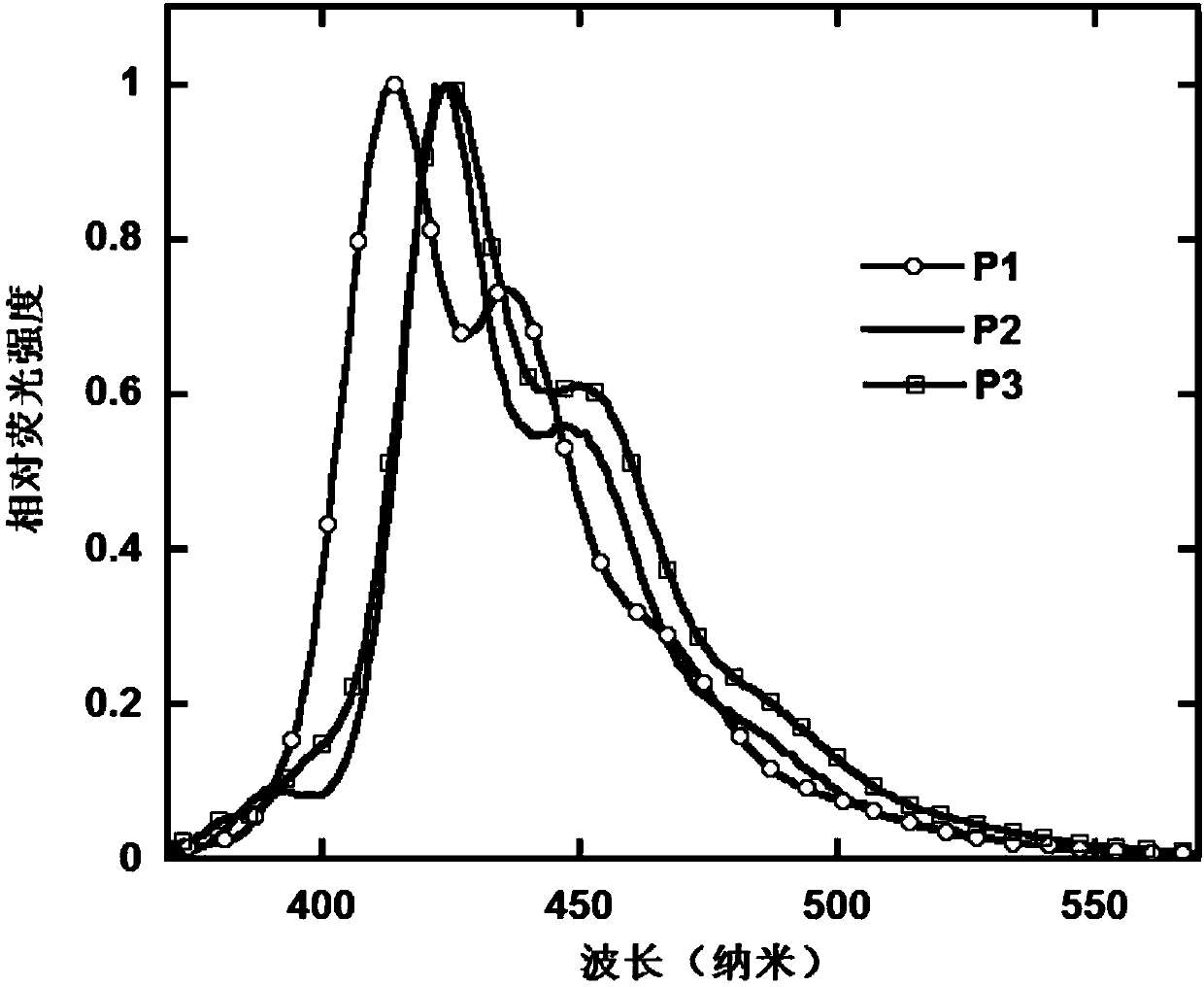

[0121] Example 1: Synthesis of Polymer P1

[0122] Under argon atmosphere, 2,7-bis(4,4,5,5-tetramethyl-1,3,2-dioxaborolane-diyl)-9,9-dioctylfluorene ( 321mg, 0.50mmol), 2,7-dibromo-9,9-dioctylfluorene (246.8mg, 0.45mmol) and polymerized monomer C1 (49mg, 0.05mmol) were added to a 50mL two-necked bottle, and then 12mL of refined toluene was added , then add palladium acetate (2.80 mg, 12.45 μmol) and tricyclohexylphosphine (6.98 mg, 24.90 μmol), then add 3 mL of organic base, heat up to 80 ° C, and react for 24 hours; then add 20 mg of phenylboronic acid for capping, 12 After 1 hour, use 0.3mL bromobenzene to carry out capping again; After continuing to react for 12 hours, stop the reaction, wait until the temperature drops to room temperature, add the product dropwise in 300mL methanol for precipitation, filter, then dissolve the crude product in 20mL of toluene In the process, 200-300 mesh silica gel is used as the stationary phase, and toluene is used as the eluent for colu...

Embodiment example 2

[0126] Example 2: Synthesis of Polymer P2

[0127] Under argon atmosphere, 2,7-bis(4,4,5,5-tetramethyl-1,3,2-dioxaborolane-diyl)-9,9-dioctylfluorene ( 321mg, 0.50mmol), 2,7-dibromo-9,9-dioctylfluorene (219.4mg, 0.40mmol) and polymer monomer C1 (98mg, 0.10mmol) were added to a 50mL two-necked bottle, and then 12mL refined toluene was added , then add palladium acetate (2.80 mg, 12.45 μmol) and tricyclohexylphosphine (6.98 mg, 24.90 μmol), then add 3 mL of organic base, heat up to 80 ° C, and react for 24 hours; then add 20 mg of phenylboronic acid for capping, 12 After 1 hour, use 0.3mL bromobenzene to carry out capping again; After continuing to react for 12 hours, stop the reaction, wait until the temperature drops to room temperature, add the product dropwise in 300mL methanol for precipitation, filter, then dissolve the crude product in 20mL of toluene In the process, 200-300 mesh silica gel is used as the stationary phase, and toluene is used as the eluent for column chro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com