A kind of immobilized enzyme oil spill degradation agent

A technology for immobilizing enzymes and degrading agents, applied in the direction of immobilizing enzymes, immobilizing enzymes on or in inorganic carriers, enzymes, etc., can solve problems such as hindering plant photosynthesis under the ocean, water hypoxia, stimulating red tides, etc. Activity and degradation efficiency, increased contact area, and the effect of a wide working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

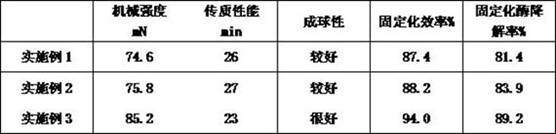

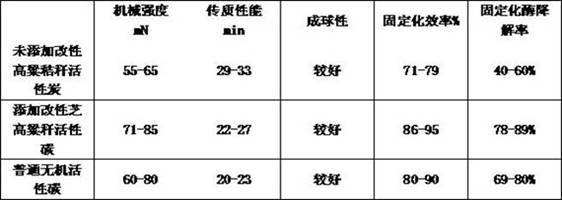

Embodiment 1

[0018] An immobilized enzyme oil spill degradation agent, the mass percentage concentration of sorghum straw activated carbon in the immobilized enzyme oil spill degradation agent is 1.5-2.2%, the mass percentage concentration of sodium alginate is 6.8-7.9%, and the concentration of the compound enzyme is 6×10 6 -8×10 6 cell / g, the salinity of the immobilized enzyme oil spill degradation agent is 5-55‰, the temperature is 10-30°C, the pH is 6.5-9.0, and the degradation rate of petroleum hydrocarbons can reach 70-90%. Compared with free enzyme solution, its degradation rate is increased by 35%-50%, and it has strong environmental tolerance and mechanical properties. Sorghum straw activated carbon greatly improves the mass transfer of immobilized enzyme oil spill degradation agent. The contact area between the enzyme liquid and petroleum is increased, which greatly improves the activity and degradation efficiency of microorganisms.

Embodiment 2

[0020] The preparation method of immobilized enzyme oil spill degradation agent comprises the following steps:

[0021] 1) Enzyme liquid preparation: Suction filter the chlorella liquid after 7 days of cultivation and in the logarithmic growth phase, use a filter membrane of 0.55 μm, remove the filter membrane containing chlorella, freeze it with liquid nitrogen, and then add 2.8 times of PBS buffer solution, the pH of PBS buffer solution is 6.8, and the concentration is 0.35mol / L; grind at 0°C, pour the grinding solution into a centrifuge tube and centrifuge at 0°C, 8500r / min for 30 minutes, take out the upper The clear liquid is the enzyme liquid, which is stored at 0°C; the chlorella in the logarithmic growth phase is filtered, ground, and centrifuged to obtain the enzyme liquid. The preparation process of the enzyme liquid is simple and easy, and extraction at low temperature will not destroy Enzyme activity;

[0022] Phosphoric acid activation: Weigh the dried sorghum st...

Embodiment 3

[0027] An immobilized enzyme oil spill degradation agent, the mass percentage concentration of sorghum straw activated carbon in the immobilized enzyme oil spill degradation agent is 1.5-2.2%, the mass percentage concentration of sodium alginate is 6.8-7.9%, and the concentration of the compound enzyme is 6×10 6 -8×10 6cell / g, the salinity of the immobilized enzyme oil spill degradation agent is 5-55‰, the temperature is 10-30°C, the pH is 6.5-9.0, and the degradation rate of petroleum hydrocarbons can reach 70-90%. Compared with free enzyme solution, its degradation rate is increased by 35%-50%, and it has strong environmental tolerance and mechanical properties. Sorghum straw activated carbon greatly improves the mass transfer of immobilized enzyme oil spill degradation agent. The contact area between the enzyme liquid and petroleum is increased, which greatly improves the activity and degradation efficiency of microorganisms.

[0028] The preparation method of the immobil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com