Thermal barrier coating and preparation method thereof

A thermal barrier coating, thermal barrier technology, applied in the direction of coating, metal material coating process, melt spraying, etc., can solve the problems of peeling, coating cracking, coating life reduction, etc., to eliminate holes, refine grains, the effect of reducing thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

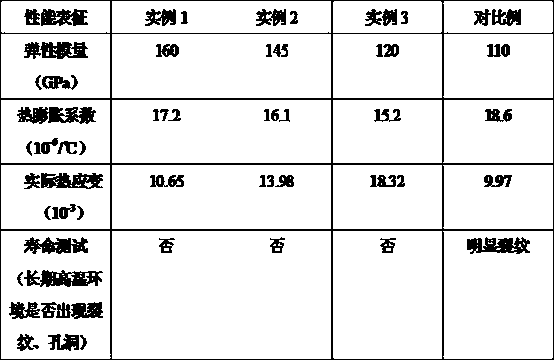

Examples

example 1

[0023] Take samarium nitrate, gadolinium nitrate, ytterbium nitrate, cerium nitrate, and zirconium nitrate, mix them in deionized water at a molar ratio of 5:3:2:0.1:9.0, stir at 300r / min for 20min, then add ammonia water dropwise at 1mL / min to No precipitation occurs, filter the filter residue after standing for 1 hour, wash the filter residue with deionized water until the washing liquid is neutral, and obtain a precursor, place the precursor in a drying oven, dry at 105°C to constant weight, and then transfer to In a muffle furnace, calcined at 1000°C for 1 hour, cooled to room temperature, put it into a grinder and ground it for 1 hour to obtain thermal barrier ceramic powder, cut nickel-based superalloy K417 into a cylinder of Φ20mm×5mm, and ultrasonicated with kerosene and alcohol Clean twice, then sandblast the surface with corundum grit, control the average particle size of the grit to 200μm, and the blasting pressure to 1.5×10 5 Pa, the sandblasting angle is 45°, the ...

example 2

[0025] Take samarium nitrate, gadolinium nitrate, ytterbium nitrate, cerium nitrate, and zirconium nitrate, mix them in deionized water at a molar ratio of 5:3:2:0.5:9.5, stir at 350r / min for 25min, then add ammonia water dropwise at 1mL / min to No precipitation occurs, filter residue after standing for 1 hour, wash the filter residue with deionized water until the washing liquid is neutral, and obtain a precursor, place the precursor in a drying oven, dry at 107°C to constant weight, and then transfer to In a muffle furnace, calcined at 1100°C for 2 hours, cooled to room temperature, put it into a grinder and ground it for 1 hour to obtain thermal barrier ceramic powder, cut nickel-based superalloy K417 into a cylinder of Φ20mm×5mm, and ultrasonicated with kerosene and alcohol Clean twice, and then sandblast the surface with corundum grit, control the average particle size of the grit to 210μm, and the blasting pressure to 1.5×10 5 Pa, the sandblasting angle is 52°, the sandblas...

example 3

[0027] Take samarium nitrate, gadolinium nitrate, ytterbium nitrate, cerium nitrate, zirconium nitrate, mix them in deionized water at a molar ratio of 5:3:2:1:9.9, stir at 400r / min for 30min, then add ammonia water dropwise at 2mL / min to No precipitation occurs, filter the filter residue after standing for 2 hours, wash the filter residue with deionized water until the washing liquid is neutral, and obtain a precursor, place the precursor in a drying oven, dry at 110°C to constant weight, and then transfer to In a muffle furnace, calcined at 1200°C for 3 hours, cooled to room temperature, put it into a grinder and ground it for 2 hours to obtain thermal barrier ceramic powder, cut nickel-based superalloy K417 into a cylinder of Φ20mm×5mm, and ultrasonicated with kerosene and alcohol After cleaning for 3 times, the surface is sandblasted with corundum grit, the average particle size of the grit is controlled to be 220 μm, and the blasting pressure is 1.5×10 5 Pa, the sandblast...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com