Hollow fiber membrane contactor and application thereof

A technology of fiber membrane contactor and membrane contactor, applied in the direction of membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve problems such as difficult operation, uneven distribution of shell side, low filling rate of membrane filaments, etc., to achieve Structural optimization, enhanced mass transfer effect, effect of maintaining filling rate and contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

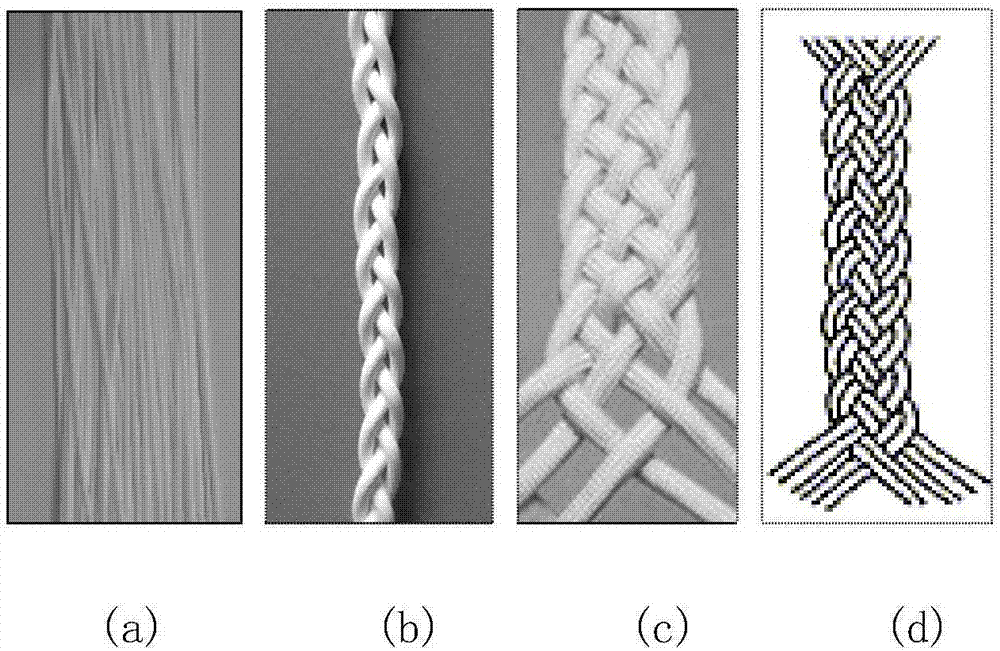

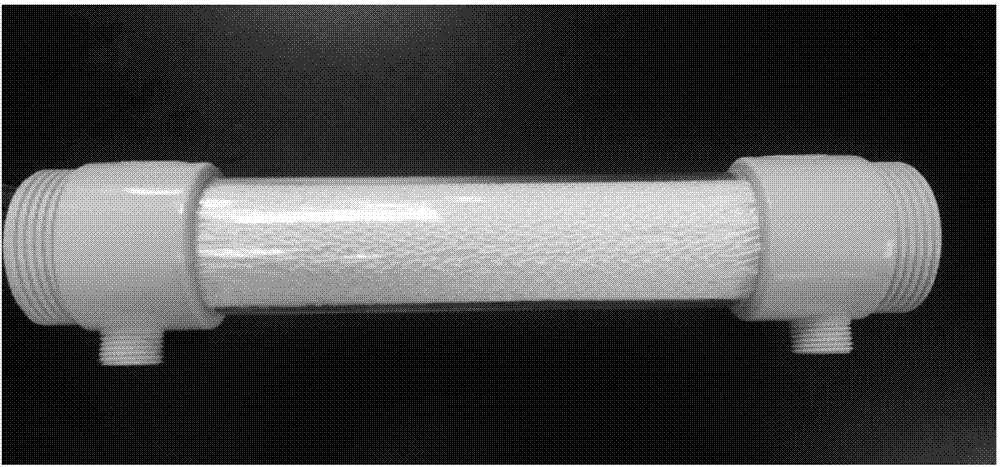

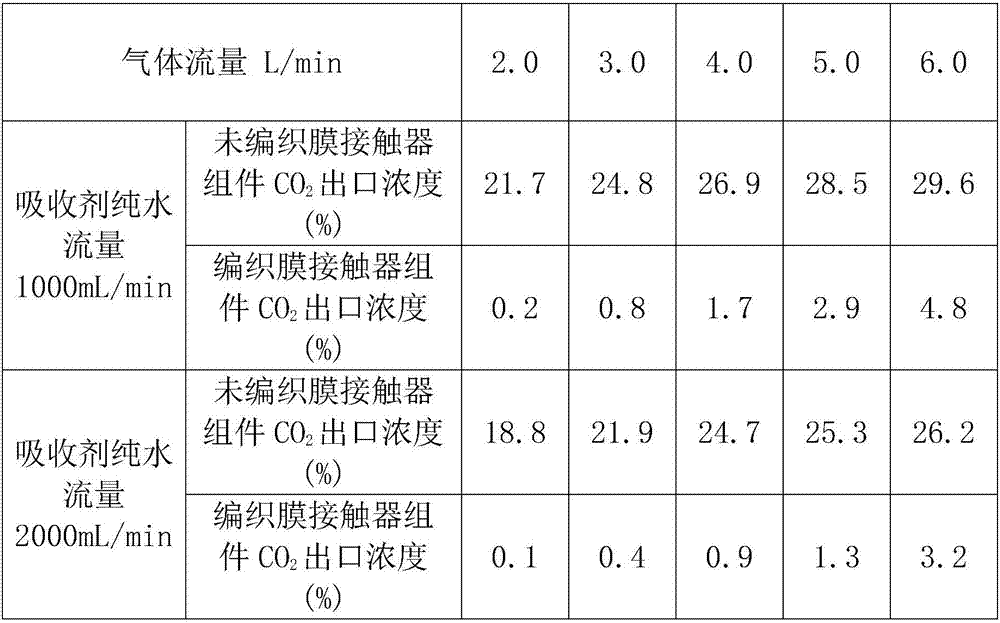

[0025] CO in biogas using polypropylene (PP) hollow fiber membrane contactor 2 to absorb. The specifications of the membrane filaments used are as follows: inner diameter 0.3mm, outer diameter 0.5mm, average pore diameter 0.2μm; the specific parameters of the module are as follows: the inner diameter of the module is 25.0mm, the length is 500mm, the packing density is 54%, and the effective membrane area is 1.06m 2 ; Among them, the membrane filament adopts two configurations: braided (braided membrane filament is divided into 3 strands, 1 strand for each strand, and the braiding angle is 30°) and unwoven (ie, traditional straight type). Biogas composition is 60% CH 4 +40%CO 2 , the absorbent is pure water, the flow rates are 1000mL / min and 2000mL / min respectively, the operating pressure is 0.8MPa, the gas goes through the tube side, and the pure water goes through the shell side. CO in product gas 2 The concentration was determined by gas chromatography, and the specific ...

Embodiment 2

[0030] Membrane distillation was performed using polytetrafluoroethylene (PTFE) hollow fiber membrane contactors. The specifications of the membrane used are as follows: inner diameter 0.8mm, outer diameter 1.6mm, average pore diameter 0.3μm; module specific parameters are as follows: module inner diameter 70.0mm, length 300mm, packing density 45%, effective membrane area 1.30m 2 ; Among them, the membrane silk adopts two configurations: braided (braided membrane silk is divided into 4 strands, 2 strands per share, and the braiding angle is 45°) and unwoven (ie, traditional straight type). The raw water is tap water, going through the shell side, the flow rate is 50L / h, the conductivity is 806μs / cm, the operating temperature is 70°C, the tube side is vacuumed, and the vacuum degree is -0.09MPa. The conductivity of the produced water was measured with a conductivity meter, and the specific results are shown in Table 2.

[0031] It can be seen that the braiding of the membrane ...

Embodiment 3

[0035] Ammonia nitrogen wastewater treatment process using polytetrafluoroethylene (PTFE) hollow fiber membrane contactor. The specifications of the membrane filaments used are as follows: inner diameter 0.5mm, outer diameter 1.0mm, average pore diameter 0.4μm; module specific parameters are as follows: module inner diameter 40.0mm, length 500mm, packing density 50%, effective membrane area 1.26m 2 ; Among them, the membrane filament adopts two configurations: braided (braided membrane filament is divided into 3 strands, 3 strands per strand, and the braiding angle is 40°) and unwoven (ie, traditional straight type). The wastewater with an ammonia nitrogen content of 2000ppm goes through the shell side with a flow rate of 6L / h, and the 10% sulfuric acid solution goes through the tube side with a flow rate of 3L / h. The specific test results are shown in Table 3.

[0036] It can be seen that whether the membrane yarn is woven or not has a very significant impact on the treatment...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com