Functionally gradient covalent organic framework membrane as well as preparation and application

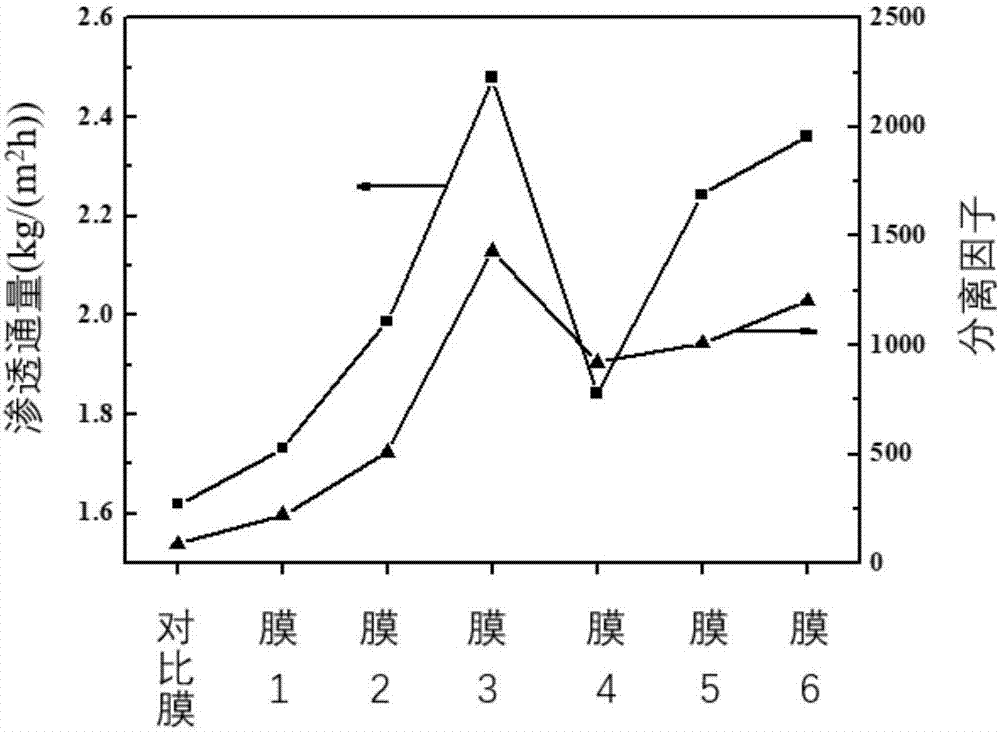

A covalent organic framework, functional gradient technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of affecting membrane stability, easy formation of defects, poor interface interaction, etc., and achieve good operational stability. The effect of stability, high selectivity and good interface compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

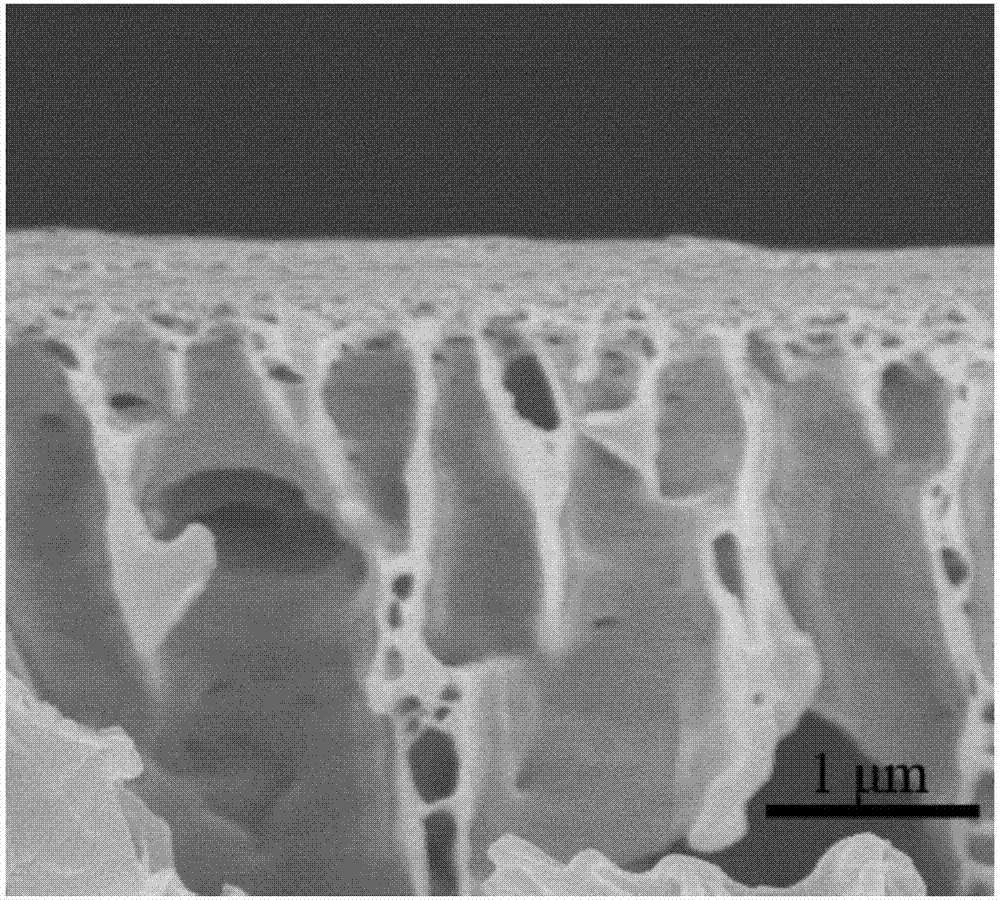

Embodiment 1

[0020] Embodiment 1, the preparation of a functionally graded covalent organic framework composite membrane, the steps are as follows:

[0021] Step 1) Preparation of covalent organic framework TpHZ: Dissolve 0.18g of 1,3,5-triformylpyroglucinol in 30mL of 1,3,5-trimethylbenzene / ethanol (v:v=1:1) solvent, Then 0.27 g of hydrazine hydrate was added. The system was sealed and heated to 120°C in a nitrogen atmosphere, and reacted for 48 hours to obtain a reddish-brown precipitate. The product was successively washed with anhydrous tetrahydrofuran, anhydrous acetone and anhydrous dichloromethane by centrifugation, and then vacuum-dried at 120° C. for 24 hours to obtain a red powder. Place the dried product in a mortar, add 3-5 drops of methanol and grind for 60 min. The ground product was dissolved in methanol, washed by centrifugation, and vacuum-dried at 40°C for 24 hours to obtain the final covalent organic framework TpHZ, which had a lateral dimension of 200 nm, a sheet thic...

Embodiment 2

[0023] Embodiment 2, the preparation of a functionally graded covalent organic framework composite membrane, the steps are as follows:

[0024] Step 1) Preparation of covalent organic framework TpHZ: Dissolve 0.24 g of 1,3,5-triformylpyroglucinol in 30 mL of 1,3,5-trimethylbenzene / ethanol (v:v=1:1) solvent, Then 0.36 g of hydrazine hydrate was added. The system was sealed and heated to 120°C in a nitrogen atmosphere, and reacted for 48 hours to obtain a reddish-brown precipitate. The product was successively washed with anhydrous tetrahydrofuran, anhydrous acetone and anhydrous dichloromethane by centrifugation, and then vacuum-dried at 120° C. for 24 hours to obtain a red powder. Place the dried product in a mortar, add 3-5 drops of methanol and grind for 60 min. The ground product was dissolved in methanol, washed by centrifugation, and vacuum-dried at 40°C for 24 hours to obtain the final product covalent organic framework TpHZ, which had a lateral dimension of 250 nm, a ...

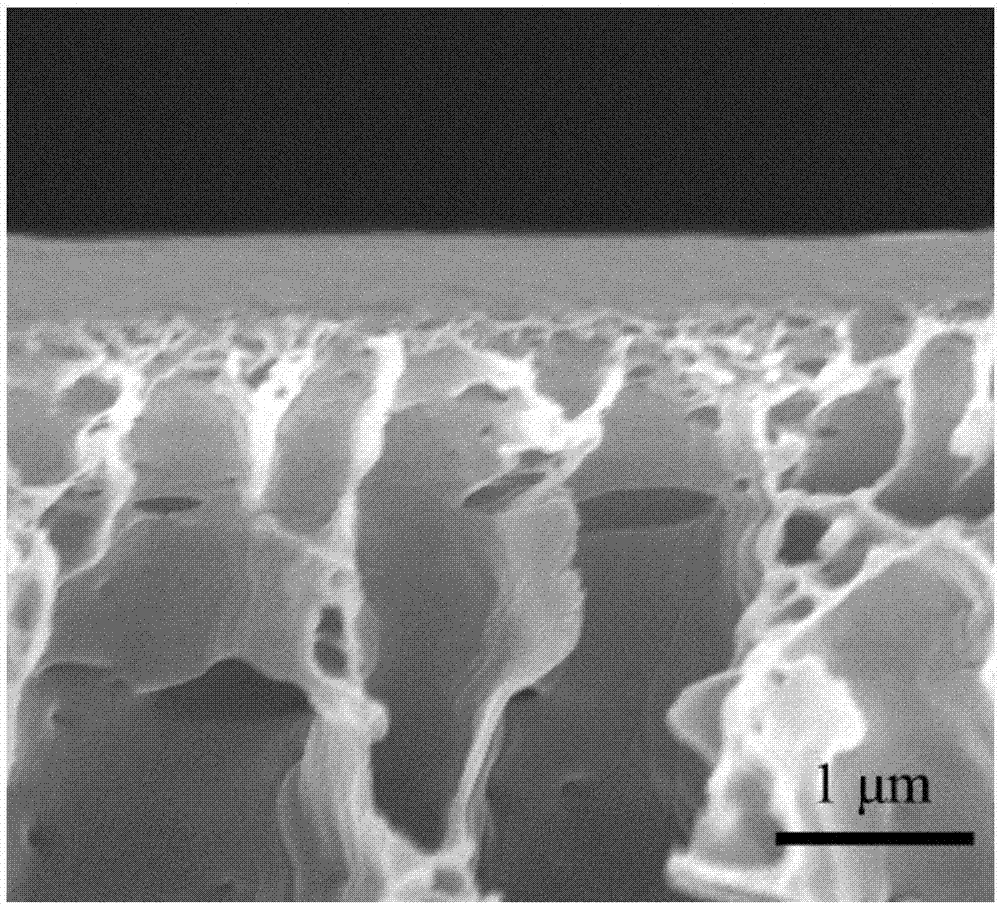

Embodiment 3

[0026] Example 3, the preparation of a functionally graded covalent organic framework composite membrane, the steps are as follows:

[0027]Step 1) Preparation of covalent organic framework TpHZ: Dissolve 0.3g of 1,3,5-triformylpyroglucinol in 30mL of 1,3,5-trimethylbenzene / ethanol (v:v=1:1) solvent, Then 0.45 g of hydrazine hydrate was added. The system was sealed and heated to 120°C in a nitrogen atmosphere, and reacted for 48 hours to obtain a reddish-brown precipitate. The product was successively washed with anhydrous tetrahydrofuran, anhydrous acetone and anhydrous dichloromethane by centrifugation, and then vacuum-dried at 120° C. for 24 hours to obtain a red powder. Place the dried product in a mortar, add 3-5 drops of methanol and grind for 60 min. The ground product was dissolved in methanol, washed by centrifugation, and dried in vacuum at 40°C for 24 hours to obtain the final product TpHZ, which had a lateral dimension of 320 nm, a sheet thickness of 5.5 nm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com