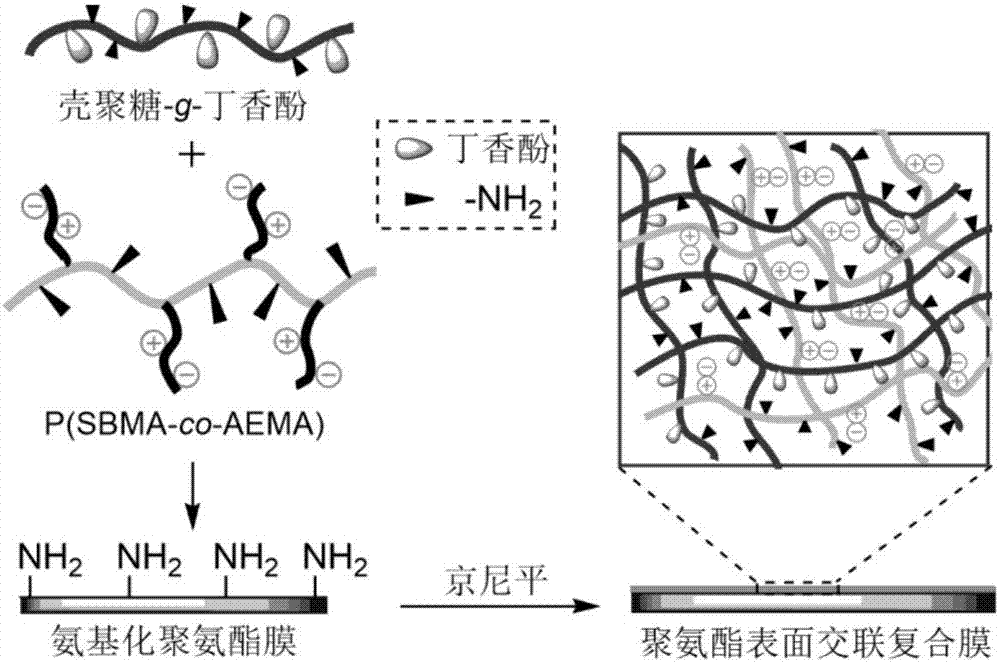

Antibacterial and antifouling double-functional polyurethane surface crosslinking composite film and preparation method thereof

A polyurethane film, polyurethane technology, applied in the field of biomedical materials, achieves good cell compatibility and blood compatibility, broad application prospects, and the effect of reducing the amount of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

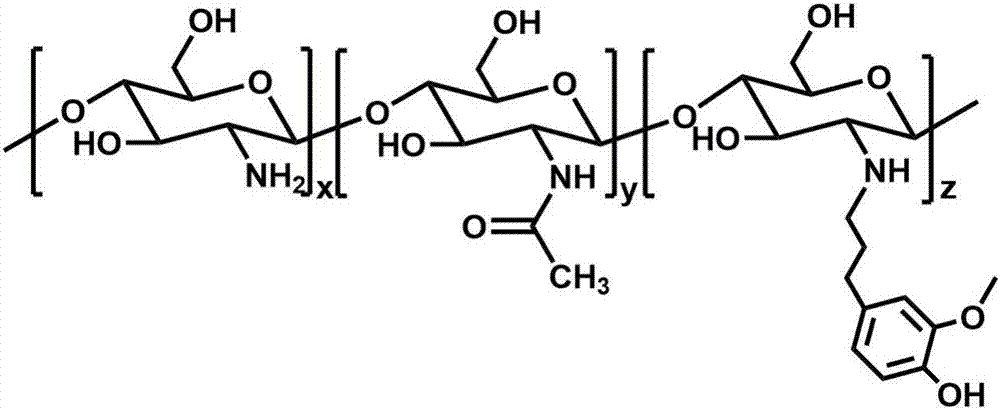

[0024] (1) preparation of chitosan-g-eugenol:

[0025] Weigh 1g chitosan (M n =20kDa) was dissolved in 35mL 2% (v / v) hydrochloric acid aqueous solution, 408.5mg eugenol (40% of chitosan amino molar weight) was dissolved in 20mL ethanol, after the two were mixed evenly, cerium ammonium nitrate was dissolved in 25mL of 1M nitric acid aqueous solution forms a solution with a concentration of 6mM and adds it to the above system, and reacts at 40°C under N 2 Under atmosphere for 6h. After the reaction, the product was precipitated in acetone, washed three times with methanol, then dissolved in deionized water, dialyzed for three days and lyophilized.

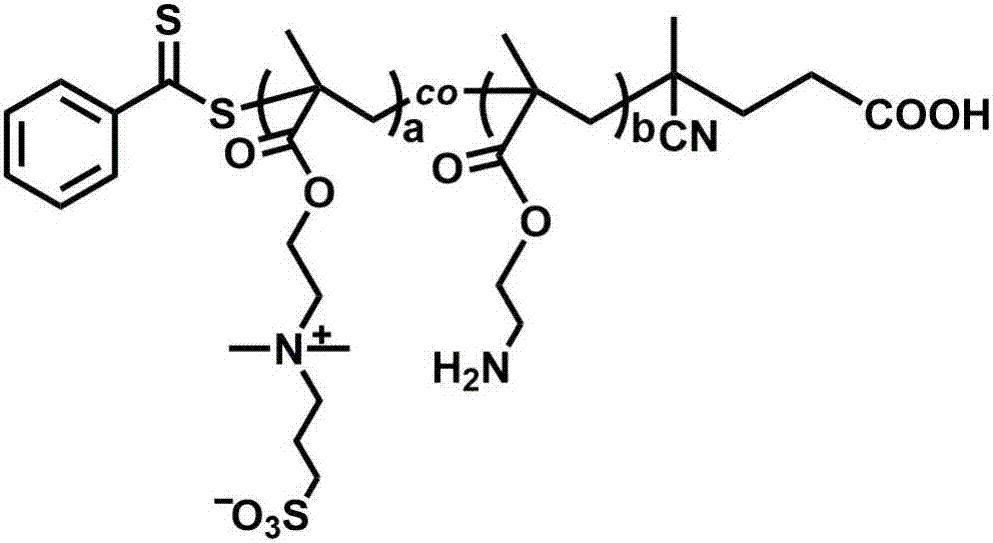

[0026] (2) Synthesis of P(SBMA-co-AEMA) copolymer:

[0027] According to the molar ratio of 36:12:1:0.2, weigh the monomer 1005.8mg sulfobetaine methacrylate, 198.7mg 2-aminoethyl methacrylate, 28mg chain transfer agent 4-cyanovaleric acid di Thiobenzoic acid, 3.3mg initiator azobisisobutyronitrile; be dissolved in 4.8mL methanol...

Embodiment 2

[0032] (1) synthesis of chitosan-g-eugenol:

[0033] Weigh 1g chitosan (M n =10kDa) was dissolved in 35mL 2% (v / v) hydrochloric acid aqueous solution, 306.4mg eugenol (30% of chitosan amino molar weight) was dissolved in 20mL ethanol, after the two were mixed evenly, cerium ammonium nitrate was dissolved in 25mL of 1M nitric acid aqueous solution to form a solution with a concentration of 4mM was added to the above system, and the reaction was carried out at 30°C under N 2 Under atmosphere for 4h. After the reaction, the product was precipitated in a large amount of acetone, washed three times with methanol, then dissolved in deionized water, dialyzed for three days and lyophilized.

[0034] (2) Synthesis of P(SBMA-co-AEMA) copolymer:

[0035] According to the molar ratio of 30:10:1:0.2, 838.2 mg of monomer sulfobetaine methacrylate, 165.6 mg of 2-aminoethyl methacrylate, 28 mg of chain transfer agent 4-cyanovaleric acid di Thiobenzoic acid, 3.3mg initiator azobisisobutyroni...

Embodiment 3

[0039] (1) preparation of chitosan-g-eugenol:

[0040] Weigh 1g chitosan (M n =40kDa) was dissolved in 35mL 2% (v / v) hydrochloric acid aqueous solution, 408.5mg eugenol (40% of chitosan amino molar weight) was dissolved in 20mL ethanol, after the two were mixed evenly, cerium ammonium nitrate was dissolved in 25mL of 1M nitric acid aqueous solution forms a solution with a concentration of 5mM and adds it to the above system, and reacts at 35°C under N 2 Under atmosphere for 5h. After the reaction, the product was precipitated in a large amount of acetone, washed three times with methanol, then dissolved in deionized water, dialyzed for three days and lyophilized.

[0041] (2) Synthesis of P(SBMA-co-AEMA) copolymer:

[0042] According to the molar ratio of 36:12:1:0.2, weigh the monomer 1005.8mg sulfobetaine methacrylate, 198.7mg 2-aminoethyl methacrylate, 28mg chain transfer agent 4-cyanovaleric acid di Thiobenzoic acid, 3.3mg initiator azobisisobutyronitrile; be dissolved...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com