Method for Purifying Ethylene Glycol

A technology of ethylene glycol and crude products, which is applied in chemical instruments and methods, preparation of organic compounds, separation/purification of hydroxyl compounds, etc., can solve the problems of low UV transmittance and poor quality, and achieve improved UV transmittance , less impurities, and improve the effect of UV transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

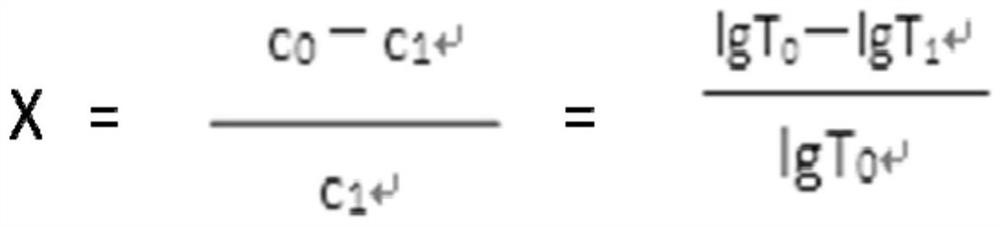

Image

Examples

preparation example 1

[0048] Preparation of composite hydrogenation catalyst CAT-1:

[0049] (1) 100 mass parts of liquid epoxy resin (Baling Petrochemical, CYD-128), 85 mass parts of curing agent methyltetrahydrophthalic anhydride (MeTHPA) (Guangdong Shengshida Technology and Trade Co., Ltd.), curing accelerator triethanolamine (TEA) (Tianjin Chemical Reagent No. 1 Factory) 1.5 parts by mass were stirred evenly;

[0050] (2) take by weighing the epoxy curing system prepared in 40g step (1) and 180g nickel-aluminum alloy powder and fully stir and mix, Ni content is 48wt% in the nickel-aluminum alloy powder, and aluminum content is 52wt%, gets appropriate mixture and joins in In the cylindrical mould, press with a flat vulcanizer for 30mins at a temperature of 120°C and a pressure of 7MPa, then press with a flat vulcanizer for 90mins at a temperature of 150°C and a pressure of 7MPa, and take it out after cooling to obtain a granular catalyst precursor;

[0051] (3) Measure 100ml of catalyst precurs...

preparation example 2

[0054] Preparation of composite hydrogenation catalyst CAT-2:

[0055] (1) 100 mass parts of liquid epoxy resin (Baling Petrochemical, CYD-128), 85 mass parts of curing agent methyltetrahydrophthalic anhydride (MeTHPA) (Guangdong Shengshida Technology and Trade Co., Ltd.), curing accelerator triethanolamine (TEA) (Tianjin Chemical Reagent No. 1 Factory) 1.5 parts by mass were stirred evenly;

[0056] (2) Take by weighing 50g of the epoxy curing system prepared in step (1) and 150g of nickel-aluminum alloy powder and fully stir and mix, the Ni content in the nickel-aluminum alloy is 48wt%, and the aluminum content is 52wt%, and an appropriate amount of mixture is added to the cylinder In the shaped mold, press with a flat vulcanizer for 30mins at a temperature of 120°C and a pressure of 7MPa, and press for 90mins with a flat vulcanizer at a temperature of 150°C and a pressure of 7MPa, and take it out after cooling to obtain a granular catalyst precursor;

[0057] (3) Measure 1...

Embodiment 1

[0060] The ethylene glycol liquid first passes through the bed of coconut shell charcoal at a temperature of 30°C and normal pressure, and the space velocity of the ethylene glycol liquid phase is 6.0h -1 ; Then put the composite hydrogenation catalyst CAT-1 50ml into the fixed bed reactor, use the fixed bed reactor for hydrogenation refining, the inner diameter of the tube is 25mm, the hydrogen flow rate is 200ml / min, the reaction temperature is 100°C, the pressure is 0.5MPa, Alcohol liquid space velocity 6.0h -1 , UV light transmittance of raw materials before hydrogenation: 0.1% at 220nm, after hydrogenation, the ultraviolet light transmittance of the product was measured with a UV spectrophotometer, see Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com