A kind of oligomeric anionic sulfonate surfactant, its preparation method and application

An anionic sulfonate and surfactant technology, which is applied in the preparation of sulfonate, chemical instruments and methods, and the preparation of organic compounds, can solve the problems of limited molecular structure diversity, reduced yield, and difficult processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

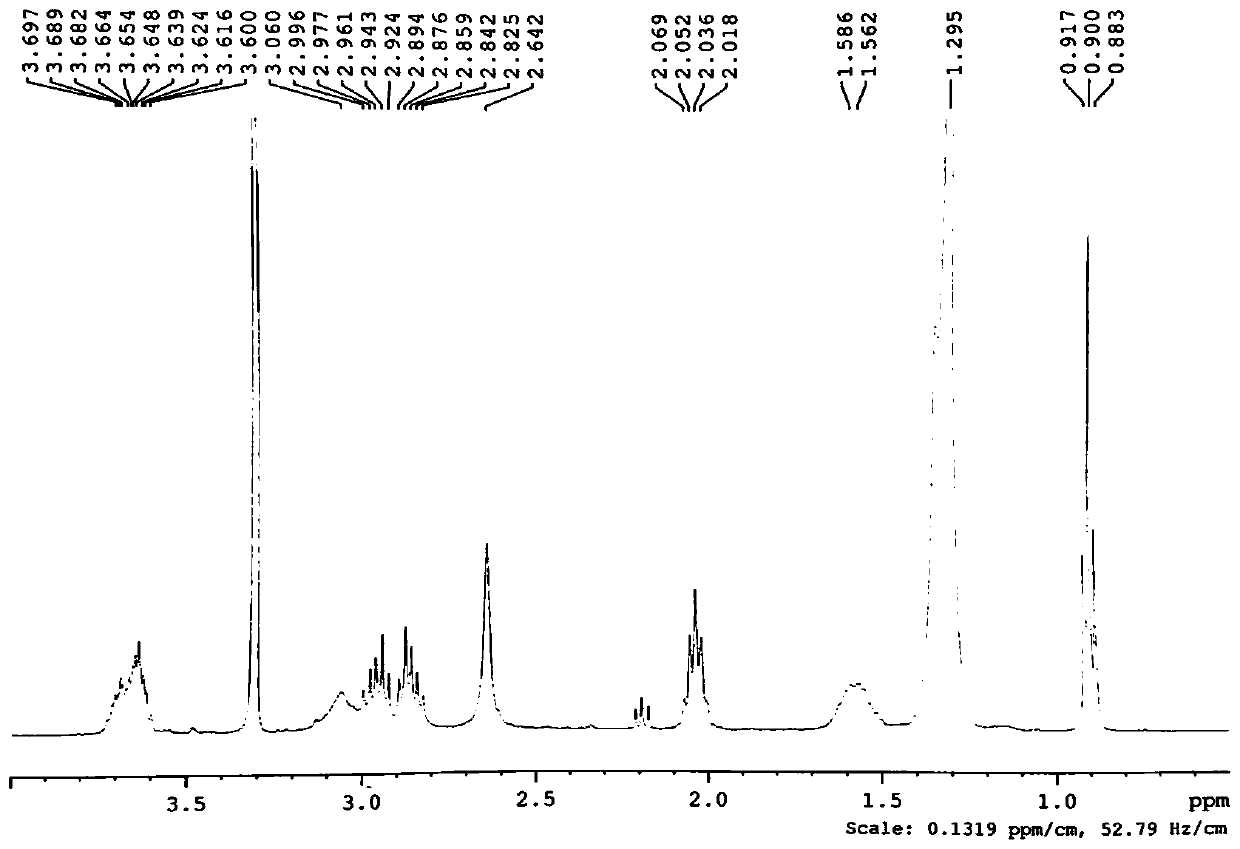

[0072] Dipolyanion sulfonate DMEDA-(C 12 SO 3 Na) 2 Preparation of:

[0073]

[0074] (1) Synthesis steps of the intermediate product dimer alcohol: add 0.9g (10.0mmol) of N,N'-dimethylethylenediamine to 6.4g (30.0mmol) of 1,2-epoxytetradecane Ethanol (50ml) solution was reacted at 90°C for 24h. After the reaction, use a rotary evaporator to remove the absolute ethanol solvent, dissolve the crude product in chloroform, and then pass through a silica gel chromatography column with chloroform / methanol for purification and vacuum drying to obtain the intermediate dimer alcohol.

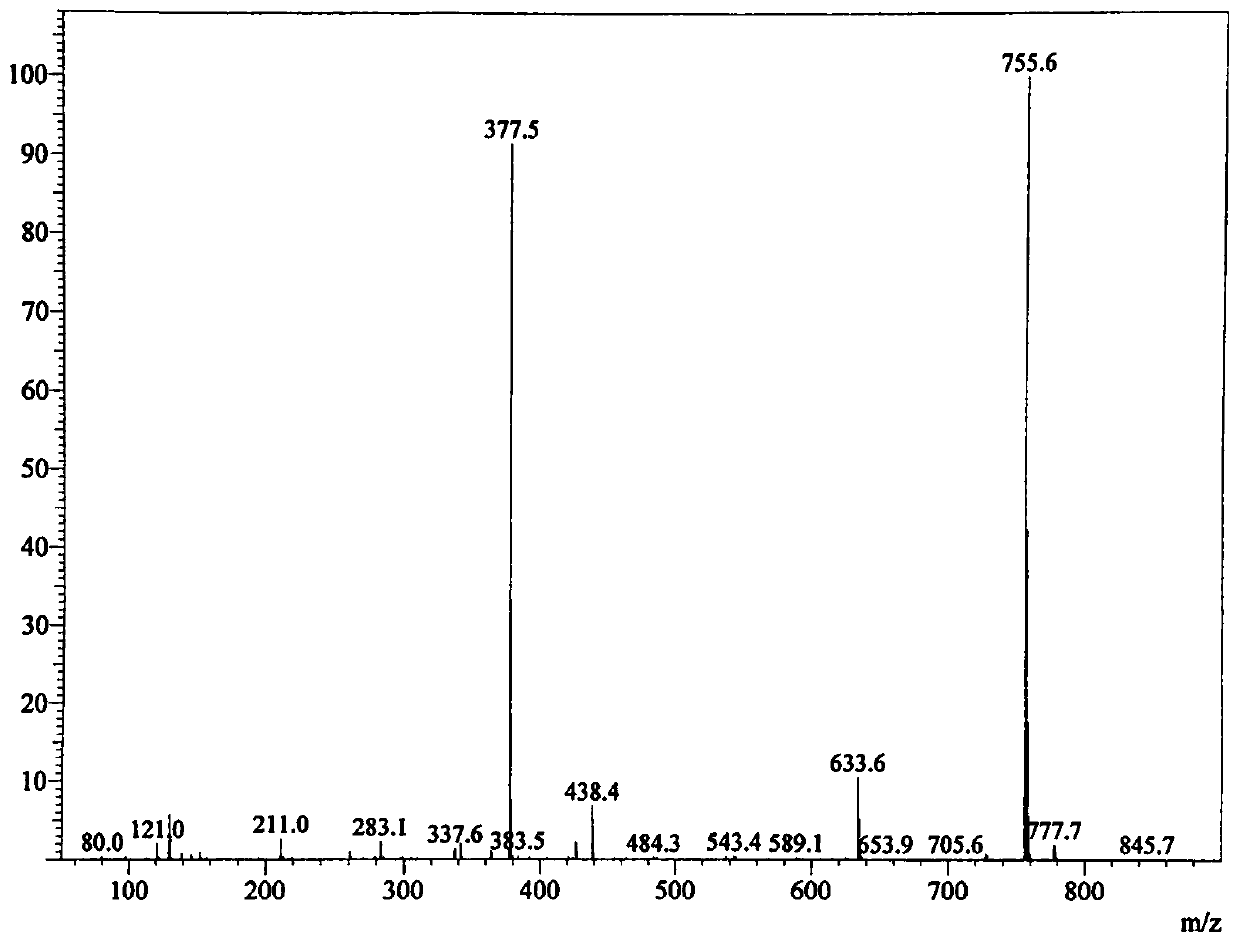

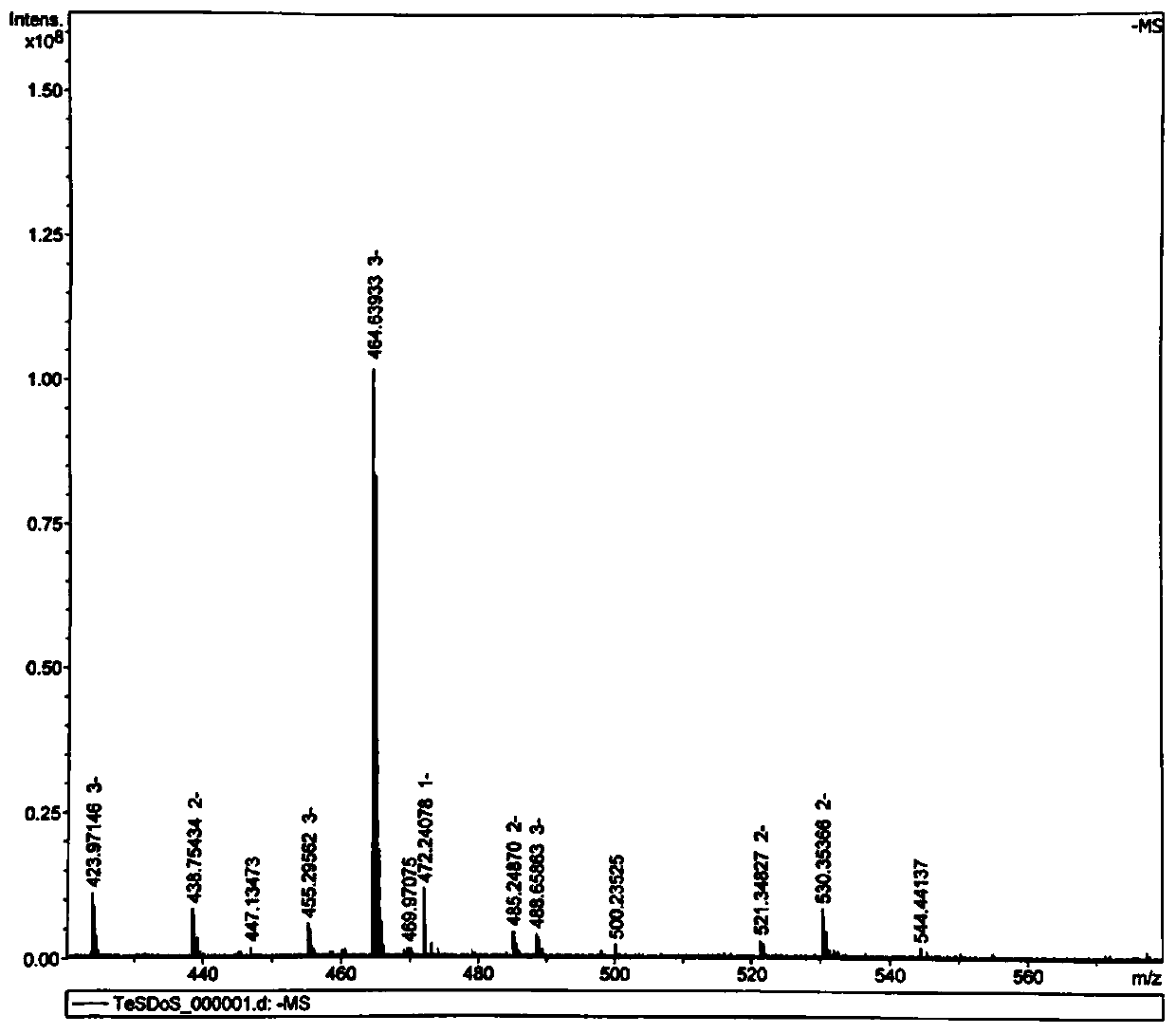

[0075] The intermediate dimer alcohol was characterized by MALDI-TOF: 513.5 (M+H).

[0076] (2) Dipolyanionic sulfonate surfactant DMEDA-(C 12 SO 3 Na) 2 The synthesis steps of the method: take 0.3g (60%, 7.5mmol) of sodium hydride, 1.0g (8.2mmol) of 1,3-propane sultone, and 0.5g (1.0mmol) of the intermediate dimer alcohol, dissolve them in THF, and reflux 48h, then add methanol to end the rea...

Embodiment 2

[0079] Tetrapolyanionic sulfonate surfactant EDA-(C 12 SO 3 Na) 4 Preparation of:

[0080]

[0081] (1) Synthetic steps of intermediate product tetramer alcohol: ethylenediamine 0.6g (10.0mmol) is joined in the dehydrated alcohol (50ml) solution of 1,2-epoxytetradecane 12.7g (60.0mmol) at 90 Reaction at ℃ for 24h. After the reaction, the absolute ethanol solvent was removed with a rotary evaporator, and the crude product was dissolved in chloroform, then eluted with chloroform / methanol through a silica gel chromatography column, refined and vacuum-dried to obtain white powdery intermediate IV. Polyol, 99% yield.

[0082] MALDI-TOF characterizes the intermediate tetramer: 910.1 (M+H).

[0083] (2) Tetrapolyanionic sulfonate surfactant EDA-(C 12 SO 3 Na) 4 The synthesis steps of the method: take 0.6g (60%, 15.0mmol) of sodium hydride, 2.0g (16.4mmol) of 1,3-propane sultone, and 0.9g (1.0mmol) of the intermediate tetramer alcohol, dissolve them in THF, and reflux 48h,...

Embodiment 3

[0086] Hexameric anionic sulfonate surfactant TAEA-(C 12 SO 3 Na) 6 Preparation of:

[0087]

[0088] (1) Synthetic steps of the intermediate product hexamerol: the dehydrated alcohol ( 50ml) solution at 90°C for 24h. After the reaction, use a rotary evaporator to remove the absolute ethanol solvent, dissolve the crude product in chloroform, then pass through a silica gel chromatography column with chloroform / methanol for purification and vacuum drying to obtain the intermediate hexamerol.

[0089] The intermediate hexamer alcohol was characterized by MALDI-TOF: 1420.6 (M+H).

[0090] (2) Hexameric anionic sulfonate surfactant TAEA-(C 12 SO 3 Na) 6 Synthetic steps of the method: take 1.0g (60%, 25mmol) of sodium hydride, 2.9g (23.7mmol) of 1,3-propanesultone, and 1.4g (1.0mmol) of the intermediate hexamerol, dissolve them in THF, and reflux for 48h , and then methanol was added to terminate the reaction. The solvent was removed by rotary evaporation, and the crude ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com