Preparation method of sensor electrode surface anti-biological-pollution coating

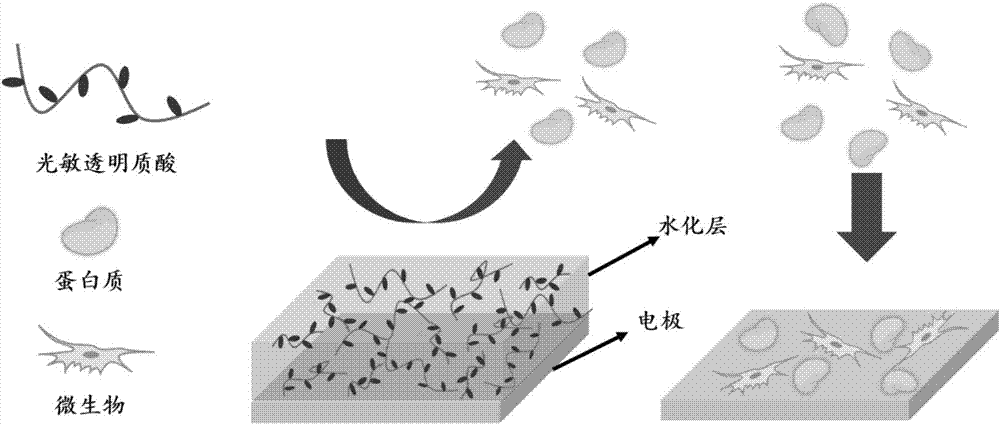

An anti-biological pollution, sensor electrode technology, applied in the direction of electrochemical variables of materials, etc., can solve the problems of blood component metabolism detection error, blood sample centrifugation pollution, unable to fully express the real situation, etc., to achieve long-term stable anti-biological pollution ability, Strong anti-biological pollution ability and the effect of inhibiting non-specific adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method for an anti-biological contamination coating on the surface of a sensor electrode, comprising the following specific steps:

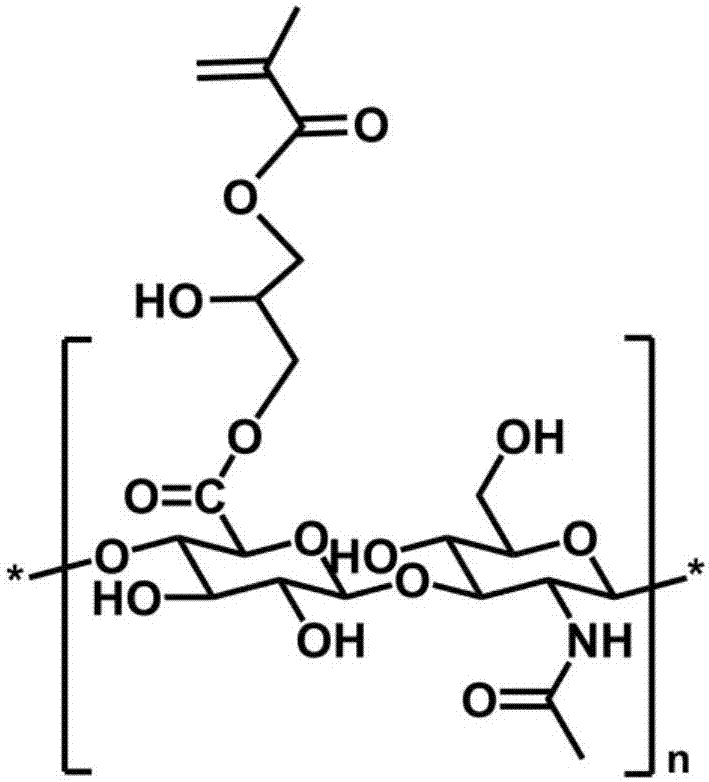

[0029] (1) Synthesis of photosensitive hyaluronic acid

[0030] Dissolve 1.0g of hyaluronic acid (HA) in water and stir until completely dissolved to form an aqueous solution of hyaluronic acid; add 4-dimethylaminopyridine (DMAP) (40% mol. relative to the number of HA repeating units), formazan Glycidyl acrylate (GMA) (10 times the number of HA repeating units), tetrabutylammonium bromide (TBAB) (80% mol. relative to the number of HA repeating units), react at room temperature for 48h; precipitate the reaction solution with acetone , transferred to a dialysis bag for dialysis against water for 4 days; the dialysis solution was freeze-dried to obtain photosensitive hyaluronic acid HA-GMA, which was stored away from light for later use;

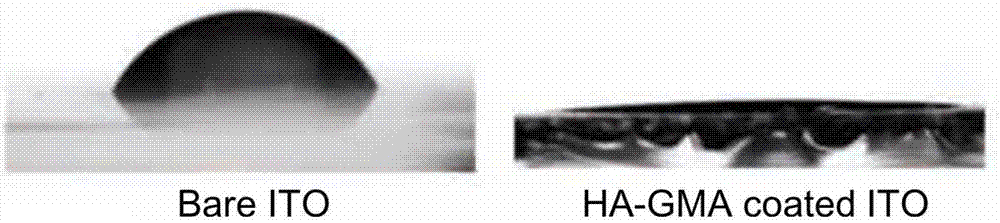

[0031] (2) Preparation of anti-biological contamination coating

[0032] Dissolve 50mg o...

Embodiment 2

[0034] A preparation method for an anti-biological contamination coating on the surface of a sensor electrode, comprising the following specific steps:

[0035] (1) Synthesis of photosensitive hyaluronic acid

[0036] Dissolve 0.5g of hyaluronic acid (HA) in water and stir until completely dissolved to form an aqueous solution of hyaluronic acid; sequentially add 4-dimethylaminopyridine (DMAP) (100% mol. relative to the number of HA repeating units), formazan Glycidyl acrylate (GMA) (5 times the number of HA repeating units), tetrabutylammonium bromide (TBAB) (100% mol. relative to the number of HA repeating units), react at room temperature for 24h; precipitate the reaction solution with acetone , transferred to a dialysis bag for dialysis against water for 7 days; freeze-dried the dialyzed solution to obtain photosensitive hyaluronic acid HA-GMA, and stored it away from light for later use;

[0037] (2) Preparation of anti-biological contamination coating

[0038] Dissolve...

Embodiment 3

[0040] A preparation method for an anti-biological contamination coating on the surface of a sensor electrode, comprising the following specific steps:

[0041] (1) Synthesis of photosensitive hyaluronic acid

[0042]Dissolve 1g of hyaluronic acid (HA) in water and stir until completely dissolved to form an aqueous solution of hyaluronic acid; add 4-dimethylaminopyridine (DMAP) (200% mol. relative to the number of HA repeating units), methyl Hydroxyethyl acrylate (HEMA) (20 times the number of HA repeating units), tetrabutylammonium bromide (TBAB) (400% mol. relative to the number of HA repeating units), reacted at room temperature for 12h; the reaction solution was precipitated with acetone, Transfer to a dialysis bag for dialysis against water for 7 days; freeze-dry the dialyzed solution to obtain photosensitive hyaluronic acid HA-HEMA, and store it away from light for later use;

[0043] (2) Preparation of anti-biological contamination coating

[0044] Dissolve 100 mg of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com