Preparation method of easily-preserved marine small trash enzymolysis full-fish cream rich in small peptides

A small miscellaneous fish, enzymatic hydrolysis technology, applied in the field of protein enzymatic hydrolysis, can solve the problems of reduced activity, easy deterioration, difficulty in continuous and automatic enzymatic reactions, etc., and achieve the effect of reducing enzymatic hydrolysis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A preparation method for enzymatically hydrolyzed whole fish paste of small marine miscellaneous fish rich in small peptides, which is easy to preserve, comprising the following steps:

[0055] 1) Granulation, using fresh seafood small miscellaneous fish as raw material, freeze-drying to a water content of 50wt%-70wt%, grading and pulverizing to protein particles with a maximum size of less than 5mm, and storing in dry bulk and freezing;

[0056] 2) Micronization, add pure water at 0-3°C to the protein granules according to the mass ratio of protein granules to water 1:0.2, shear at ultra-high speed to a protein granule slurry above 150 mesh, add pure water to the mass ratio of raw fish and water 1:0.2~10.

[0057] More preferably, the mass ratio of feed to water is 1:0.5-5.

[0058] Specifically, the rotation diameter of the shearing blade is 20-40 mm, the motor speed is above 30,000 revolutions, a conical gathering cover is arranged around the blade, and the inner wa...

Embodiment 2

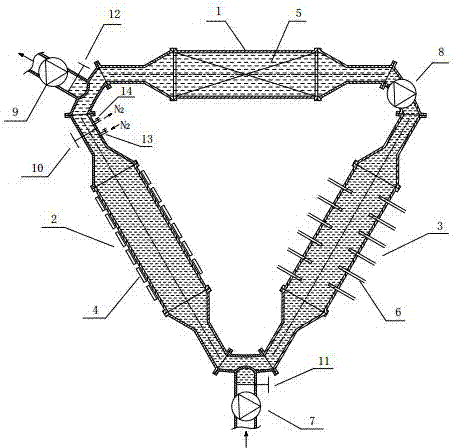

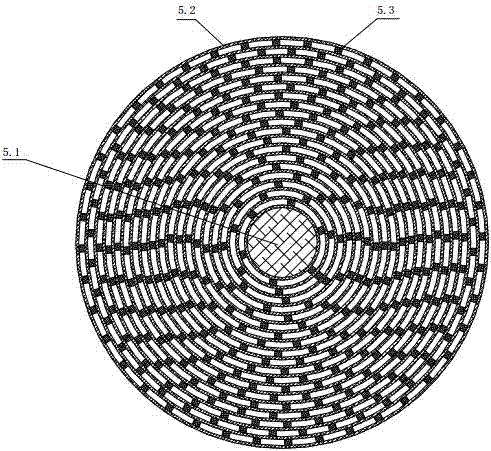

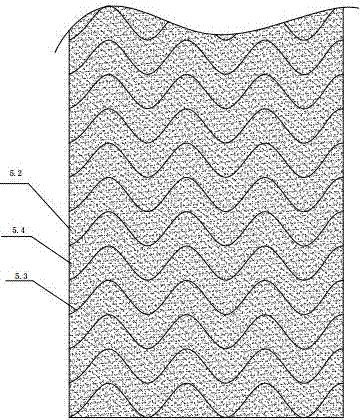

[0083] Such as figure 2 , 3 As shown, in step 4), the preform is a film 5.3, and a plurality of isolation ribs 5.4 are arranged at intervals on the upper surface of the film 5.3, and the isolation ribs 5.4 are sinusoidally spaced at the same period. The upper and lower surfaces of the film 5.3 are evenly bonded with silicon nuclease particles, and the concentration of the immobilized enzyme is determined by the biquinoline formic acid method, reaching 2-3 μg / cm 2 , Practice has proved that the immobilized enzyme has good activity. The film 5.3 is wound around the outer peripheral surface of the shaft 5.1 to form a pre-rolled body 5 with a certain diameter, and the pre-rolled body 5 is fixed in the cylindrical immobilized enzyme reactor 1 . Since the preset winding body 5 has a more compact interval, a sinusoidal curved path is provided between the isolation rib 5.4 and the upper and lower films, and the curved path extends the chance of the enzyme=protease contacting the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com