Method for constructing three-dimensional electrocatalyst by using phosphorus-doped nanosheet array

A nanosheet array, phosphorus-doped technology, applied in chemical instruments and methods, physical/chemical process catalysts, electrodes, etc., can solve the problem that electrocatalytic performance cannot meet industrial production, and achieve stable structure, mild reaction conditions, The effect of improving activity and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

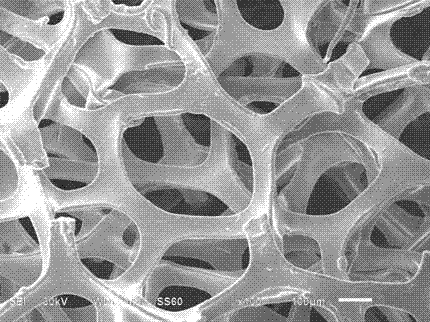

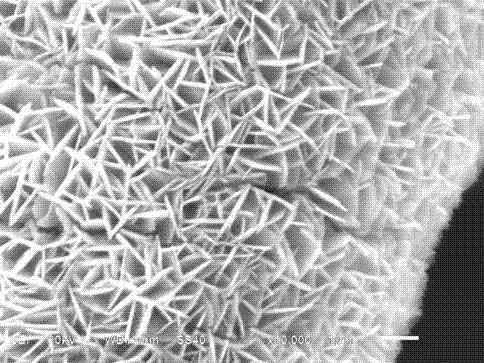

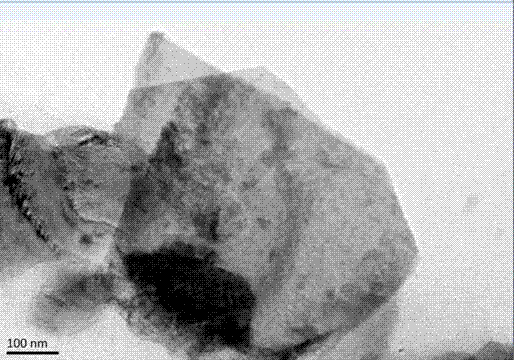

[0034] A method for constructing a three-dimensional electrocatalyst by a phosphorus-doped nanosheet array, by growing an array of nickel disulfide nanosheets with bifunctional activity on a larger-sized nickel foam with a three-dimensional porous structure, and further doping with anion phosphorus impurity, improve the activity in the two electrochemical reactions of hydrogen evolution and oxygen evolution.

[0035] A method for constructing a three-dimensional electrocatalyst by a phosphorus-doped nanosheet array, the preparation steps are as follows:

[0036] 1. Carry out surface pretreatment to nickel foam with hydrochloric acid and acetone to remove the oxide layer and impurities on the surface of nickel foam;

[0037] Two, take a certain amount of thiourea and nickel chloride, and disperse them in a container equipped with deionized water, fully disperse and dissolve under the action of ultrasonic and magnetic stirring to obtain a mixed solution;

[0038] 3. Add the mix...

Embodiment 2

[0043] As a preferred embodiment of Example 1, the surface pretreatment in step 1 refers to: cutting the nickel foam into rectangular pieces of 0.5*1 cm to 1*3 cm, placing them in hydrochloric acid solution, and ultrasonically washing them for 8 to 15 minutes. Then soak for 25 to 35 minutes, rinse with deionized water, place it in acetone solution, ultrasonically wash for 8 to 15 minutes, soak for 25 to 35 minutes, and then take it out for vacuum drying.

[0044] In the second step, the mass ratio of thiourea:nickel chloride is 1.2˜1.7:1.

[0045] In the third step, the mixed solution is immersed in the nickel foam, heated to 175-185° C. in a blast drying oven, and kept for 15-25 hours.

[0046] In the fifth step, the phosphorus-containing precursor and the nickel foam obtained in step four are placed in two porcelain boats, which are placed together in the quartz tube of the tube furnace, and the porcelain boat where the phosphorus-containing precursor is placed is located at...

Embodiment 3

[0048] As a kind of specific embodiment of embodiment 1:

[0049] 1) Cut the nickel foam into 1*3cm rectangular pieces, put it in hydrochloric acid solution, ultrasonically wash it for 10 minutes, then soak it for 30 minutes, then rinse it with deionized water, put it in acetone solution, and ultrasonically wash it for 10 minutes , soak for 30 minutes, then take out and vacuum dry;

[0050] 2) Prepare a mixed solution of 1.5 mM thiourea and 1 mM nickel chloride, and fully disperse and dissolve it under the action of magnetic stirring;

[0051] 3) Take 20 mL of the above solution and the nickel foam treated in step 1), transfer it to a polytetrafluoroethylene-lined reaction kettle, tighten the reaction kettle, place it in a blast drying oven, heat it to 180°C, and keep it warm for 20 hours , carry out a chemical reaction, and cool down naturally after the reaction;

[0052] 4) After cooling to room temperature, take out the reacted nickel foam, wash it, and dry it in a vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com