A kind of iminodisuccinic acid chelated metal salt

An iminodisuccinic acid and alloy technology, applied in the field of chelating metal salts and chelating agents, can solve the problems of reducing the content of active ingredients, increasing the risk of storage and transportation, and the corrosion effect of chloride ions, so as to improve the content and utilization rate, The application range is expanded and the safety is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of iminodisuccinic acid chelated metal salt comprises the steps:

[0032] a. After the aqueous solution of iminodisuccinate or iminodisuccinic acid salt with a concentration of 8% to 15% is treated with a strong acid type cation exchange resin, iminodisuccinic acid is obtained;

[0033] b. Add iminodisuccinic acid and raw materials containing metal elements in sequence in a reaction kettle filled with pure water. The molar ratio of iminodisuccinic acid to raw materials containing metal elements is 1:0.25~1, and iminodisuccinic acid When the acid reacts with a certain metal element-containing raw material alone, when the iminodisuccinic acid is 1 equivalent, the copper-containing raw material, magnesium-containing raw material and zinc-containing raw material are 1 equivalent, and the manganese-containing raw material is 0.5 equivalent. The reaction is the most complete when the iron raw material is 0.25 equivalents, and the final mass ratio of the...

Embodiment 1

[0037] A kind of iminodisuccinic acid chelated metal salt, its preparation method is as follows:

[0038] a. After the aqueous solution of iminodisuccinic acid sodium salt with a concentration of 8% is treated with a strong acid type cation exchange resin, iminodisuccinic acid is obtained;

[0039] b. Add iminodisuccinic acid and CuO in sequence in a reactor filled with pure water, the molar ratio of iminodisuccinic acid to CuO is 1:1, the total mass of iminodisuccinic acid and CuO is equal to the mass of water The ratio is 1:5, mix the raw materials thoroughly, heat to 40°C, and react for 2 hours;

[0040] c. Filtrate after the reaction, remove the filter residue, concentrate the liquid part until crystals appear, then centrifuge the water to obtain solid crystals, and dry the crystals to obtain iminodisuccinic acid chelated metal salts.

Embodiment 2~4

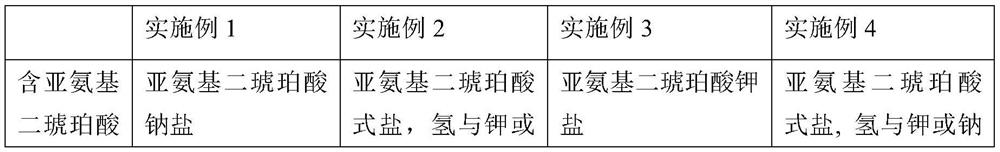

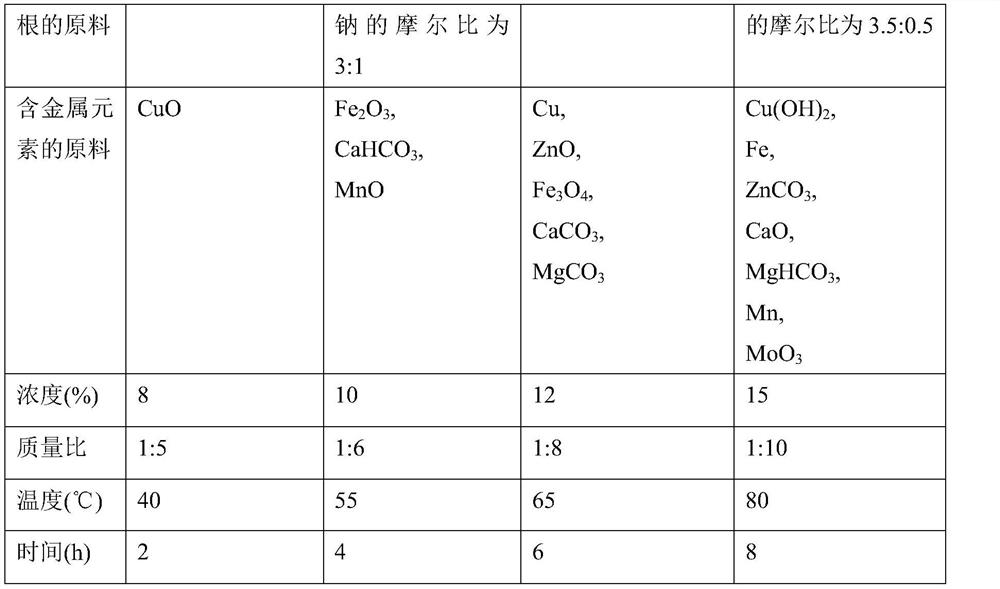

[0042] Embodiments 2-4 have the same reaction steps as that of Embodiment 1, and the different types and contents of the reaction raw materials, as well as the different process conditions are shown in Table 1 below. Wherein "concentration" represents the mass concentration of the aqueous solution of iminodisuccinic acid salt or iminodisuccinic acid salt in step a, and "mass ratio" is the total mass of iminodisuccinic acid and the raw material containing metal elements in step b With the mass ratio of water, "temperature" is the temperature heated in step b, and "time" is the reaction time of step b.

[0043] Table 1

[0044]

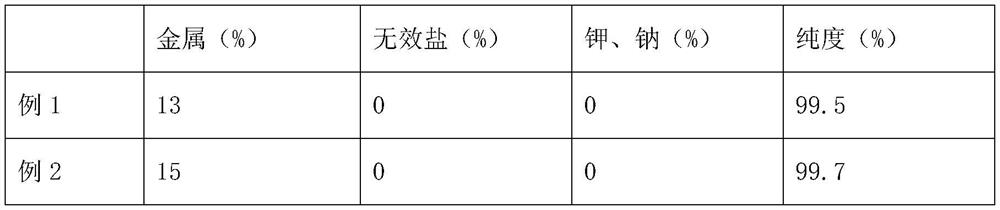

[0045]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com