Fiber reinforced high-density polyethylene/graphite/graphene composite material and preparation method thereof

A high-density polyethylene and fiber-reinforced technology, applied in the field of polyethylene materials, can solve undiscovered problems, achieve the effects of improving fluidity, enhancing binding force, and solving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

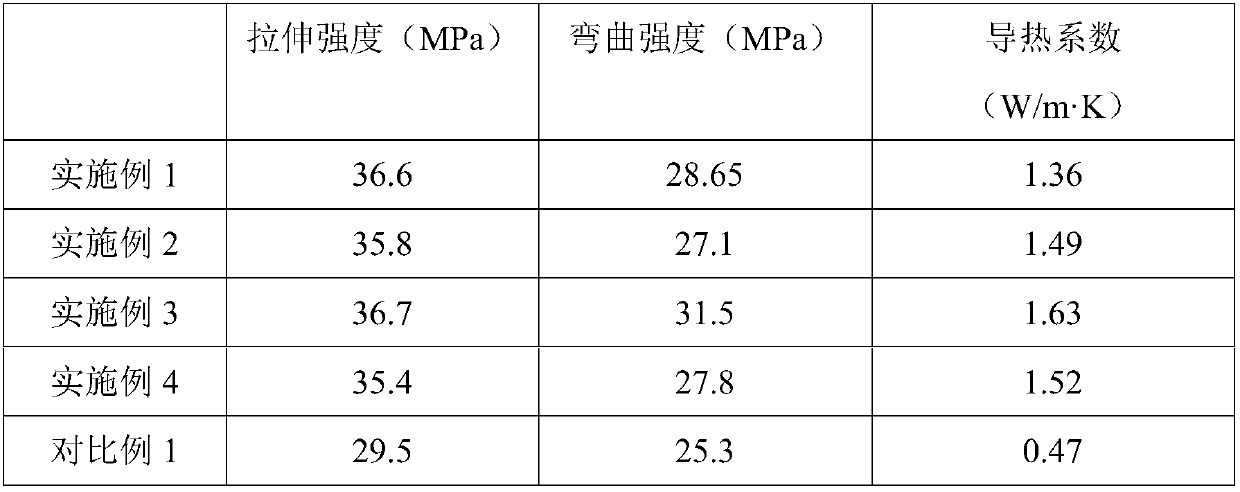

Examples

Embodiment 1

[0038] (1) Fiber-reinforced high-density polyethylene / graphite / graphene composites

[0039] Prepared by the following proportions by weight: 50 parts of natural plant fiber, 20 parts of graphite powder, 0.5 parts of graphene, 50 parts of polyolefin, 10 parts of foaming agent, 1 part of crosslinking agent, 8 parts of plasticizer, lubricant 10 parts, 10 parts of activator. In the present embodiment, natural plant fiber is jute fiber; Polyolefin is high-density polyethylene, polypropylene mixes by 1:1 mass ratio; Foaming agent is azodicarbonamide; Cross-linking agent is dicumyl peroxide ; The plasticizer is diethyl phthalate; the lubricant is polyethylene wax; the activator is zinc oxide.

[0040] (2) Preparation method of fiber-reinforced high-density polyethylene / graphite / graphene composite material

[0041] The preparation method of the fiber-reinforced high-density polyethylene / graphite / graphene composite material of the present embodiment comprises the following steps:

...

Embodiment 2

[0051] (1) Fiber-reinforced high-density polyethylene / graphite / graphene composites

[0052] Prepared by the following proportions by weight: 30 parts of natural plant fiber, 10 parts of graphite powder, 2 parts of graphene, 40 parts of polyolefin, 6 parts of foaming agent, 0.5 part of crosslinking agent, 5 parts of plasticizer, lubricant 1 part, 1 part activator. In the present embodiment, natural plant fiber is jute fiber; Polyolefin is high-density polyethylene, polypropylene mixes by 1:1 mass ratio; Foaming agent is azodicarbonamide; Cross-linking agent is dicumyl peroxide ; The plasticizer is diethyl phthalate; the lubricant is polyethylene wax; the activator is zinc oxide.

[0053] (2) Preparation method of fiber-reinforced high-density polyethylene / graphite / graphene composite material

[0054] The preparation method of the fiber-reinforced high-density polyethylene / graphite / graphene composite material of the present embodiment comprises the following steps:

[0055] S...

Embodiment 3

[0064] (1) Fiber-reinforced high-density polyethylene / graphite / graphene composites

[0065] Prepared by the following proportions by weight: 40 parts of natural plant fiber, 10 parts of graphite powder, 1 part of graphene, 60 parts of polyolefin, 8 parts of foaming agent, 1 part of crosslinking agent, 8 parts of plasticizer, lubricant 6 parts, 8 parts of activator. In the present embodiment, natural plant fiber is sisal fiber; Polyolefin is high-density polyethylene; Foaming agent is azodicarbonamide; Cross-linking agent is dicumyl peroxide, polyethylene glycol by 1:1 The mass ratio is mixed; the plasticizer is diethyl phthalate and acetyl tributyl citrate mixed in a mass ratio of 1:1; the lubricant is n-butyl stearate; the activator is magnesium oxide.

[0066] (2) Preparation method of fiber-reinforced high-density polyethylene / graphite / graphene composite material

[0067] The preparation method of this embodiment is basically the same as that of Example 1, the difference ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com