Preparation method and application of liquid feed

A technology for liquid feed and feed formulation, applied in the field of biotechnology and feed, can solve the problems that have not been effectively solved, low feed intake of piglets, reduced immunity, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

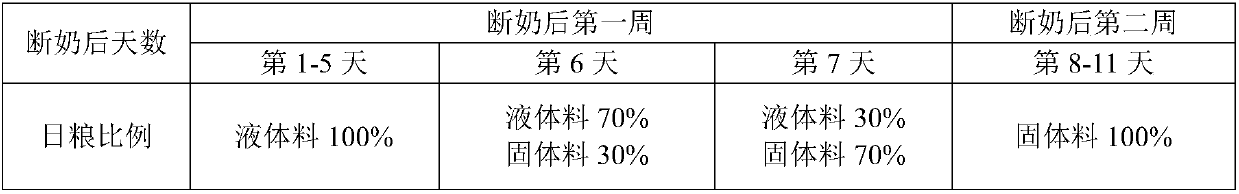

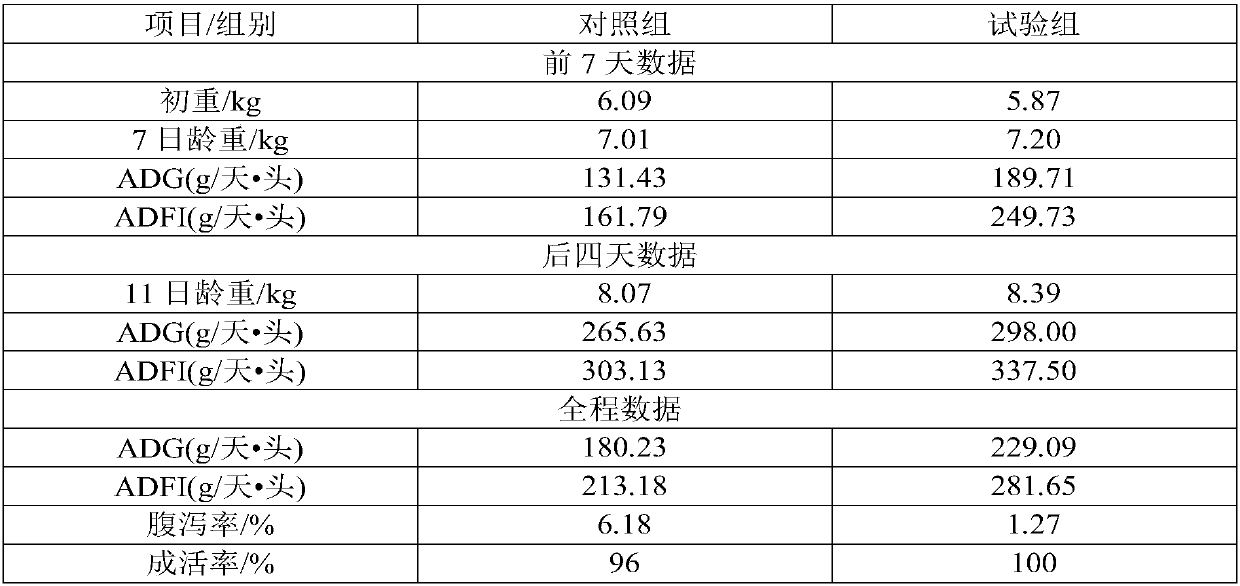

Examples

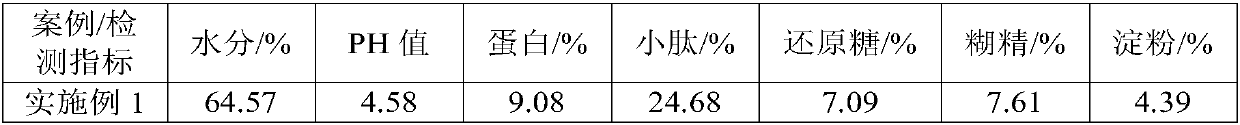

Embodiment 1

[0031] A preparation method of a liquid feed, the liquid feed is made of the following raw materials in terms of mass fraction: 40% corn (corn for suckling pigs), 15% peeled soybean meal, 10% instant soybean meal, 4% super steam fish meal, plasma protein Powder 5%, whey powder 8%, whole milk powder 6%, glucose 2%, sucrose 4%, lysine 0.5%, calcium hydrogen phosphate 0.8%, fat powder 0.5%, monosodium glutamate 0.2% and premix 4% (Here the premix adopts the premix conventionally added in the feed).

[0032] The preparation method comprises the following steps:

[0033] 1. Grinding: Grinding the large particle raw materials (here, corn and peeled soybean meal) in the feed formula, specifically, using a pulverizer to pulverize, and the pulverizing particle size is controlled at 0.5-1.5mm (here, a diameter of Φ1.0 is used). sieve plate to control particle size).

[0034] 2. Enzymolysis: Add water and high-temperature amylase (applicable temperature is 80°C-100°C) into the liquid f...

Embodiment 2

[0058] A preparation method of a liquid feed. The liquid feed is made of the following raw materials in terms of mass fraction: 36.3% corn (corn for suckling pigs), 17.5% peeled soybean meal, 8% instant soybean meal, 3% super steam fish meal, plasma protein Powder 3%, whey powder 10%, whole milk powder 12%, glucose 1%, sucrose 4%, lysine 0.5%, calcium hydrogen phosphate 1%, fat powder 1.5%, monosodium glutamate 0.2% and premix 2% (Here the premix adopts the premix conventionally added in the feed).

[0059] The preparation method comprises the following steps:

[0060] 1. Grinding: Grinding the large particle raw materials (here, corn and peeled soybean meal) in the feed formula, specifically, using a pulverizer to pulverize, and the pulverizing particle size is controlled at 0.5-1.5mm (here, Φ0.8 sieve plate to control particle size).

[0061] 2. Enzymolysis: Add water and high-temperature amylase into the liquid fermentation tank, then add the raw materials that need to be...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com