A kind of titanium-based sn-sb-ce oxide electrode and its preparation method and application

A sn-sb-ce, oxide technology, applied in the field of electrochemical catalytic oxidation anode materials, can solve the problems of short service life, too low oxygen evolution potential, and limit the wide application of electrodes, so as to improve the contact specific surface area, high analysis Oxygen potential, the effect of overcoming corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

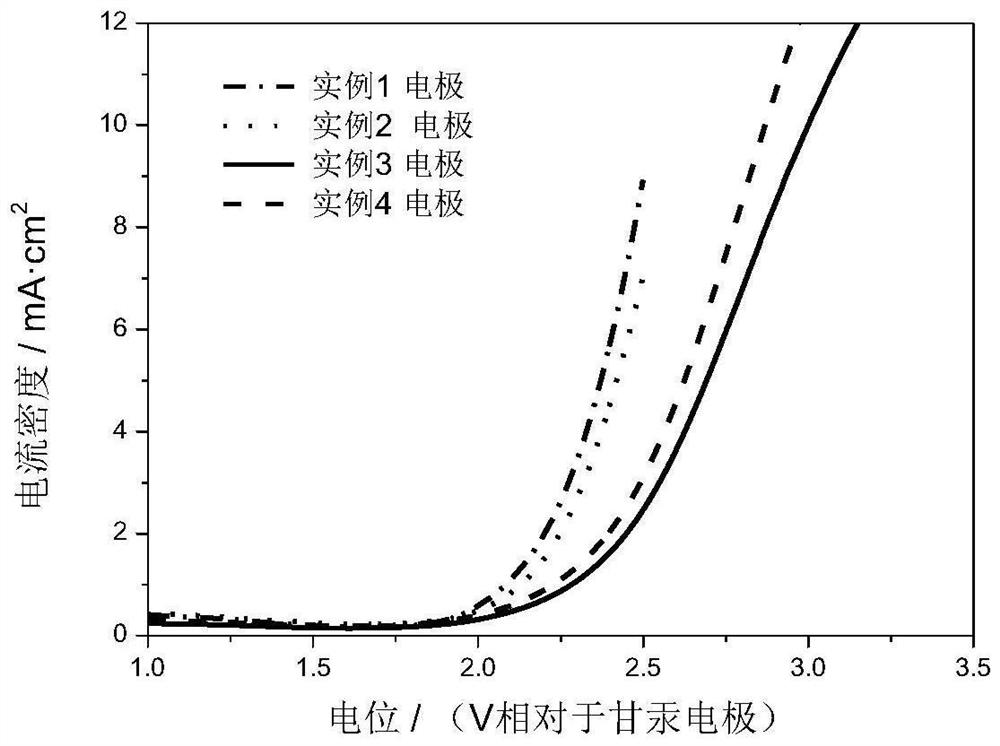

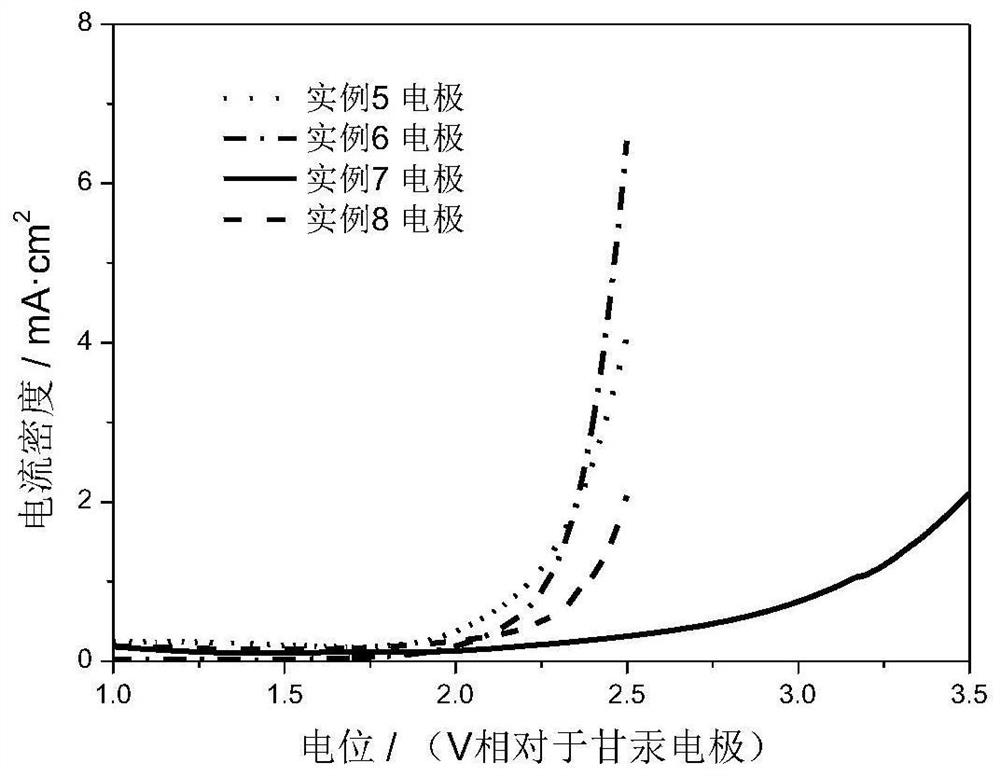

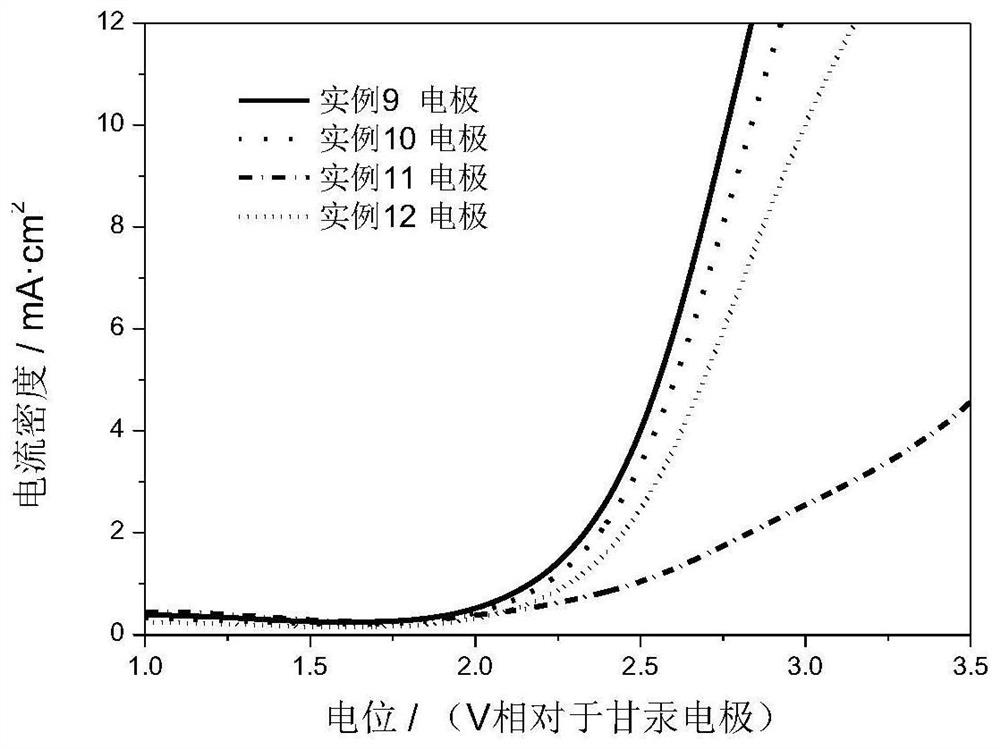

Embodiment 1

[0045] (1) The titanium plate was repeatedly polished with sandpaper, and then cleaned and etched with deionized water, alkali, and acid to obtain a pretreated titanium base; 50mmol SnCl 4 ·5H 2 O, 7mmol SbCl 3 , 0.5mmol Ce(NO 3 ) 3 ·6H 2 O, 30mmolC 6 h 12 o 6 ·H 2 O, 0.69mL HNO 3 Dissolve in deionized water to 100mL to form a homogeneous solution as the electroplating solution; immerse the pretreated titanium base (30mm*30mm, one side sealed with insulating tape) into the above electroplating solution, at 4mA / cm 2 Electroplating was carried out for 120 sec under the action of current density, and the electrode was taken out and rinsed with deionized water, dried in an oven at 80°C for 5 minutes, then quickly transferred to a muffle furnace, and calcined at 500°C for 30 minutes to obtain a titanium base after electroplating.

[0046] (2) 5mmol SnCl 4 ·5H 2 O, 0.75mmol SbCl 3 , 0.05mmol Ce(NO 3 ) 3 ·6H 2 O, 12.5mmolC 6 h 12 o 6 ·H 2 O was dissolved in a mixed...

Embodiment 2

[0049] (1) The titanium plate was repeatedly polished with sandpaper, and then cleaned and etched with deionized water, alkali, and acid to obtain a pretreated titanium base; 50mmol SnCl 4 ·5H 2 O, 7mmol SbCl 3 , 0.5mmol Ce(NO 3 ) 3 ·6H 2 O, 30mmolC 6 h 12 o 6 ·H 2 O, 0.69mL HNO 3 Dissolve in deionized water to 100mL to form a homogeneous solution as the electroplating solution; immerse the pretreated titanium base (30mm*30mm, one side sealed with insulating tape) into the above electroplating solution, at 4mA / cm 2 Electroplating was carried out for 120 sec under the action of current density. After the electrode was taken out and rinsed with deionized water, it was dried in an oven at 80°C for 5 minutes, then quickly transferred to a muffle furnace, calcined at 500°C for 30 minutes, and the electroplating and calcining operations were repeated twice to obtain Titanium base after electroplating.

[0050] (2) 5mmol SnCl 4 ·5H 2 O, 0.75mmol SbCl 3 , 0.05mmol Ce(NO ...

Embodiment 3

[0053] (1) The titanium plate was repeatedly polished with sandpaper, and then cleaned and etched with deionized water, alkali, and acid to obtain a pretreated titanium base; 50mmol SnCl 4 ·5H 2 O, 7mmol SbCl 3 , 0.5mmol Ce(NO 3 ) 3 ·6H 2 O, 30mmolC 6 h 12 o 6 ·H 2 O, 0.69mL HNO 3 Dissolve in deionized water to 100mL to form a homogeneous solution as the electroplating solution; immerse the pretreated titanium base (30mm*30mm, one side sealed with insulating tape) into the above electroplating solution, at 4mA / cm 2 Electroplating was carried out for 120 sec under the action of current density. After the electrode was taken out and rinsed with deionized water, it was dried in an oven at 80°C for 5 minutes, then quickly transferred to a muffle furnace, calcined at 500°C for 30 minutes, and the electroplating and calcining operations were repeated 3 times to obtain Titanium base after electroplating.

[0054] (2) 5mmol SnCl 4 ·5H 2 O, 0.75mmol SbCl 3 , 0.05mmol Ce(NO...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com