Pressureless sintered conductive silver paste and preparation method thereof

A technology of conductive silver paste and silver powder, which is applied in the manufacture of cables/conductors, conductive materials dispersed in non-conductive inorganic materials, circuits, etc., can solve the problems of non-intensive diffusion and achieve reduced hard agglomeration and high bonding characteristics , Improve the effect of compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A. Weigh 1.0g potassium iodate and dissolve it in 20mL deionized water. Weigh 5.0 g of micron silver powder with a size of 2 μm in 50 mL of absolute ethanol and ultrasonicate for 10 min. The dissolved potassium iodate solution and the dispersed micron silver powder are mixed, magnetically stirred at room temperature for 60 minutes, and centrifuged and washed several times.

[0028] B. Preparation of bonding carrier: Weigh 2.0g of absolute ethanol, 0.02g of polyvinylpyrrolidone, and 0.01g of hydroxypropylmethylcellulose in a mixing tank, and mix them thoroughly with a mixer at 2000rpm to form a A bonding carrier with a certain viscosity.

[0029] C. Add the surface-modified silver powder to the bonding carrier, mix it with a blender at 2000 rpm, and then weigh 5.0 g of 300nm nano silver particles and the bonding carrier, and use the blender to Mixing at a speed of 2000rpm can obtain a pressureless sintered conductive silver paste.

Embodiment 2

[0031] A. Weigh 1.0g potassium perchlorate and dissolve it in 20mL deionized water. Weigh 5.0 g of silver powder with a size of 1 μm in 50 mL of absolute ethanol and ultrasonicate for 10 minutes. The dissolved potassium iodate solution and the dispersed micron silver powder are mixed, magnetically stirred at room temperature for 60 minutes, and centrifuged and washed several times.

[0032] B. Preparation of bonding carrier: Weigh 2.0g of ethylene glycol monomethyl ether, 0.02g of polyvinylpyrrolidone, and 0.01g of terpineol in a mixing tank, and mix them thoroughly with a mixer at 2000rpm to form a A bonding carrier with a certain viscosity.

[0033] C. Add the surface-modified silver powder to the bonding carrier, mix it with a blender at 2000 rpm, and then weigh 5.0 g of 100nm nano silver particles and the bonding carrier, and use the blender to Mixing at a speed of 2000rpm can obtain a pressureless sintered conductive silver paste.

Embodiment 3

[0035] A. Weigh 1.0g potassium perchlorate and dissolve it in 20mL deionized water. Weigh 5.0 g of silver powder with a size of 3 μm in 50 mL of absolute ethanol and ultrasonicate for 10 minutes. The dissolved potassium iodate solution and the dispersed micron silver powder are mixed, magnetically stirred at room temperature for 60 minutes, and centrifuged and washed several times.

[0036] B. Preparation of bonding carrier: Weigh 2.0 g of diethylene glycol monobutyl ether acetate and 0.01 g of terpineol in a mixing tank, and mix thoroughly with a mixer at 2000 rpm to form a certain viscosity Bonded carrier.

[0037] C. Add the surface-modified silver powder to the bonding carrier and mix it with a mixer at a speed of 2000 rpm to obtain a pressureless sintered micron silver paste.

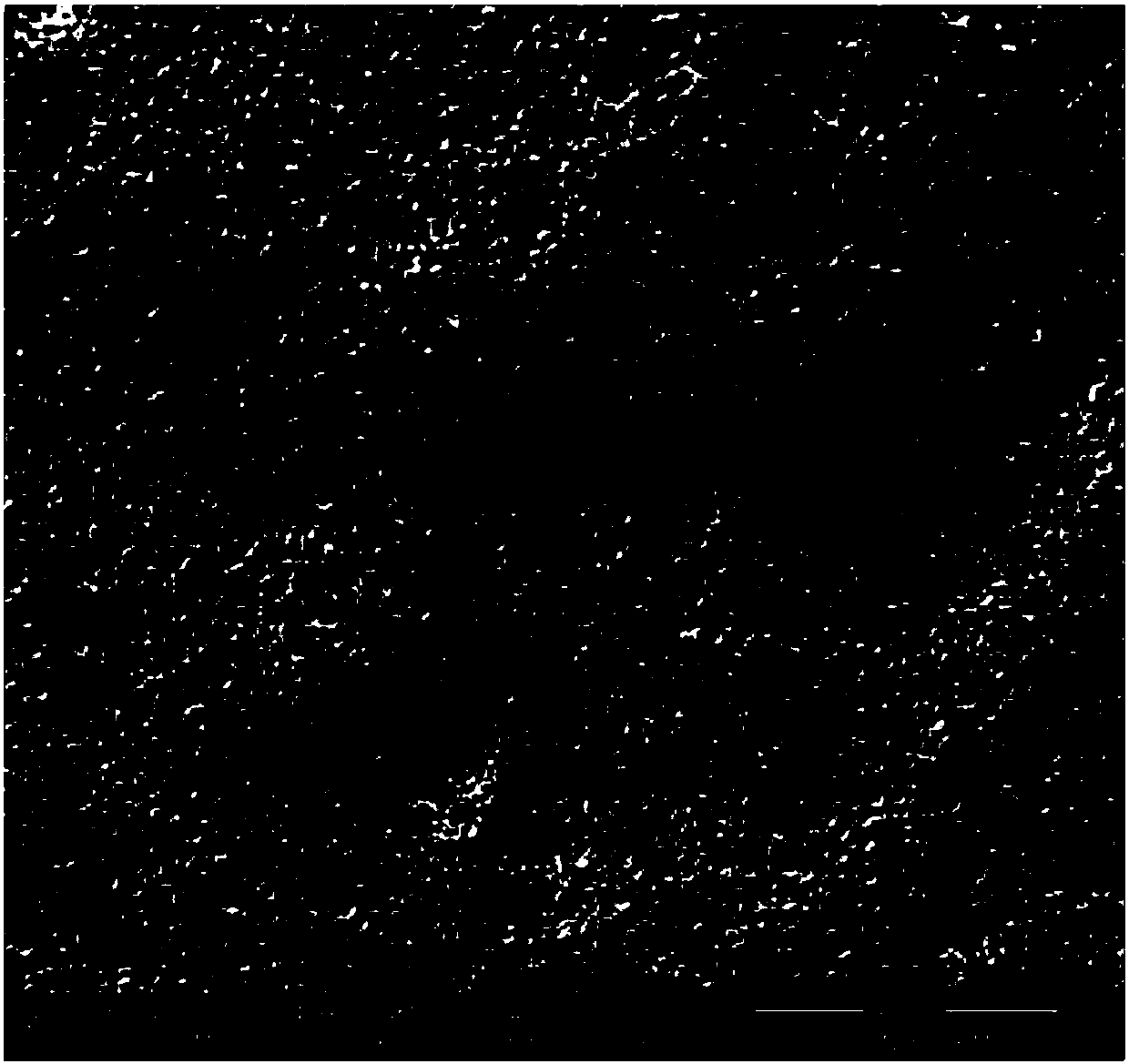

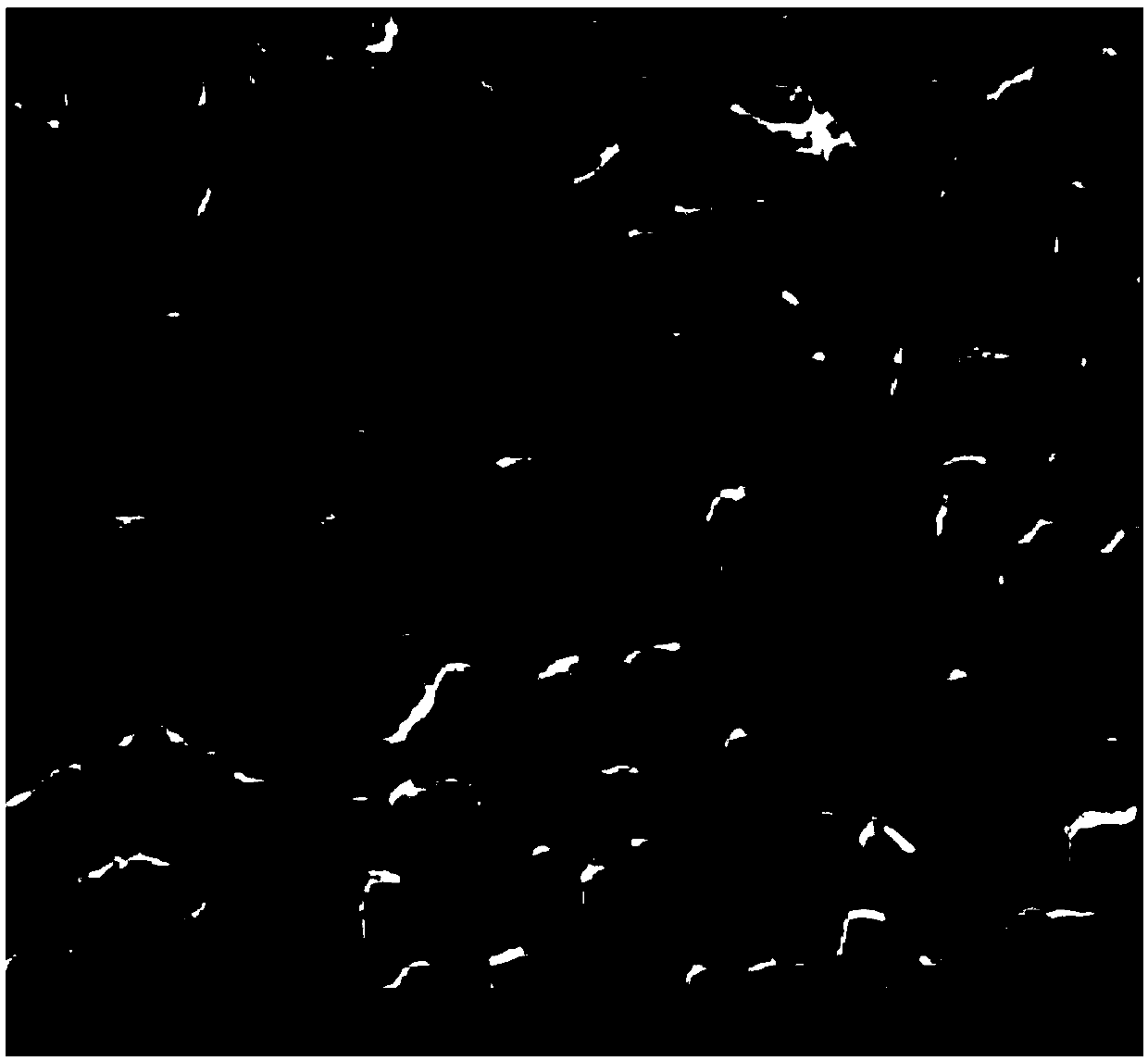

[0038] by Figure 1~Figure 9 By comparison, it can be found that the conductive silver paste obtained according to Examples 1, 2 and 3 of the present invention has better sintering performance under no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com