Rare-earth-doped lithium manganese silicate positive electrode material and microwave-assisted preparation method thereof

A technology of lithium manganese silicate and positive electrode materials, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve problems such as low reaction efficiency, uneven distribution of doping components, and poor wave absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

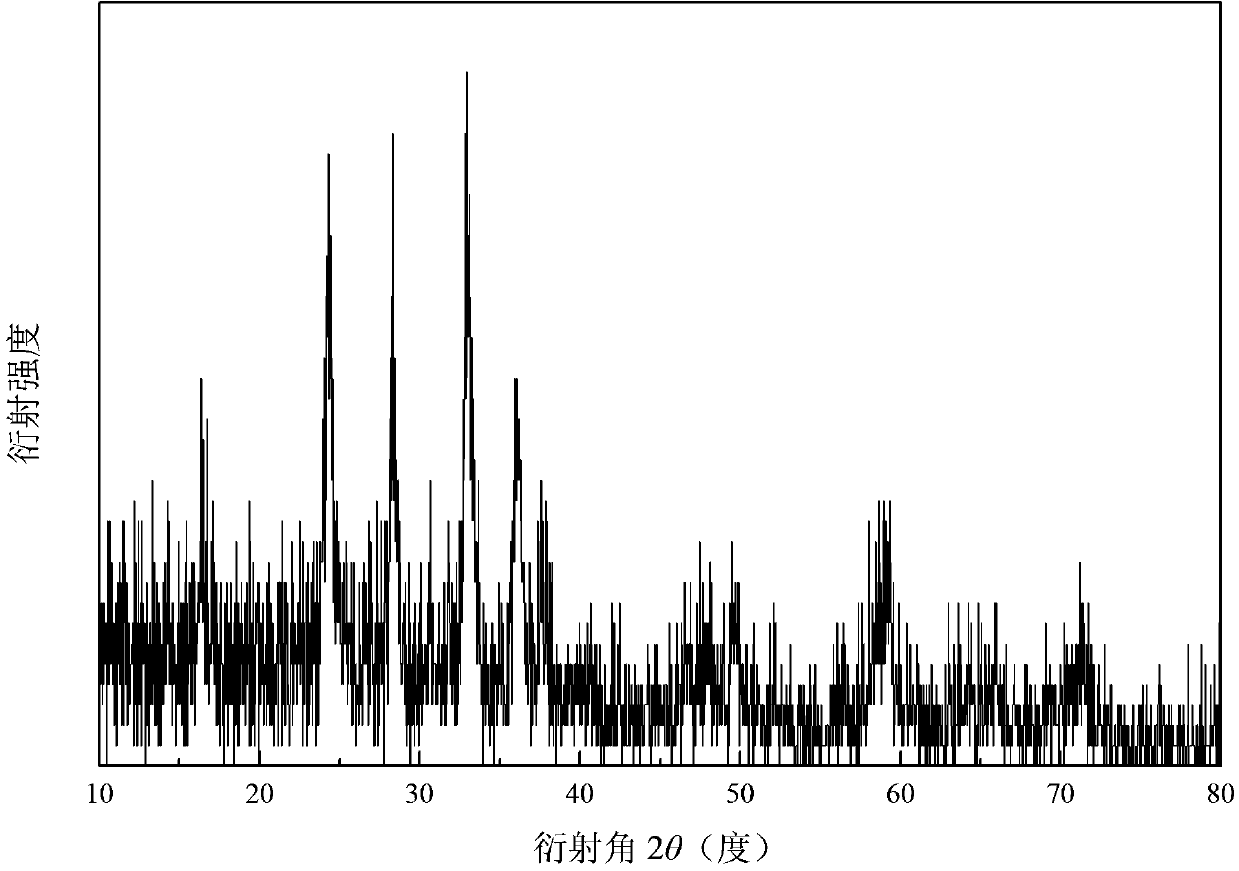

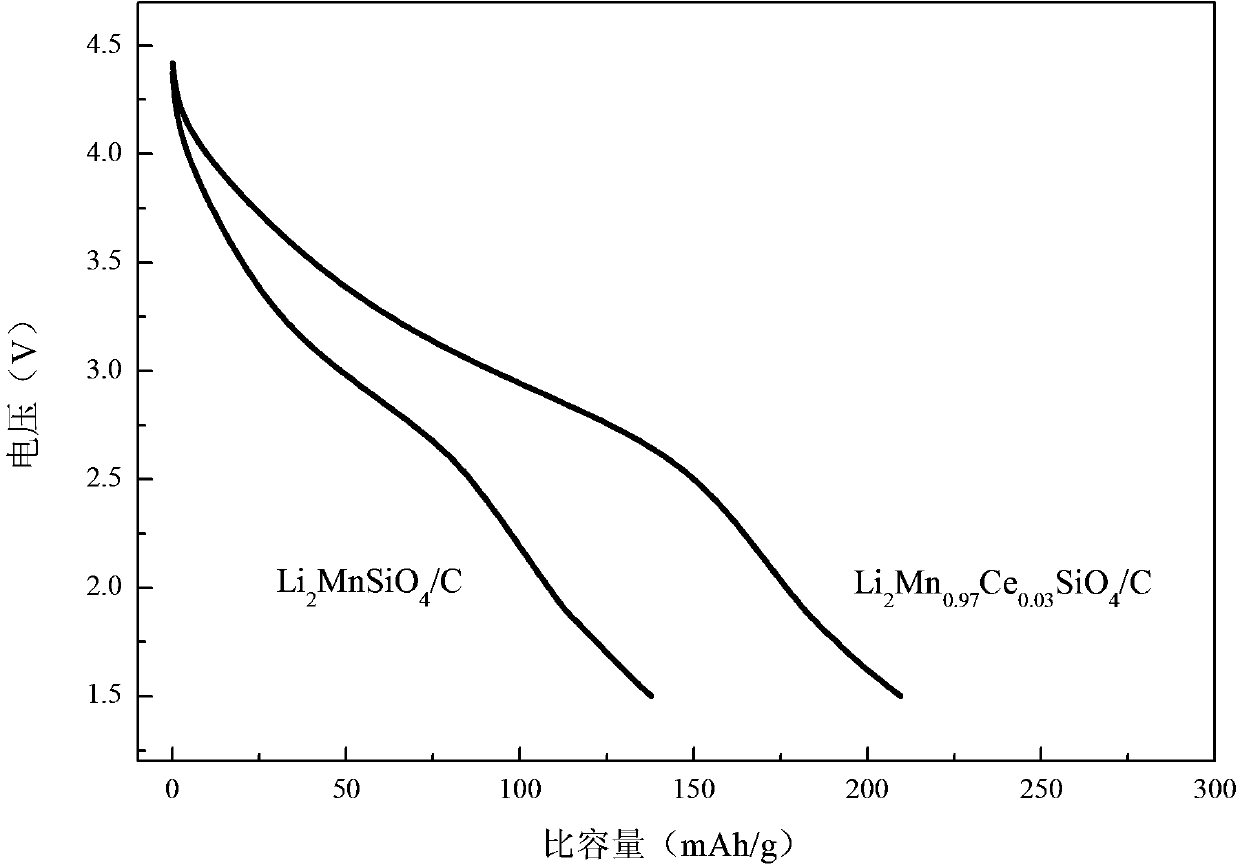

Embodiment 1

[0033] Lithium acetate, manganese acetate, methyl orthosilicate, a certain amount of citric acid (accounting for 25% of the total mass) and rare earth compound lanthanum nitrate according to the ratio of Li: Mn: Si: La material amount is 2.02:0.99:1 : 0.01 was added to an appropriate amount of dispersant (80ml distilled water, 20ml ethanol) to mix and disperse, then 12ml ammonia water with a mass fraction of 20% was added dropwise as a catalyst, heated and stirred at 80°C for 8h, and then evaporated to dryness in a water bath and solvent ground to obtain lanthanum doped Lithium manganese silicate material precursor. Afterwards, the precursor was transferred to a microwave field, and the temperature was raised to 650 °C at a heating rate of 20 °C / min. Under the protection of a 10% hydrogen / 90% argon mixed atmosphere, microwave heat treatment was performed for 150 min, and then rapidly cooled to room temperature to obtain Product Li 2 mn 0.99 La 0.01 SiO 4 / C material. Depe...

Embodiment 2

[0035] Lithium nitrate, manganese dioxide, silicon dioxide, a certain amount of phenolic resin (accounting for 30% of the total mass), and rare earth compounds neodymium nitrate and lanthanum nitrate according to the ratio of Li: Mn: Si: Nd: La to 2.02 :0.94:1:0.03:0.03 After mixing evenly, add it to a ball mill jar, mill it in a planetary ball mill at a speed of 200r / min for 2 hours, make it fully mixed, and dry to obtain a precursor of neodymium-lanthanum doped manganese lithium silicate material . Afterwards, the precursor was transferred to a microwave field, and the temperature was raised to 670 °C at a heating rate of 15 °C / min. Under the protection of an argon atmosphere, microwave heat treatment was performed for 150 min, and the product Li was obtained after cooling down with the furnace. 2 mn 0.94 Nd 0.03 La 0.03 SiO 4 / C material.

Embodiment 3

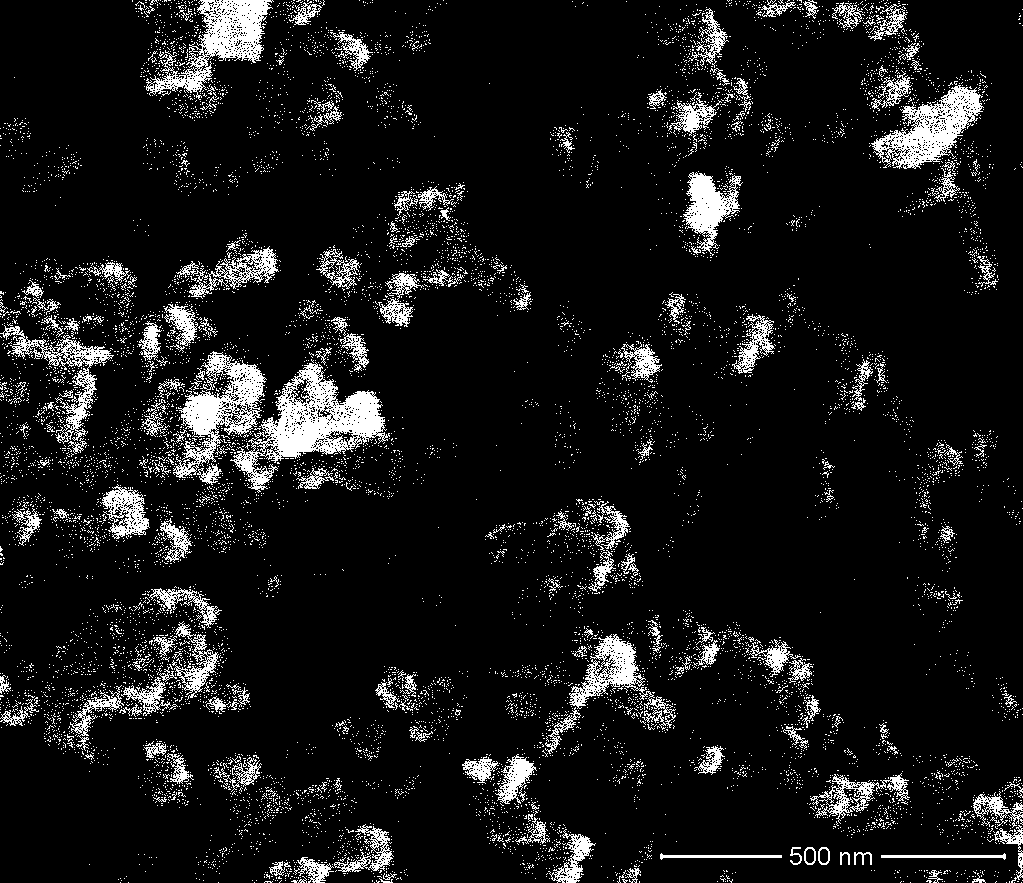

[0037] Lithium acetate, manganese acetate, ethyl orthosilicate, a certain amount of ascorbic acid (accounting for 35% of the total mass) and rare earth compound cerium nitrate according to the ratio of Li:Mn:Si:Ce is 2.03:0.97:1: Add 0.03 to an appropriate amount of dispersant (100ml of water, 25ml of ethanol) to mix and disperse, then add 10ml of ammonia water with a mass fraction of 25% dropwise as a catalyst, heat and stir at 70°C for 10h, then evaporate to dryness in a water bath and grind the solvent to obtain cerium-doped silicon Manganese oxide lithium material precursor. Afterwards, the precursor was transferred to a microwave field, and the temperature was raised to 680 °C at a heating rate of 20 °C / min. Under the protection of a mixed atmosphere of 5% hydrogen / 95% argon, microwave heat treatment was performed for 100 min, and the cooling rate was 10 °C / min. Slowly down to room temperature, the product Li 2 mn 0.97 Ce 0.03 SiO 4 / C material, using the product as t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com