Film electrode and manufacturing method thereof and application

A thin-film electrode and manufacturing method technology, applied in cable/conductor manufacturing, circuits, conductive materials, etc., can solve the problems of material waste in spin coating process, inability to achieve continuous mass production, etc., and achieve low cost, excellent flexibility, Material saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

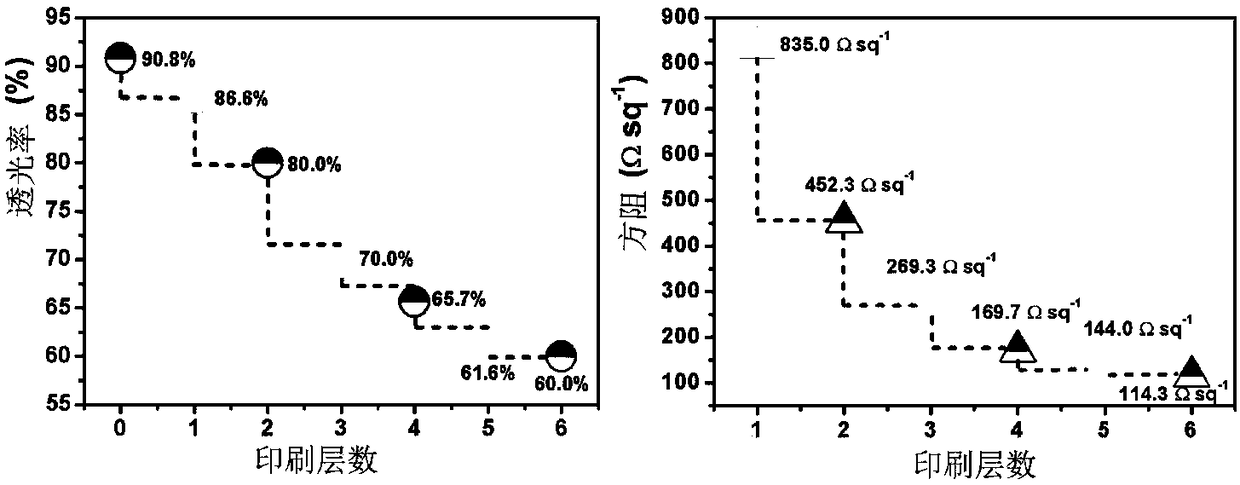

[0025] The polyethylene terephthalate PET substrate was plasma-treated for 10 s and fixed on a screen printing platform. Select a screen mesh number of 300-400 mesh, a film thickness of 6-12 μm, a screen material of stainless steel mesh, and a screen wire diameter of 16-30 μm, and print 1 layer to 6 layers on the treated polyethylene terephthalate substrate. layer of conductive polymer PEDOT-PSS hexagonal mesh. The control grid line width is 50 μm, and the period is 100 μm. Place in a vacuum oven and anneal at 120°C for 30min. figure 1 It can be seen from the figure that as the number of printing layers increases, the square resistance of the flexible electrode decreases, but the light transmittance also decreases, and the optimal number of printing layers is 2 layers.

Embodiment 2

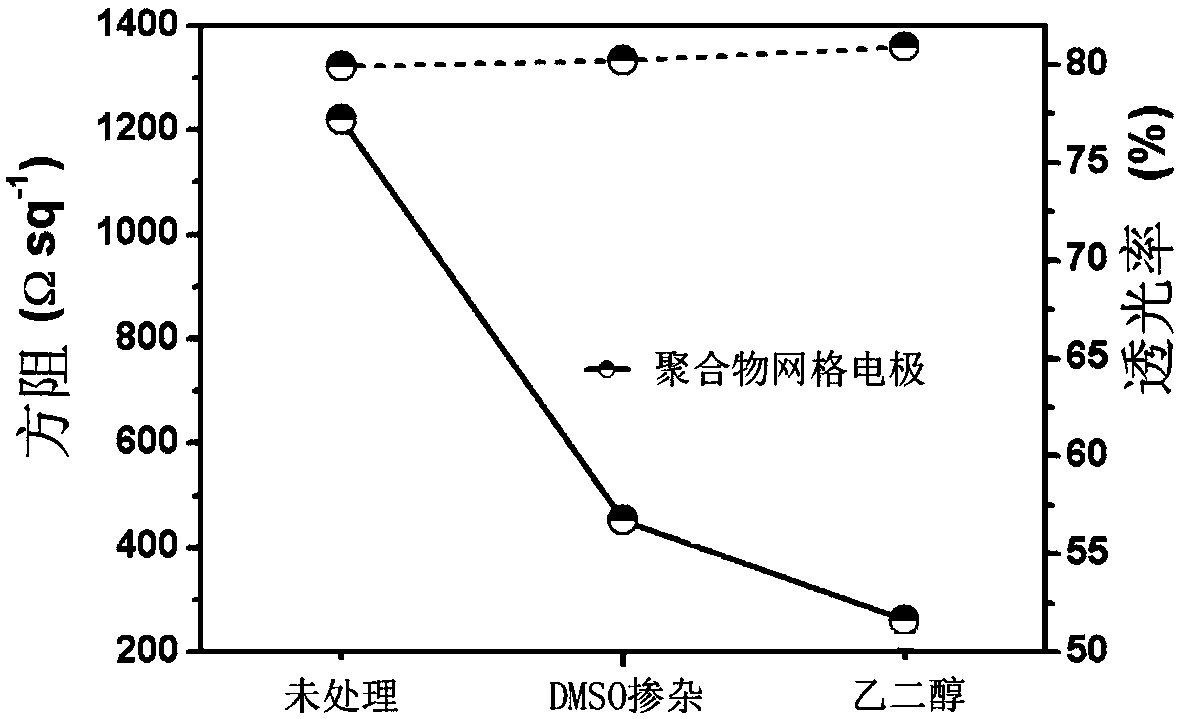

[0027]The polyethylene terephthalate PET substrate was plasma-treated for 10 s and fixed on a screen printing platform. Added 5% dimethylsulfoxide to PEDOT-PSS ink, and stirred it mechanically for 30min. Select a screen mesh number of 300-400 mesh, a film thickness of 6-12 μm, a screen material of stainless steel mesh, and a screen wire diameter of 16-30 μm, and print 2 layers of conductive film on the treated polyethylene terephthalate substrate. Polymer PEDOT / PSS hexagonal mesh. The control grid line width is 50 μm, and the period is 100 μm. Soak in ethylene glycol for 30 minutes, then place in a vacuum oven and anneal at 120°C for 30 minutes. figure 2 It can be seen from the figure that the doping and immersion of the high boiling point solvent has little effect on the light transmittance of the flexible electrode, but effectively reduces the square resistance of the electrode.

Embodiment 3

[0029] The polyethylene terephthalate PET substrate was plasma-treated for 10 s and fixed on a screen printing platform. Added 5% dimethylsulfoxide to PEDOT / SS ink, and stirred it mechanically for 30min. Select a screen mesh number of 300-400 mesh, a film thickness of 6-12 μm, a screen material of stainless steel mesh, and a screen wire diameter of 16-30 μm, and print 2 layers of conductive film on the treated polyethylene terephthalate substrate. Polymer PEDOT:PSS hexagonal mesh. The control grid line width is 50 μm, and the period is 100 μm. Soak in ethylene glycol for 30 minutes, then place in a vacuum oven and anneal at 120°C for 30 minutes. The fabricated hexagonal conductive polymer grid electrodes are shown under the microscope as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com