Preparation method of thin-layer metal lithium-based negative electrode

A metal lithium and negative electrode technology, which is applied in the field of preparation of thin-layer metal lithium-based negative electrodes, can solve the problems of puncturing the diaphragm, producing lithium dendrites, explosion, etc., and achieves the effect of uniform deposition, uniform deposition, and easier deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

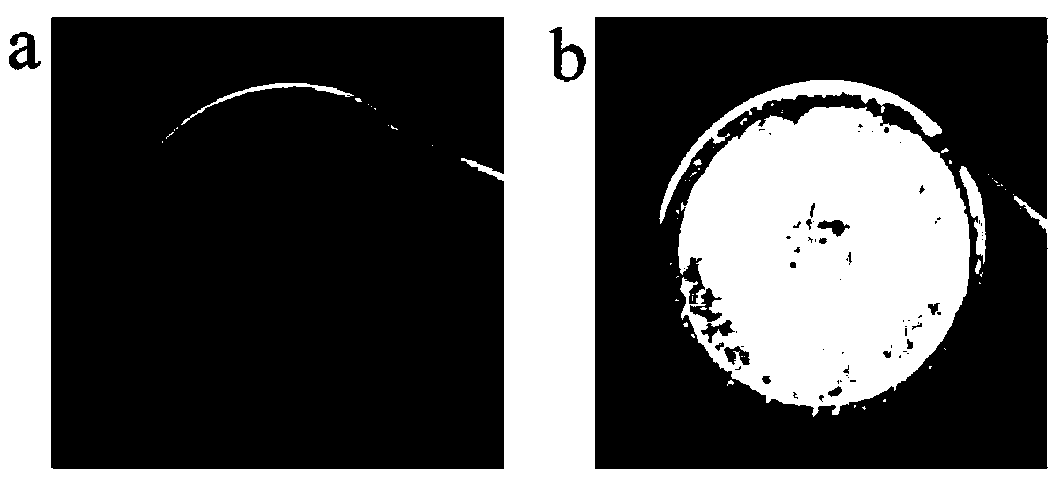

[0019] figure 1 Comparison of disassembled pictures after lithium electrodeposition on the surface of copper foil with / without graphene: (a) little and uneven white metal lithium deposition on the surface of copper foil without graphene; (b) white metal lithium deposition on the surface of graphene / copper foil Large and even.

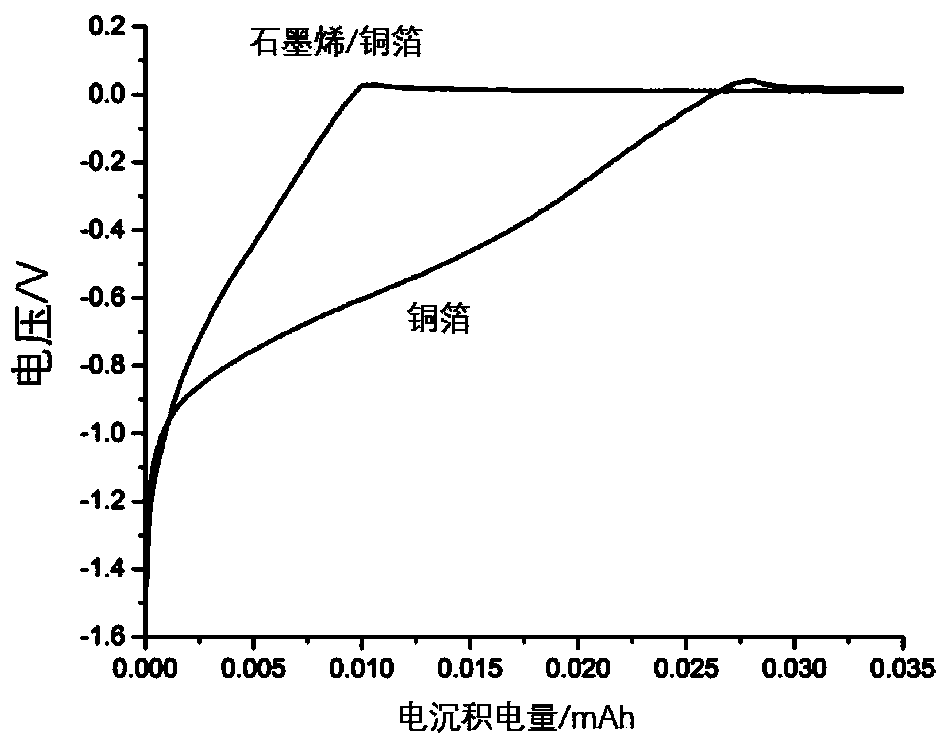

[0020] figure 2 Comparison of voltage curves during lithium electrodeposition on the surface of copper foil with / without graphene: the voltage curve of graphene / copper foil rises more smoothly and stably, and has a lower overpotential, indicating that electrodeposited lithium is more uniform and stable

[0021] Cut the copper foil into a suitable size and put it into a quartz tube, heat it up to around 1000°C with a tube furnace in a mixed atmosphere of argon and hydrogen, then feed methane gas to grow graphene, and turn off the methane gas after 30 minutes. Start to cool down to obtain copper foil with graphene film.

[0022] Then assemble the ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com