A photocatalytic reaction device

A photocatalytic reaction and reactor technology, which is applied in chemical instruments and methods, chemical/physical processes, oxidized water/sewage treatment, etc., can solve the problem of slow catalyst surface mass transfer efficiency, difficult catalyst recovery, limited separation rate, etc. To achieve the effect of enhancing the ability of ultraviolet photooxidation, promoting the ultraviolet photooxidation reaction, and expanding the scope of treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

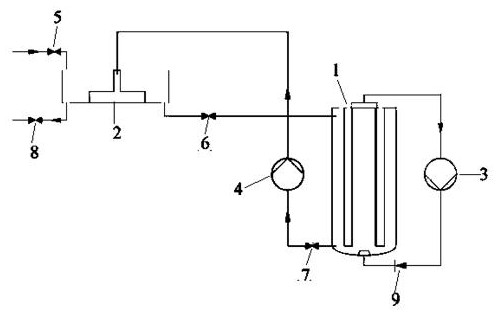

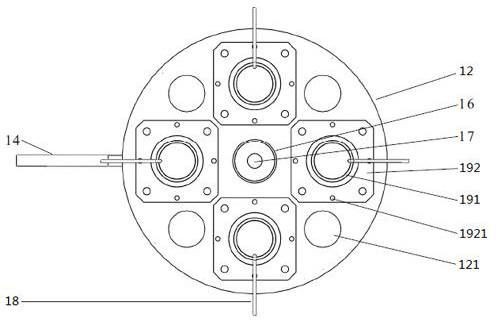

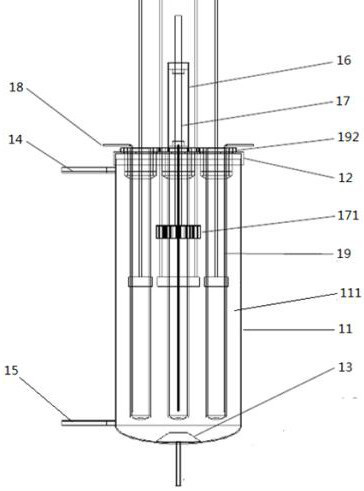

[0031] Such as Figure 1-5 As shown, when the present invention is not in use, the first valve 5, the second valve 6, the third valve 7 and the fourth valve 8 are all in closed state, and the electric control disk 23, the air pump 3 and the water pump 4 are not started. During use, a catalyst is placed in the water tank 21, and then the first valve 5 is opened to allow the untreated primary waste water to enter the water tank 21 of the magnetic separator 2. After the primary waste water enters the water tank 21, the mechanical stirrer and the ultrasonic system are started, and the Under the combined action of the agitator and the ultrasonic system, the magnetic catalyst can be effectively dispersed and suspended in the primary wastewater, so that the primary wastewater is mixed with the catalyst.

[0032] Then open the second valve 6, so that the primary waste water mixed with the catalyst enters the still body 11 and the kettle cover 12 to form the accommodation chamber 111 a...

Embodiment 2

[0042] With reference to the settings in Example 1, only the gas flow rate in the air pump 3 was changed to 4L / min, and the ozone concentration generated was 78ppm. Finally, the COD concentration in the tertiary wastewater was measured to be 14mg / L, and the COD removal rate was 93%.

Embodiment 3

[0044] Referring to the settings in Example 1, only the gas flow rate in the air pump 3 was changed to 2L / min, and the generated ozone concentration was 53ppm. Finally, the COD concentration in the tertiary wastewater was measured to be 37mg / L, and the COD removal rate was 82%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com