Microcapsule feed for larval and juvenile spotted maigre and preparation method thereof

A technology of larvae and juveniles and microcapsules, which is applied in the field of microencapsulated feed and preparation of yellow croaker larvae and juveniles, to achieve the effects of increasing absorption efficiency, improving thermal effect, and increasing retention time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

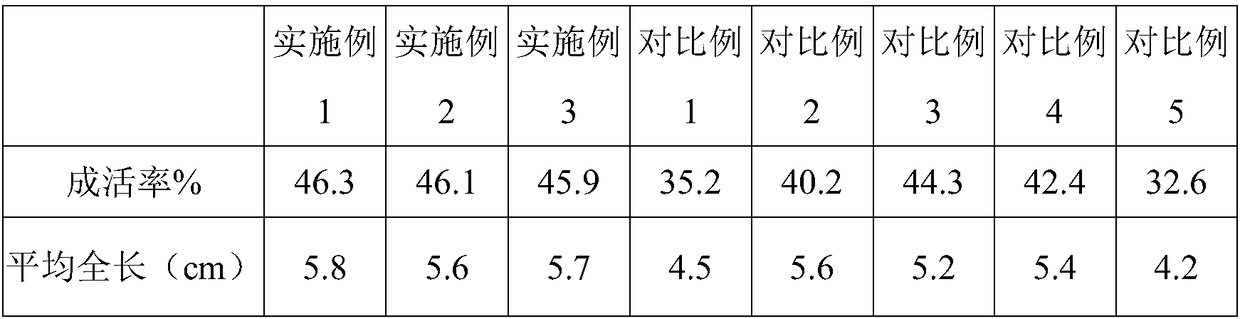

Examples

preparation example Construction

[0029] The preparation method of above-mentioned yellow croaker juvenile microcapsule feed comprises the following steps:

[0030] (1) Grinding the solid raw materials and additives with an ultrafine pulverizer (WFJ series ultrafine pulverizer, Jiangyin Jinke Pulverizer Machinery Co., Ltd.), the particle size is less than 20 μm;

[0031] (2) Weigh all kinds of feed materials according to the proportion, mix them according to the principle of superimposing a small amount, add a certain proportion of water, mix them fully by hand first, pass them all through a 100-mesh sieve, and then use a three-dimensional multi-directional motion mixer (YH series three-dimensional Multi-directional motion mixer, Changzhou Pu Naier Drying Equipment Co., Ltd.) mixed for 10min;

[0032] (3) Make the mixed raw materials into granules, and use one of the following three methods to make granules: a. Make the mixed raw materials into granules by fluidized bed top spraying method, including the follo...

Embodiment 1

[0038] A kind of microencapsulated feed for juvenile yellow croaker larvae, in units of parts by mass, comprising the following raw materials: white fish meal (crude protein is 67%; crude fat 9% (dry weight), American Seafood Company), 40 parts by mass; phosphorus Shrimp powder (crude protein is 63.9%; crude fat is 5.6% (dry weight), Zhoushan Fengshun Fish Meal Products Co., Ltd.), 15 parts by mass; squid powder (crude protein is 50.3%; crude fat is 4.9% (dry weight) ), China Aquatic Zhoushan Marine Fishery Company Fish Meal Factory), 10 parts by mass; fish hydrolyzed protein (crude protein is 64.3%, crude fat is 7.6% (dry weight), self-made, adopts trypsin and papain to hydrolyze white fish meal to make) 5 parts by mass; feed yeast, 6 parts by mass; α-starch, 7.9 parts by mass; soybean lecithin, 5 parts by mass; papain, 2 parts by mass; sodium alginate, 1 part by mass; fish oil, 3 parts by mass; multivitamins , 2 parts by mass; complex minerals, 2 parts by mass, taurine, 1 pa...

Embodiment 2

[0048] A kind of microencapsulated feed for juvenile yellow croaker larvae, with parts by mass as the unit, comprising the following raw materials: white fish meal (crude protein is 67%; crude fat 9% (dry weight), American Seafood Company) 35 parts by mass, krill Powder (crude protein is 63.9%; Crude fat is 5.6% (dry weight), Zhoushan Fengshun Fish Meal Products Co., Ltd.) 18 mass parts, squid meal (crude protein is 50.3%; Crude fat is 4.9% (dry weight), China Aquatic Products (Zhoushan Ocean Fishery Company Fish Meal Factory) 8 parts by mass, fish hydrolyzed protein (crude protein is 64.3%, crude fat is 7.6% (dry weight), self-made, adopts trypsin and papain to hydrolyze white fish meal to make) 6 parts by mass , 5 parts by mass of feed yeast, 8 parts by mass of α-starch, 4 parts by mass of soybean lecithin, 2.5 parts by mass of papain, 2 parts by mass of fish oil, 2.5 parts by mass of multivitamins, 1.5 parts by mass of complex minerals, and 1.2 parts by mass of sodium algina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com