A kind of production method of tin-nickel powder

A production method, tin-nickel plating technology, applied in the field of metal powder materials, can solve the problems of lack of nickel powder coating powder, lack of tin-nickel powder, etc., and achieve the effect of convenient operation and simplified process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

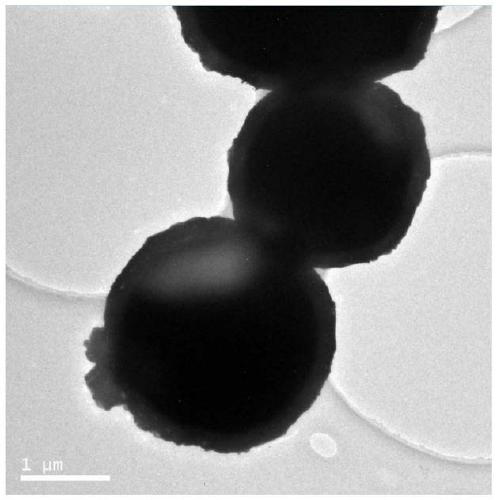

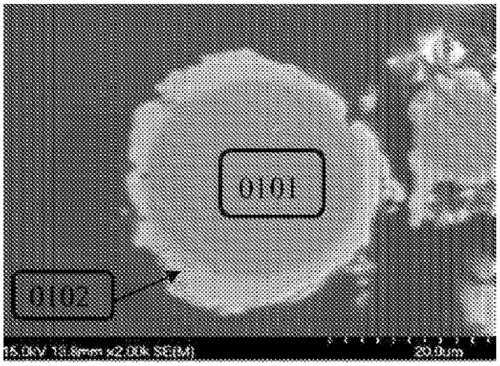

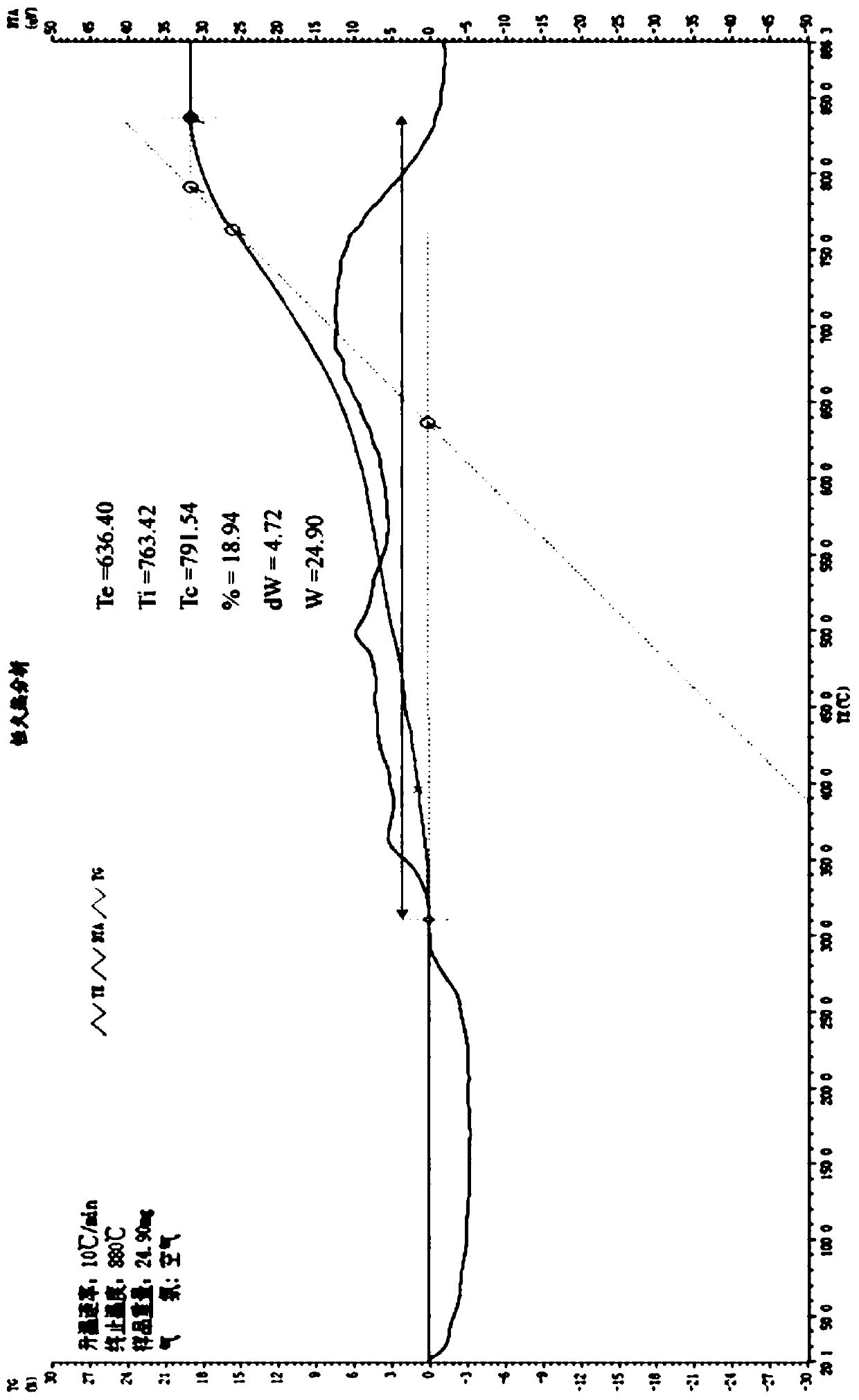

Image

Examples

Embodiment 1

[0047] A production method of tin-plated nickel powder, comprising the following steps:

[0048] 1) Nickel powder cleaning: Weigh 300ml of water, 24g of citric acid, 1.5g of OP-10, and configure 8% citric acid solution; take 10.5 grams of nickel powder, add it to the citric acid solution, and mechanically After stirring for 30 minutes, turn off the ultrasonic wave and continue stirring for 10 minutes, then wash with deionized water until the pH of the supernatant is 7 (normal temperature), and filter the water for later use;

[0049] 2) Preparation of tin salt solution: Weigh 15.6g of stannous sulfate and dissolve it in 156ml of deionized water to obtain solution a; weigh 25g of disodium edetate and dissolve it in 3L of deionized water to obtain solution b; Take 7.5g of polyvinylpyrrolidone and fully dissolve it with 400ml of alcohol to obtain solution c; mix solutions a, b and c evenly to obtain a tin salt stock solution;

[0050] 3) Preparation of the reaction stock solutio...

Embodiment 2

[0054] A production method of tin-plated nickel powder, comprising the following steps:

[0055] 1) Nickel powder cleaning: Weigh 300ml of water, 24g of tartaric acid, 1.5g of detergent-6503 to configure 8% tartaric acid solution; take 10.5 grams of nickel powder, add it to 8% tartaric acid solution, and place it in an ultrasonic disperser at 40°C After mechanically stirring for 30 minutes, turn off the ultrasonic wave and continue stirring for 10 minutes, then wash with deionized water until the pH of the supernatant is 7 (normal temperature), and filter off the water for later use;

[0056] 2) Preparation of tin salt solution: Weigh 15.6g stannous sulfate and dissolve it in 156ml deionized water to obtain solution a; weigh 25g sulfosalicylic acid and dissolve it in 3L deionized water to obtain solution b; then weigh 7.5g Fully dissolve polyvinylpyrrolidone with 400ml of alcohol to obtain solution c; mix solutions a, b, and c evenly to obtain a tin salt stock solution;

[00...

Embodiment 3

[0061] A production method of tin-plated nickel powder, comprising the following steps:

[0062] 1) Cleaning of nickel powder: Weigh 300ml of water, 24g of malic acid, and 1.5g of fatty alcohol polyoxyethylene ether to configure 8% malic acid solution; take 10.5 grams of nickel powder, add it to 8% of malic acid solution, and heat it under ultrasonic at 40°C After 30 minutes of mechanical stirring in the disperser, turn off the ultrasonic wave and continue to stir for 10 minutes, then wash with deionized water until the pH of the supernatant is 7 (normal temperature), filter off the water and set aside;

[0063] 2) Preparation of tin salt solution: Weigh 15.6g stannous sulfate and dissolve it in 156ml deionized water to obtain solution a; weigh 25g ethylenediamine and dissolve it in 3L deionized water to obtain solution b; then weigh 7.5g polyethylene Dissolve pyrrolidone in 400ml of alcohol to obtain solution c; mix solutions a, b and c evenly to obtain tin salt stock solutio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com