Preparation method for nanometer silicon powder

A technology of nano-silicon powder and nano-silicon, which is applied in the field of material chemistry, can solve problems such as uneven particle distribution, long time consumption, and great impact on product quality, and achieve the effects of ensuring product quality, reducing production costs, and regular crystal lattices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

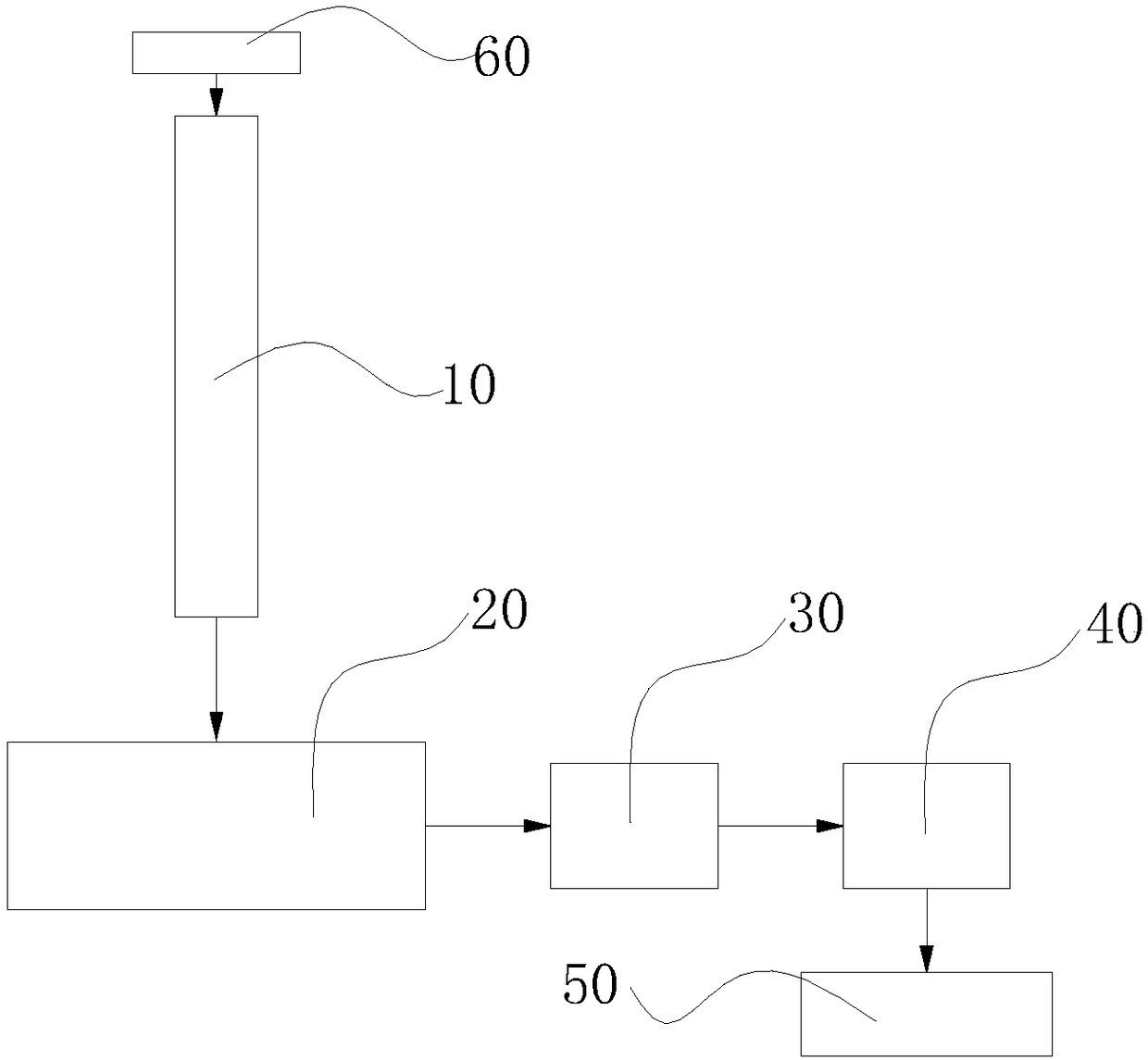

[0019] Embodiment 1: the preparation of nano silicon powder

[0020] (1) Vacuumize the entire preparation system, and add nitrogen at the same time for flushing and protection until the entire preparation system is a nitrogen environment;

[0021] (2) Start the plasma generator 10, adjust to the working gas pressure is 0.3MPa, the working voltage is 300V, the working current is 300A, and the working flow is 70m 3 / h;

[0022] (3) Use silane with a purity of 99.99% as a raw material, start the flowmeter 60, and make the raw material pass through the plasma arc and enter the plasma generator 10 at a feed rate of 5 kg / h. Under the action of the plasma, silane is rapidly ionized and decomposed to form Silicon ions and hydrogen ions, and silicon ions recombine to nucleate to form nano-silicon particles;

[0023] (4) Driven by the nitrogen flow, the nano-silicon particles enter the separator for gas-solid separation, and the separated gas is emptied or recycled after passing throu...

Embodiment 2

[0029] Embodiment 2: the preparation of nano silicon powder

[0030] Prepare according to the preparation method of Example 1, the difference is that the working gas pressure of the plasma generator 10 in the step (2) is 0.4MPa, the working voltage is 300V, the working current is 350A, and the working flow is 75m 3 / h; the feed rate of the raw material silane in the step (3) is 7kg / h; the time for the plasma generator 10 to continue running in the step (5) is 70 minutes.

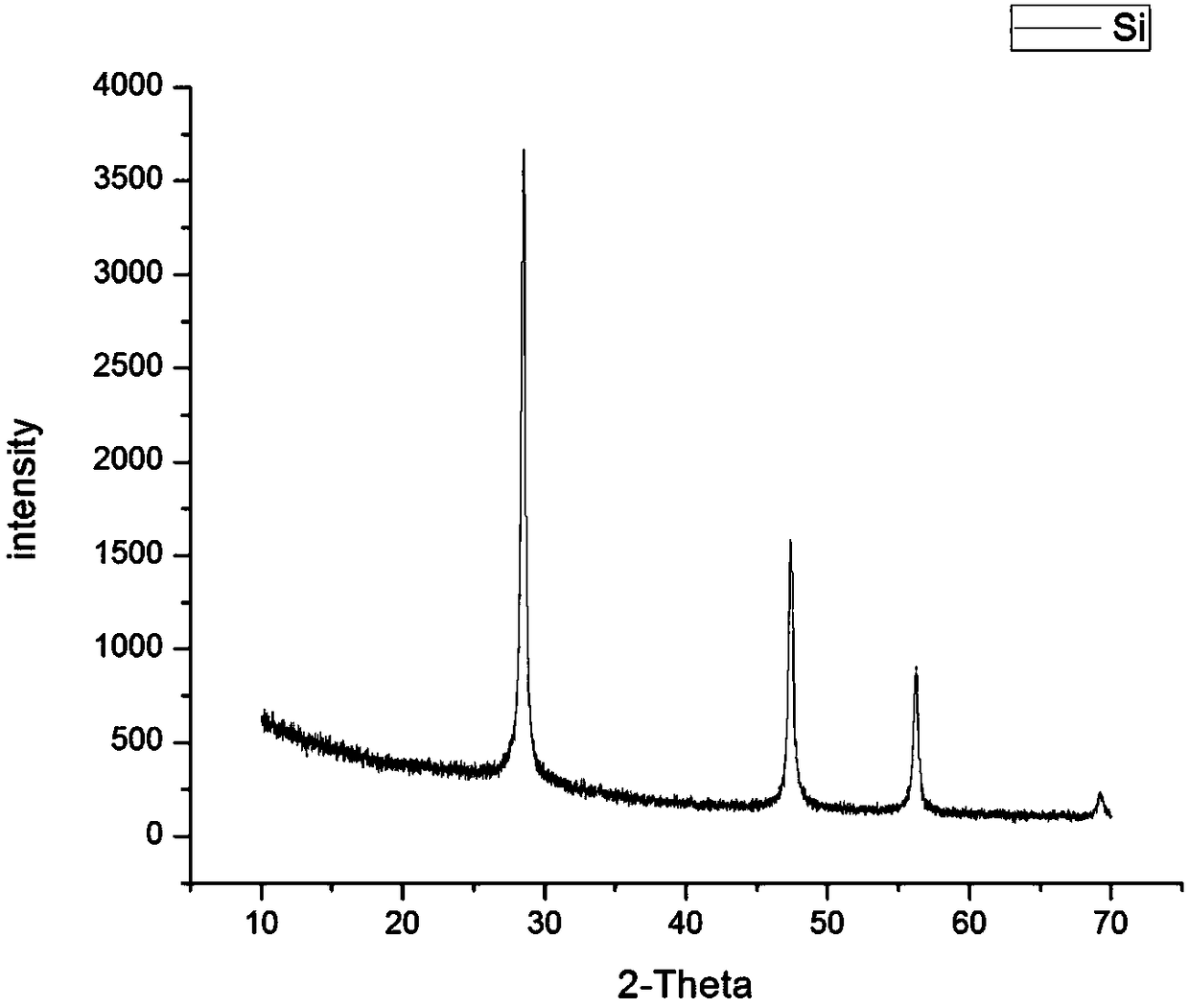

[0031] The nano-silicon powder obtained in the present embodiment is a brownish-yellow powder, and through X-ray diffraction analysis, the XDR figure is as follows Figure 4 As shown, its test values are shown in Table 2:

[0032] Table 2:

[0033] 2-Theta

[0034] Scanning electron microscopy, such as Figure 5 As shown, the average particle size is 84nm, and the specific surface area is 78.1m 2 / g.

Embodiment 3

[0035] Embodiment 3: the preparation of nano silicon powder

[0036] Prepare according to the preparation method of Example 1, the difference is that the working gas pressure of the plasma generator 10 in the step (2) is 0.5MPa, the working voltage is 350V, the working current is 350A, and the working flow is 80m 3 / h; the feed rate of the raw material silane in the step (3) is 10kg / h; the time for the plasma generator 10 to continue running in the step (5) is 90 minutes.

[0037] The nano-silicon powder obtained in the present embodiment is a brownish-yellow powder, and through X-ray diffraction analysis, the XDR figure is as follows Image 6 As shown, its test values are shown in Table 3:

[0038] table 3:

[0039] 2-Theta

[0040] Scanning electron microscopy, such as Figure 7 As shown, the average particle size is 93nm, and the specific surface area is 65.7m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com