Oxygen-reduction and quality-guaranteeing processing method of Chinese walnut kernels

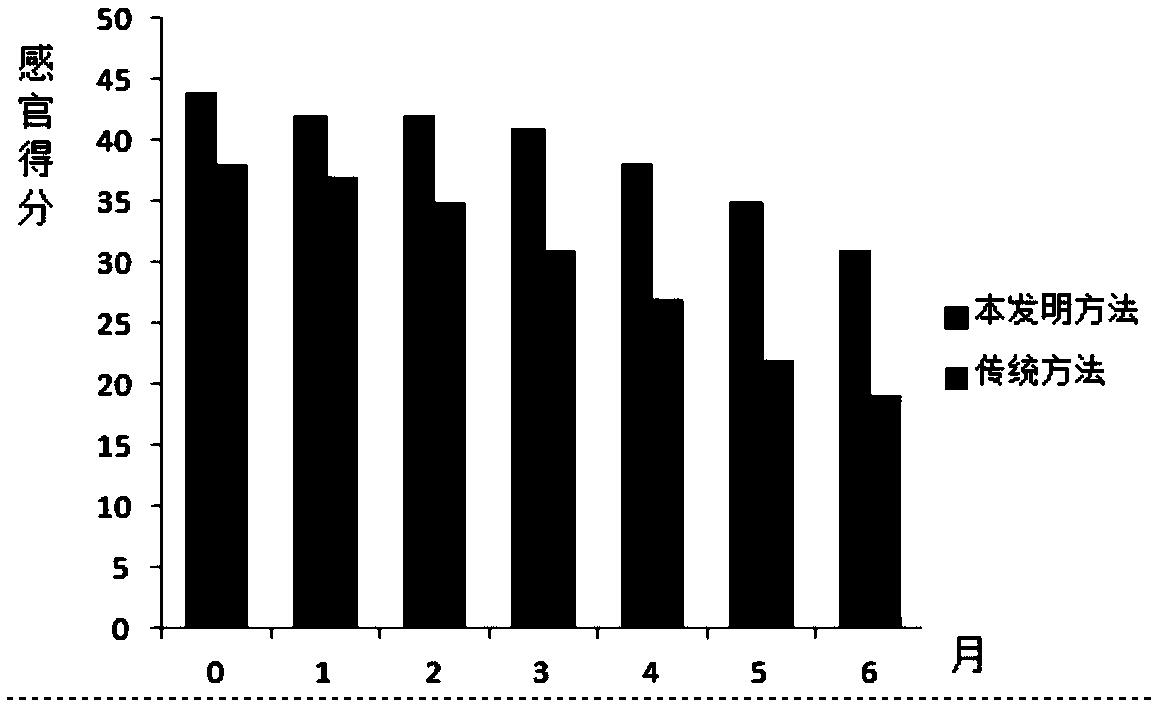

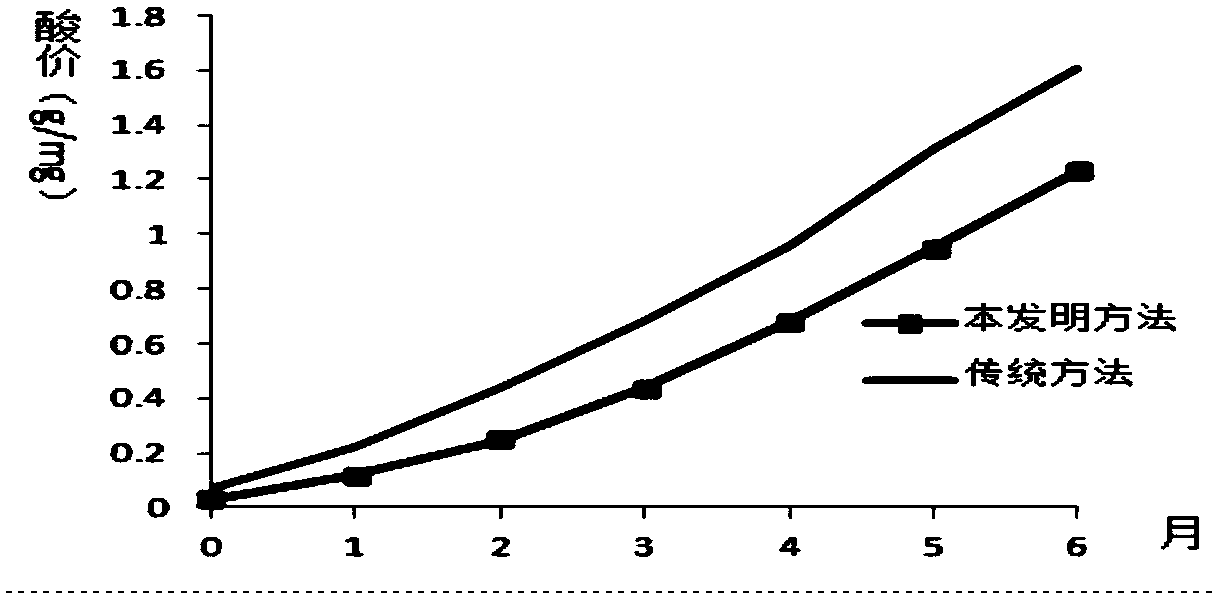

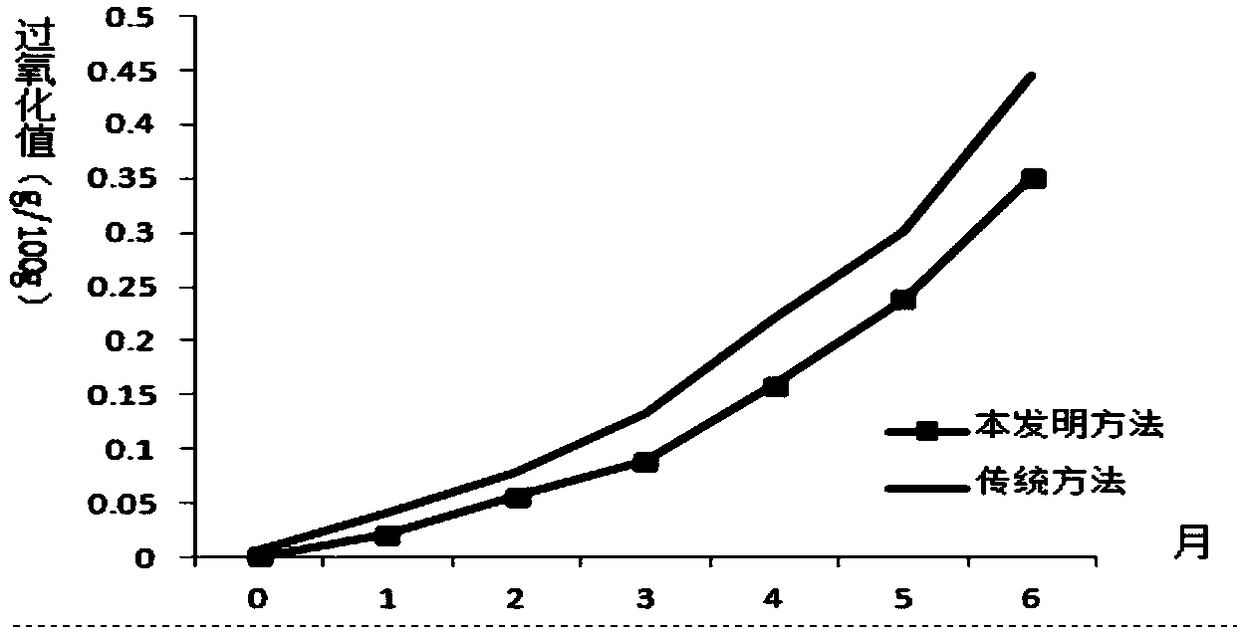

A processing method and technology of walnut kernels, which are applied in heating preservation of seeds, preservation of seeds with chemicals, preservation of seeds by freezing/cooling, etc., can solve the problem of easy oxidation of unsaturated fatty acids, high oil content, and nutritional value of finished products. Discount and other issues to achieve the effect of ensuring water loss, reducing oxygen, and reducing loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: a kind of processing method of hickory kernel by reducing oxygen and preserving quality, comprising the following steps:

[0036] (1) Low temperature removal of astringency: put 0.12% tannase aqueous solution in the sandwich pot, adjust the pH value to 4.6 with a small amount of citric acid, and pour the hickory kernels that have been selected and removed with the same weight as the astringent solution into the sandwich pot , heating to keep the temperature of the astringent-removing solution at 40°C for 50 minutes, remove it, rinse it with water 2-3 times, and drain the water;

[0037] (2) Vacuum flavoring: Put the hickory kernels obtained in step (1) into the vacuum flavoring equipment filled with room temperature seasoning liquid, seal the cover, and then vacuumize to keep the vacuum at -0.03mpa, flavoring for 12 minutes each time, cycle 3 (3) Standing at low temperature to equalize the taste: put the hickory kernels obtained in step (2) at 2° C. and a ...

Embodiment 2

[0041] Embodiment two: a kind of hickory nut kernel oxygen-reducing and quality-preserving processing method comprises the following steps:

[0042] (1) Low-temperature removal of astringency: put 0.15% tannase aqueous solution in the sandwich pot, adjust the pH value to 5.0 with a small amount of citric acid, and pour the hickory kernels that have been selected and removed with the same weight as the astringent solution into the sandwich pot , heating to keep the temperature of the astringent-removing solution at 35°C for 60 minutes, remove, rinse with water 2-3 times, and drain the water;

[0043] (2) Vacuum flavoring: Put the hickory kernels obtained in step (1) into a vacuum flavoring device filled with room temperature seasoning liquid, seal the cover, and then vacuumize to keep the vacuum at -0.05mpa, flavoring for 10 minutes each time, cycle 3 Second-rate;

[0044] (3) Standing at low temperature to equalize the taste: put the hickory kernels obtained in step (2) in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com