Siloxane toughened and modified SiO2 aerogel and preparation method thereof

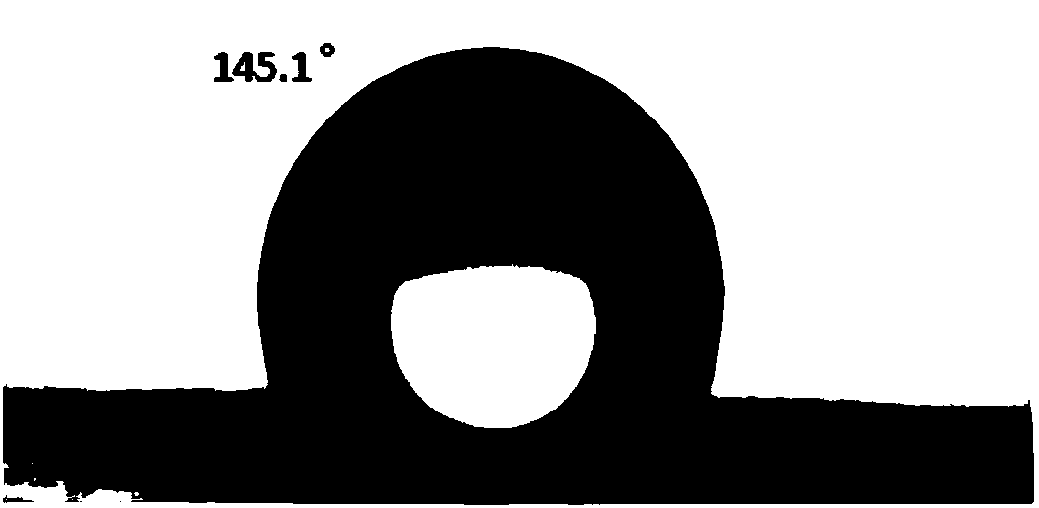

A technology of toughening modification and aerogel, which is applied in the direction of chemical instruments and methods, silicon oxide, silicon dioxide, etc., can solve the problems of low density, modification that does not reach the molecular level, etc., and achieve short time-consuming, excellent Water repellency and toughness, low density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A kind of siloxane toughened modified SiO 2 Airgel, the preparation method is as follows:

[0035] 1) Weigh 12.48g of ethyl orthosilicate and 27.64g of ethanol respectively (the molar ratio of ethyl orthosilicate to ethanol is 1:10), mix them, and add 0.312g of hydroxyl-terminated polydimethylsiloxane (orthosilicate The mass ratio of ethyl ester to hydroxyl-terminated polydimethylsiloxane is 1:0.025) and 0.156g of methyltriethoxysilane (the mass ratio of hydroxyl-terminated polydimethylsiloxane to methyltriethoxysilane 1:0.5), stir evenly to obtain a mixed solution;

[0036] 2) Measure 200 mL of deionized water, weigh 20.0 g of ammonia water with a mass concentration of 25%, and 2 g of ammonium fluoride, mix and prepare a catalyst (mass ratio of deionized water, ammonia water, and ammonium fluoride 1:0.1:0.01), and add to step 1) Add 0.96g0.2mol / L catalyst to the obtained mixed solution, stir evenly, pour it into a mold, and react at room temperature for 5min to obtai...

Embodiment 2

[0043] A kind of siloxane toughened modified SiO 2 Airgel, the preparation method is as follows:

[0044] 1) Weigh 14.58g of ethyl orthosilicate and 112.85g of ethanol respectively (the molar ratio of ethyl orthosilicate to ethanol is 1:35), mix them, and add 1.458g of hydroxyl-terminated polydimethylsiloxane (orthosilicate The mass ratio of ethyl ester to hydroxyl-terminated polydimethylsiloxane is 1:0.1) and 0.729g of methyltriethoxysilane (the mass ratio of hydroxyl-terminated polydimethylsiloxane to methyltriethoxysilane 1:0.5), stir evenly to obtain a mixed solution;

[0045] 2) Measure 200 mL of deionized water, weigh 20.0 g of ammonia water with a mass concentration of 25%, and 8 g of ammonium fluoride, mix and prepare a catalyst (mass ratio of deionized water, ammonia water, and ammonium fluoride 1:0.1:0.04), and add to step 1) Add 1.12 g of 0.9 mol / L catalyst (mass ratio of ethyl orthosilicate to catalyst: 13:1) to the obtained mixed solution, stir evenly, pour it i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Hydrophobic angle | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com