Molybdenum and molybdenum-vanadium co-doped nano silicon oxide based catalyst, preparation method and application thereof

A nano-silica, silicon oxide-based technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, carbon-based compound preparation, etc., can solve the problems of long synthesis cycle and complex synthesis steps , to achieve the effects of short preparation cycle, simple preparation method and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] A metal molybdenum framework doped mesoporous nano-SiO 2 Particle catalysts in which Mo:Si molar ratio is 0.1:100 Mo-SiO 2 The catalyst is obtained through the following preparation steps:

[0067] (1) Weigh the corresponding mass (NH 4 ) 6 Mo 7 o 24 Add 15mL of deionized water, heat and stir in a 35°C water bath for 1 hour, then dissolve to form a uniform phase A;

[0068] (2) Weigh 0.5g of CTAB and dissolve it in 55mL of deionized water, add 15mL of ethanol and stir until completely dissolved to obtain solution B;

[0069] (3) Use a pipette to take 15mL of diethyl ether and drop 0.8mL of ammonia water into solution B, stir for 20 minutes, add uniform solution A, and stir for 5 minutes;

[0070] (4) Take 2.5mL TEOS and quickly drop them into the mixed solution of A and B, stir vigorously for 3h, adjust the pH to 7 with hydrochloric acid solution and continue stirring for 1h. The white precipitate was obtained after filtering (water pump decompression system), wa...

Embodiment 2

[0075] A metal molybdenum framework doped mesoporous nano-SiO 2 Particle catalyst, Mo-SiO with Mo:Si molar ratio of 10:100 2 The preparation steps of the catalyst are the same as in Example 1, except that the doping amount of metal molybdenum is different, which is recorded as 10Mo-m-SiO 2 .

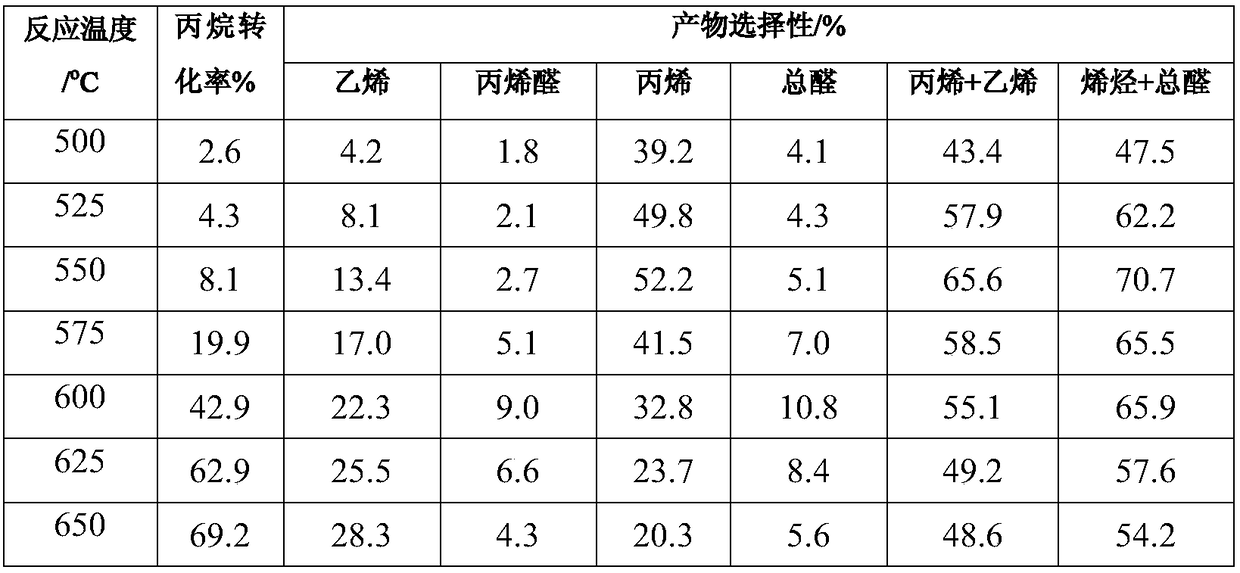

[0076] The method for catalyzing the selective oxidation reaction of propane adopted by the catalyst, and the detection and analysis method of reactants are all the same as those in Example 1. Table 2 is 10Mo-m-SiO 2 Selective distribution of main products in selective oxidation of propane over catalyst.

[0077] Table 2 10Mo-m-SiO 2 Selective Distribution of Main Products in Selective Oxidation of Propane over Catalyst

[0078]

Embodiment 3

[0080] A metal molybdenum framework doped mesoporous nano-SiO 2 Particle catalyst in which the Mo:Si molar ratio is 3:100 Mo-SiO 2 The preparation steps of the catalyst are the same as in Example 1, except that the doping amount of metal molybdenum is different, which is denoted as 3Mo-m-SiO 2 .

[0081] The method for catalyzing the selective oxidation reaction of propane adopted by the catalyst, and the detection and analysis method of reactants are all the same as those in Example 1. Table 3 is 3Mo-m-SiO 2 Selective distribution of main products in selective oxidation of propane over catalyst.

[0082] Table 3 3Mo-m-SiO 2 Selective Distribution of Main Products in Selective Oxidation of Propane over Catalyst

[0083]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com