Immobilized lipase and preparation method thereof

A technology of immobilized lipase and lipase, which is applied in the direction of biochemical equipment and methods, fixed on/in organic carriers, enzymes, etc., can solve the problems of low reuse rate of immobilized enzymes, leakage of enzyme molecules, condensation Solve the problems of poor mechanical strength of rubber beads, and achieve good thermal stability and reusability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: Obtaining of immobilized lipase

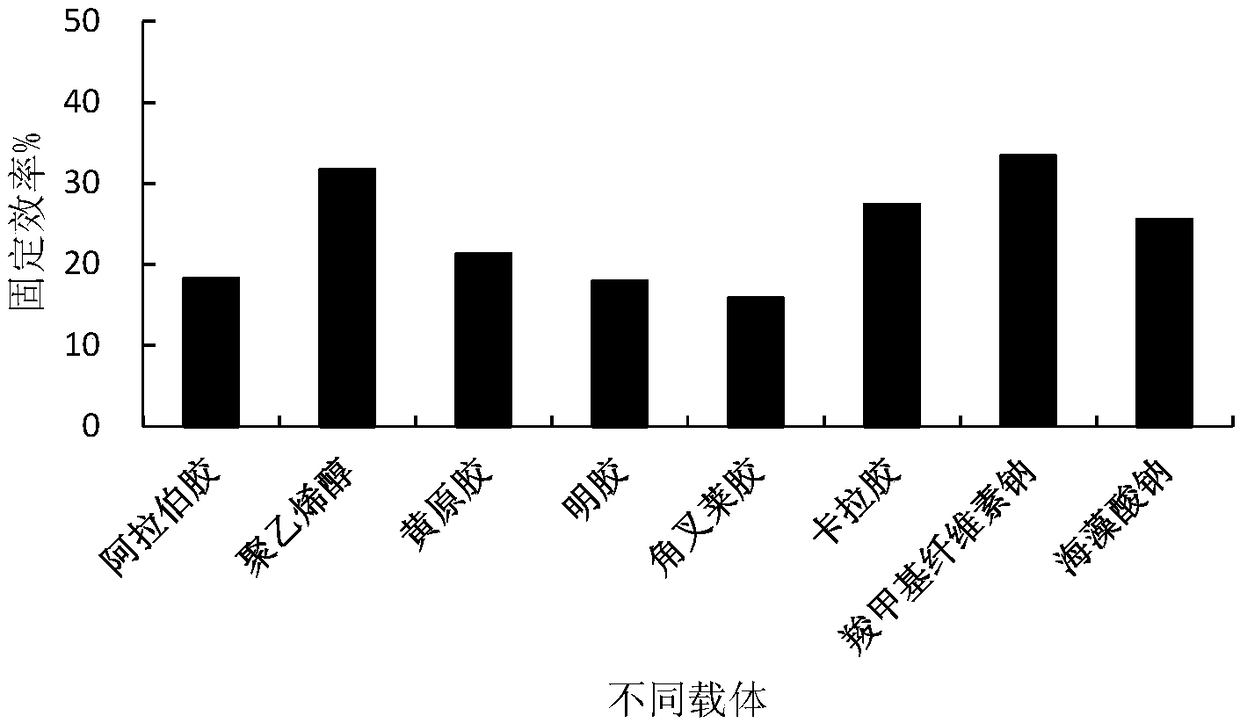

[0021] 1.1 Screening the carrier compounded with sodium alginate

[0022] Set the concentration of the compound carrier in the compound carrier solution to be 2.5% by mass fraction, choose sodium alginate-gum arabic (mass ratio 3:2), sodium alginate-polyvinyl alcohol (mass ratio 3:2), seaweed Sodium alginate-xanthan gum (mass ratio 3:2), sodium alginate-gelatin (mass ratio 3:2), sodium alginate-carrageenan (mass ratio 3:2), sodium alginate-carrageenan ( Mass ratio 3:2), sodium alginate-sodium carboxymethyl cellulose (CMC) (mass ratio 3:2) was used as embedding carrier to study the immobilization of lipase.

[0023] The specific steps are:

[0024] S1. Weigh 1.5g of sodium alginate and 1g of gum arabic, add it to 97.5g of pH7.0 phosphate buffer, heat to dissolve, and stir and mix evenly to obtain a sodium alginate-gum arabic compound carrier solution; weigh 1.5g Add 97.5g of sodium alginate and 1g of polyvinyl alcohol in...

Embodiment 2

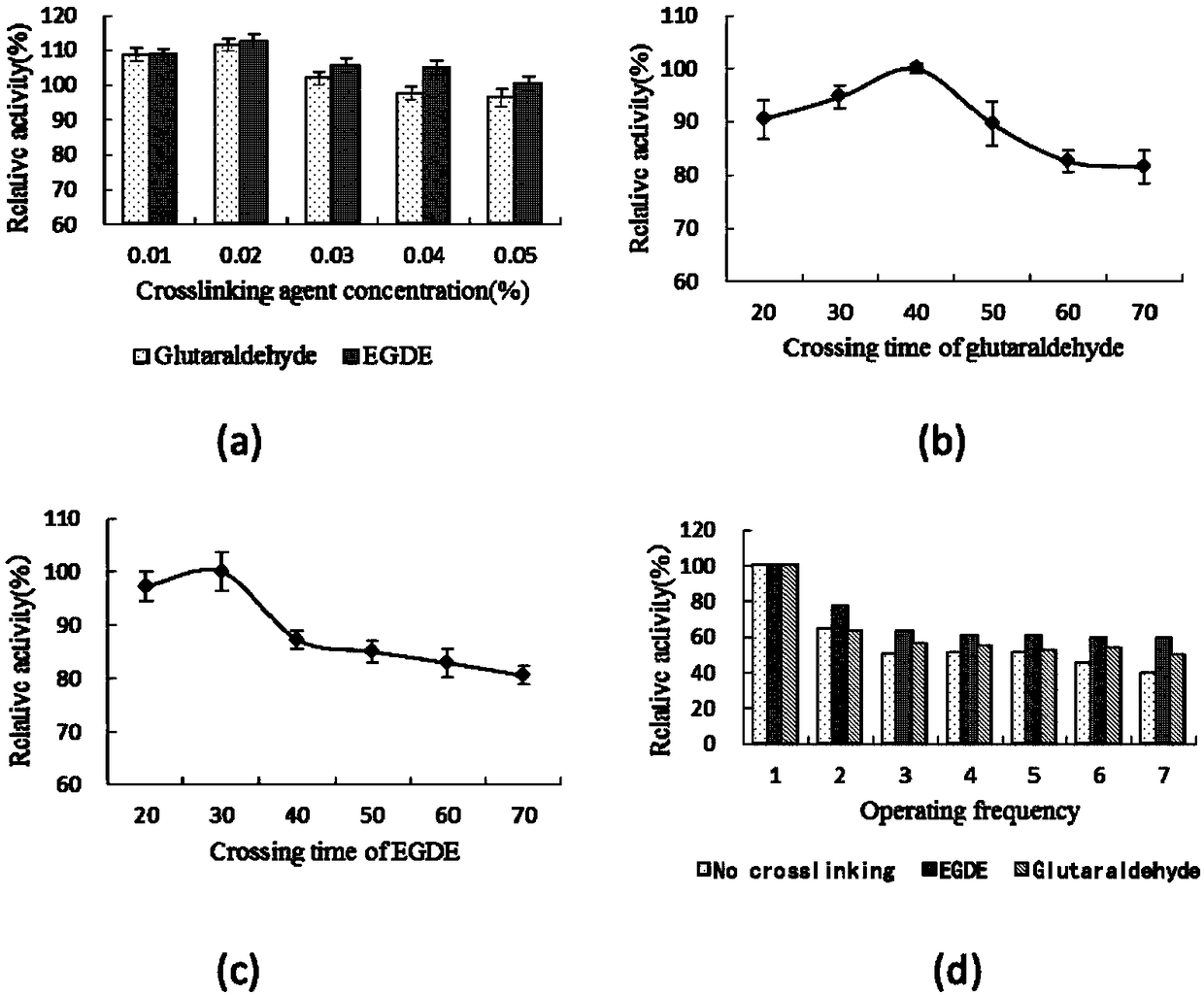

[0070] Example 2: Cross-linking of immobilized lipase

[0071] 2.1 The effect of cross-linking agent concentration on the activity of immobilized lipase

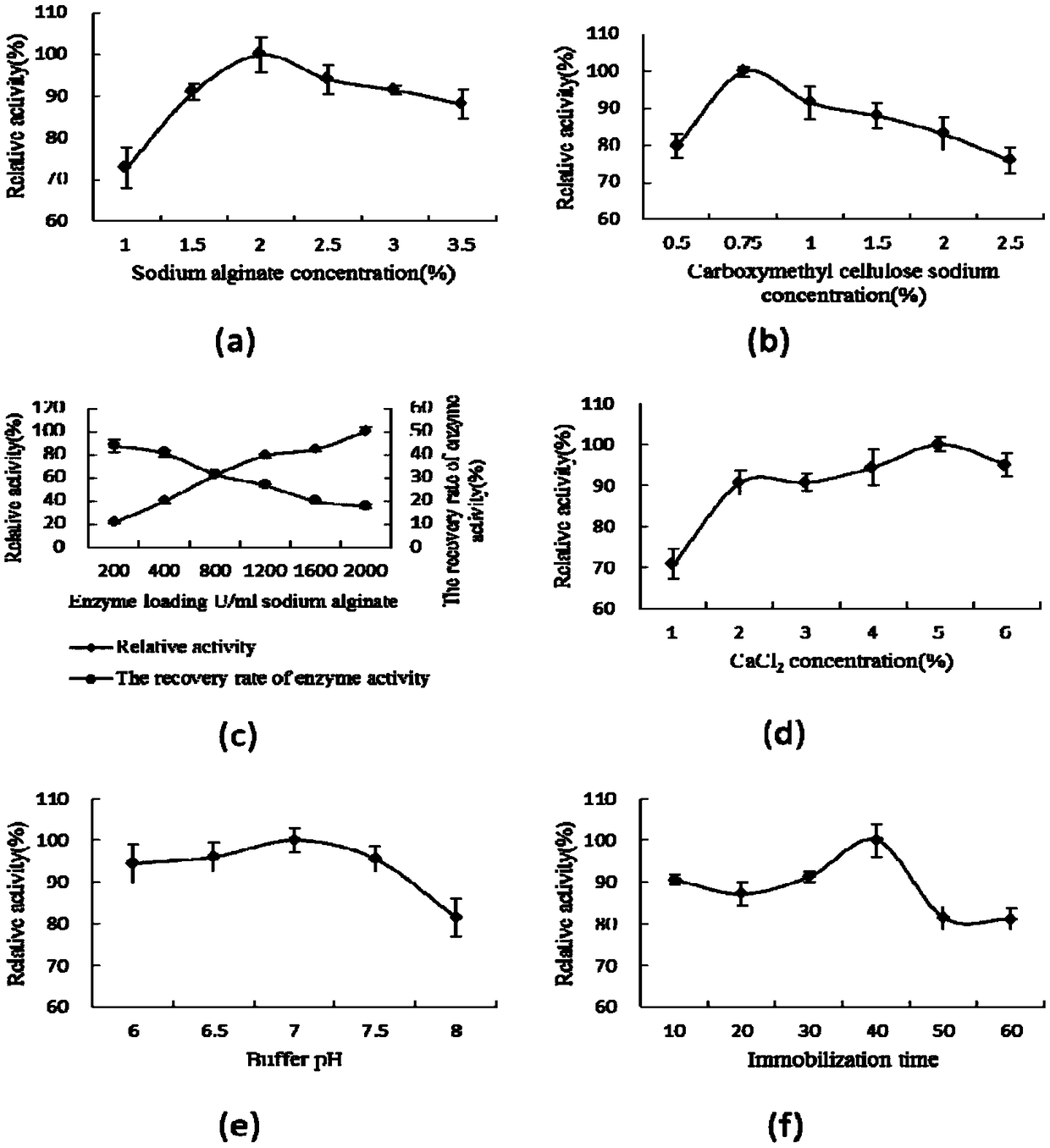

[0072] According to the content of sodium alginate in the composite carrier solution is 2.5% by mass fraction, the content of CMC is 1.5% by mass fraction, the concentration of calcium chloride solution is 5% by mass fraction and the fixation time is 50min, the effect of crosslinking agent concentration on immobilized lipase is studied. effect on enzyme activity.

[0073] The specific steps are:

[0074] S1. Weigh 2.5g sodium alginate and 1.5g CMC and add them to 96g pH7.0 phosphate buffer solution, heat to dissolve, and stir and mix evenly to obtain sodium alginate-CMC composite carrier solution P (sodium alginate content is 2.5% by mass fraction, and the content of CMC is 1.5% by mass fraction); lipase (Shenzhen Hengsheng Biotechnology Co., Ltd., article number: 9001-62-1) is dissolved in the phosphate buffer solution of...

Embodiment 3

[0086] Example 3: Comparison of enzymatic properties between immobilized lipase and free lipase after crosslinking

[0087] 3.1 The optimal reaction pH of immobilized lipase and free lipase

[0088] Set the pH of the enzymatic reaction system to 6-10, measure the enzymatic activity of immobilized lipase and free lipase at 40°C, the results are shown in Figure 4 a. Depend on Figure 4 It can be seen that the optimal reaction of the immobilized lipase (preparation method is the same as embodiment 2 step 2.3) of EGDE crosslinking, glutaraldehyde crosslinking immobilized lipase (preparation method is the same as embodiment 2 step 2.3) and free lipase The pHs were 8.5, 8.0 and 8.0, respectively. Compared with free lipase and glutaraldehyde-crosslinked immobilized lipase, the optimal pH of the reaction system of EGDE-crosslinked immobilized lipase shifted to the alkaline direction, and when the pH was between 8.0 and 9.0, it showed Higher enzyme activity. 3.2 Optimum reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com