Natural gas smoke waste heat complete heat recovery device

A flue gas waste heat and total heat recovery technology, applied in the field of emission devices, can solve the problems of large-capacity recovery equipment, bulky, unsuitable for energy-saving renovation of established power plants, and unused flue gas waste heat, etc., to reduce heating costs , stable performance, and the effect of improving the heat-to-electricity ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

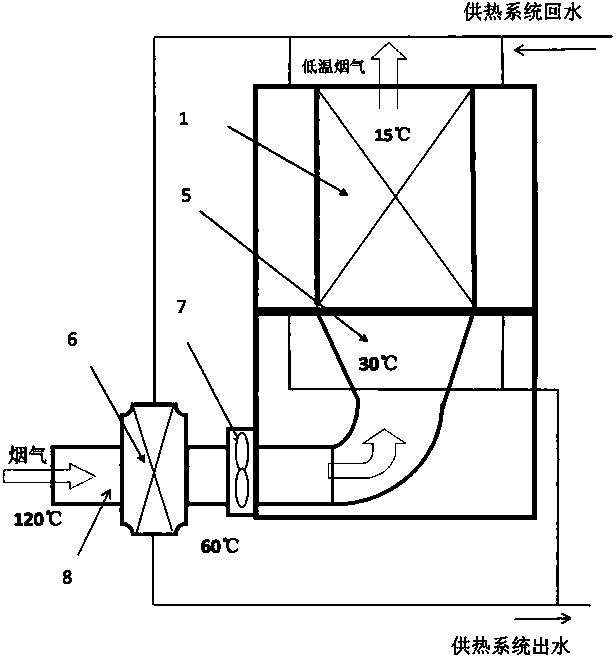

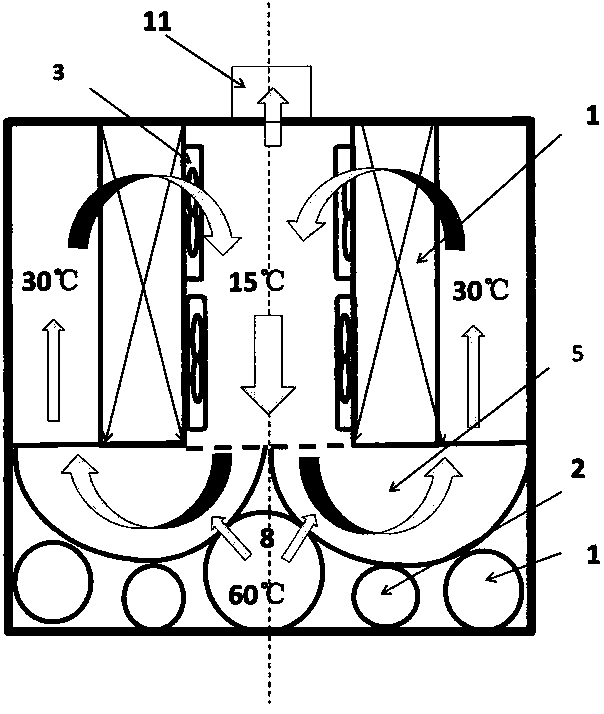

[0057] Embodiment 1: (attach Figure 5 )

[0058] This embodiment is a typical implementation method of the technology of the present invention. It is applicable to the waste heat recovery of flue gas in the built gas-steam combined cycle heat and power cogeneration power plant, without any modification inside the power plant. On the flue gas side, it is only necessary to connect a high-temperature flue to the chimney to lead the flue gas at 90°C into the gas-water heat exchanger to cool down to medium-temperature flue gas (about 60°C), and introduce skid-mounted gas flue gas waste heat through the fan for full heat recovery In the device, the flue gas enters the mixing cooler through the flue to drop to 30±5°C, then enters the heat pump evaporator to drop to 15±5°C, and is discharged to the atmosphere from the low-temperature flue. The circulating return water of the heating system enters the condenser for heat exchange and rises in temperature, and then is pressurized by t...

Embodiment 2

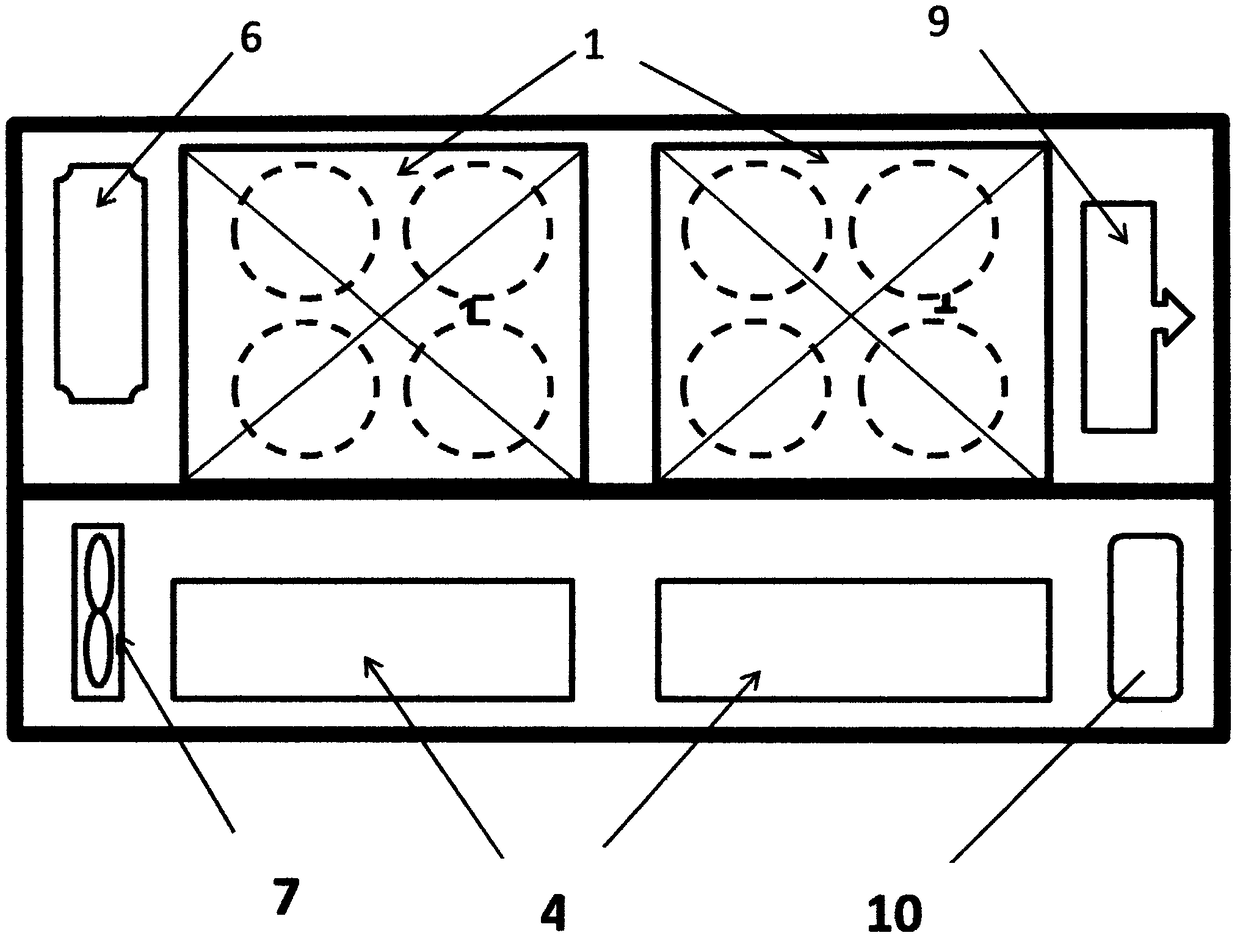

[0059] Embodiment 2: (attach Figure 6 )

[0060] This embodiment is a typical implementation method of the technology of the present invention. It is suitable for the flue gas waste heat recovery of the built gas-steam combined cycle cogeneration power plant. There is no space and area to install the waste heat recovery device inside and outside the power plant. It is necessary to add an equipment platform to the space above the chimney of the power plant or boiler room to recover the waste heat. The device is mounted on the platform. On the flue gas side, it is only necessary to connect a high-temperature flue to the chimney to lead the flue gas at 90°C into the gas-water heat exchanger to cool down to medium-temperature flue gas (about 60°C), and introduce the gas flue gas waste heat total heat recovery device through the fan, and the flue gas The gas passes through the flue in the device and enters the mixing cooler to drop to 30±5°C, and then enters the heat pump evapor...

Embodiment 3

[0062] This embodiment is an implementation method of the technology of the present invention. It is suitable for the energy-saving transformation of the built-in gas combustion equipment whose flue gas temperature is lower than 70°C. In recent years, some gas-fired boilers have undergone energy-saving transformation and installed a first-level flue gas waste heat recovery device. The exhaust gas temperature is lower than 70°C, and some sensible heat and most latent heat are still wasted without recovery. In this scheme, the flue gas connected to the fan is installed on the original chimney, and the flue gas below 70°C is introduced into the skid-mounted gas flue gas waste heat total heat recovery device through the fan. ±5°C, and then enter the heat pump evaporator to drop to 15±5°C, and discharge to the atmosphere from the low-temperature flue. The circulating return water of the heating system enters the condenser for heat exchange and rises in temperature, and then is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com