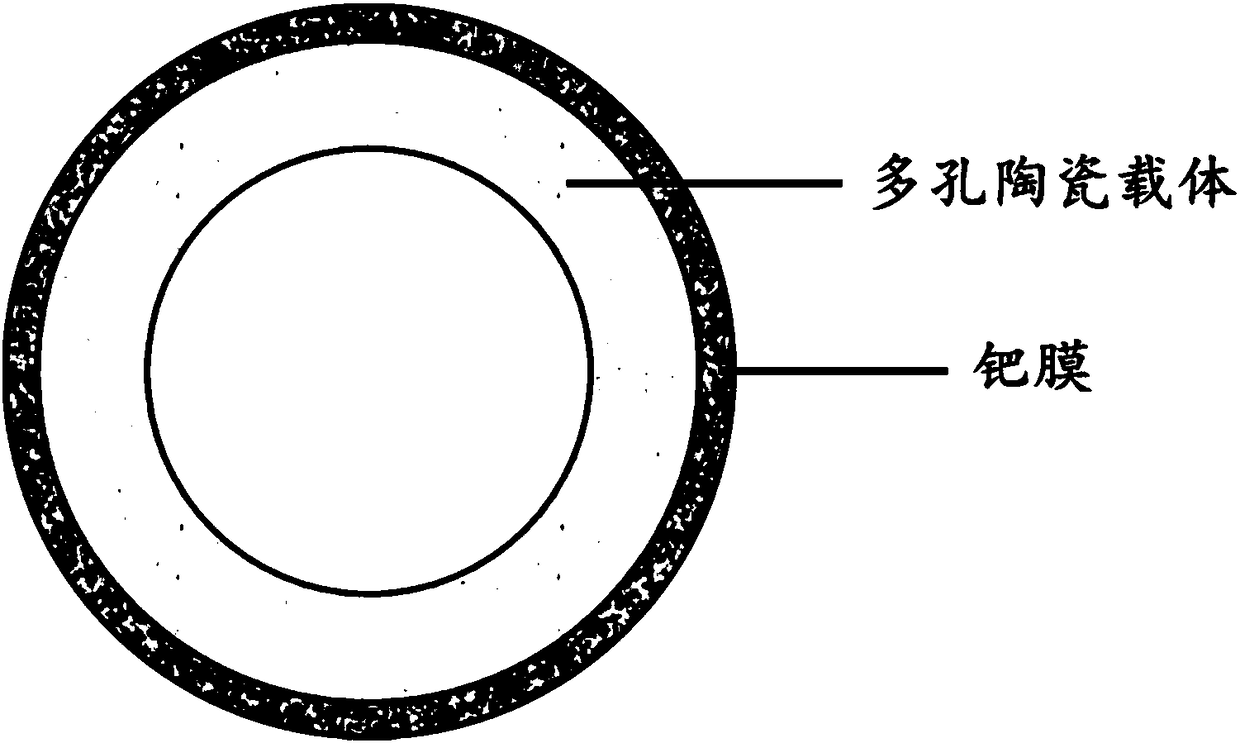

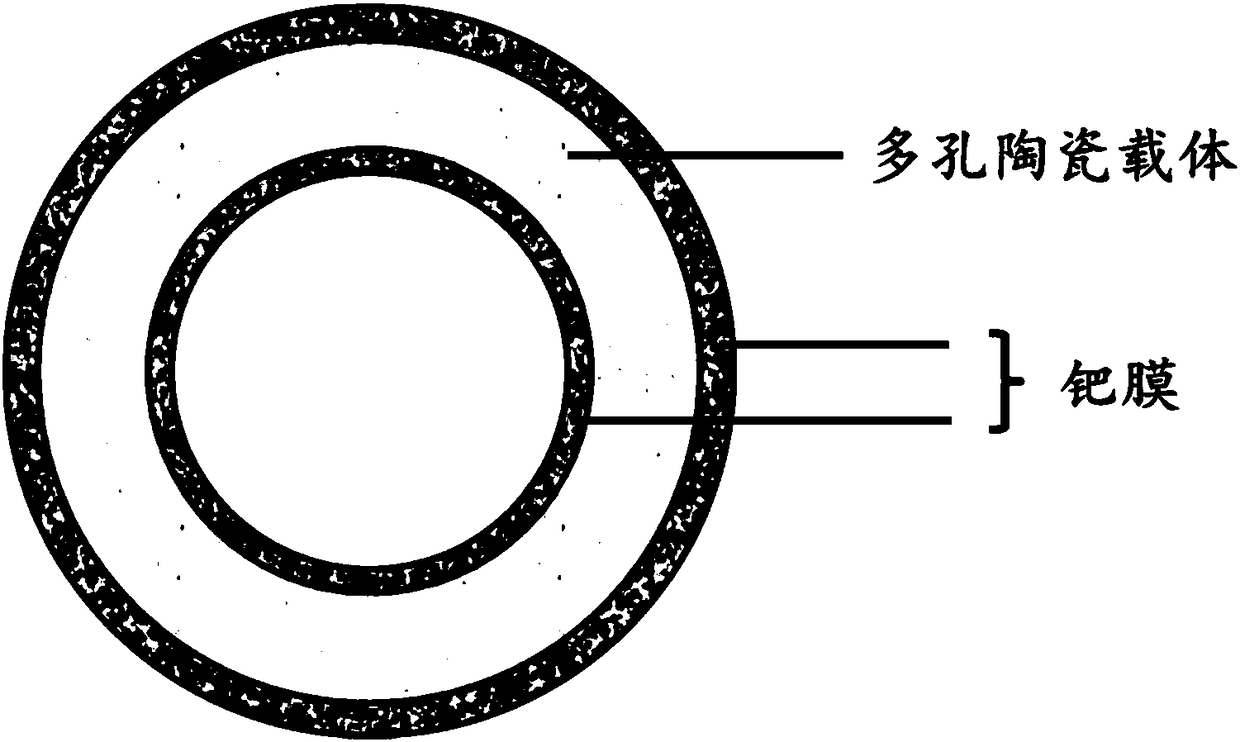

Preparation method and application of palladium-ceramic-palladium bilayer composite membrane material

A technology of composite membranes and membrane materials, applied in the direction of separation methods, chemical instruments and methods, membrane technology, etc., can solve the possibility of increasing the impurity gas permeation membrane materials, palladium membrane is difficult to cover the surface carrier, single-layer palladium membrane Defects are difficult to control and other problems, to achieve the effect of reducing equipment investment capital, reducing the probability of generation, and high hydrogen permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Single-layer palladium film with an outer layer of 4 μm

[0032] 1. Vector pretreatment

[0033] The porous ceramic carrier tube is 60 mm long and has an outer diameter of 14.05 mm. First in absolute ethanol (99.9%) NaCO 3 solution (NaCO 3 concentration of 0.10mol / L) for 15 minutes to remove impurities such as oil stains on the surface. Then immerse and wash in distilled water at 50°C for 30 minutes to remove residual alcohol solution. Finally, dry it in an oven at 150°C for later use, and the program is set as:

[0034]

[0035] Sensitize the oven-dried porous ceramic tube carrier, immerse in reducing agent (dimethylaminoborane), reduce for 5 minutes, rinse the carrier tube with distilled water, then immerse in 0.05mol / L palladium sulfate and 0.02mol / L of borax mixture to activate the palladium nucleus. The cycle was repeated 5 times until the color of the surface of the carrier film changed from white to black gray. So far, the palladium core is evenly cove...

Embodiment 2

[0047] 2μm inner layer and 2μm outer palladium film

[0048] 1. Vector pretreatment

[0049] The porous ceramic carrier tube is 60 mm long and has an outer diameter of 14.05 mm. First in absolute ethanol (99.9%) NaCO 3 solution (NaCO 3 concentration of 0.10mol / L) for 15 minutes to remove impurities such as oil stains on the surface. Then immerse and wash in distilled water at 50°C for 30 minutes to remove residual alcohol solution. Finally, dry it in an oven at 150°C for later use, and the program is set as:

[0050]

[0051] Sensitize the oven-dried porous ceramic tube carrier, immerse in reducing agent (dimethylaminoborane), reduce for 5 minutes, rinse the carrier tube with distilled water, then immerse in 0.05mol / L palladium sulfate and 0.02mol / L of borax mixture to activate the palladium nucleus. The cycle was repeated 5 times until the color of the surface of the carrier film changed from white to black gray. So far, the palladium core is evenly covered, and th...

Embodiment 3

[0071] Single-layer palladium film with an outer layer of 4 μm, performance test under simulated industrial conditions

[0072] 1. Vector pretreatment

[0073] Processing method is with embodiment 1.

[0074] 2. Electroless palladium plating film

[0075] Implementation method is the same as embodiment 1.

[0076] 3. Activation treatment and performance evaluation of palladium membrane

[0077] (1) Activation treatment

[0078] Concrete operation method, with embodiment 1.

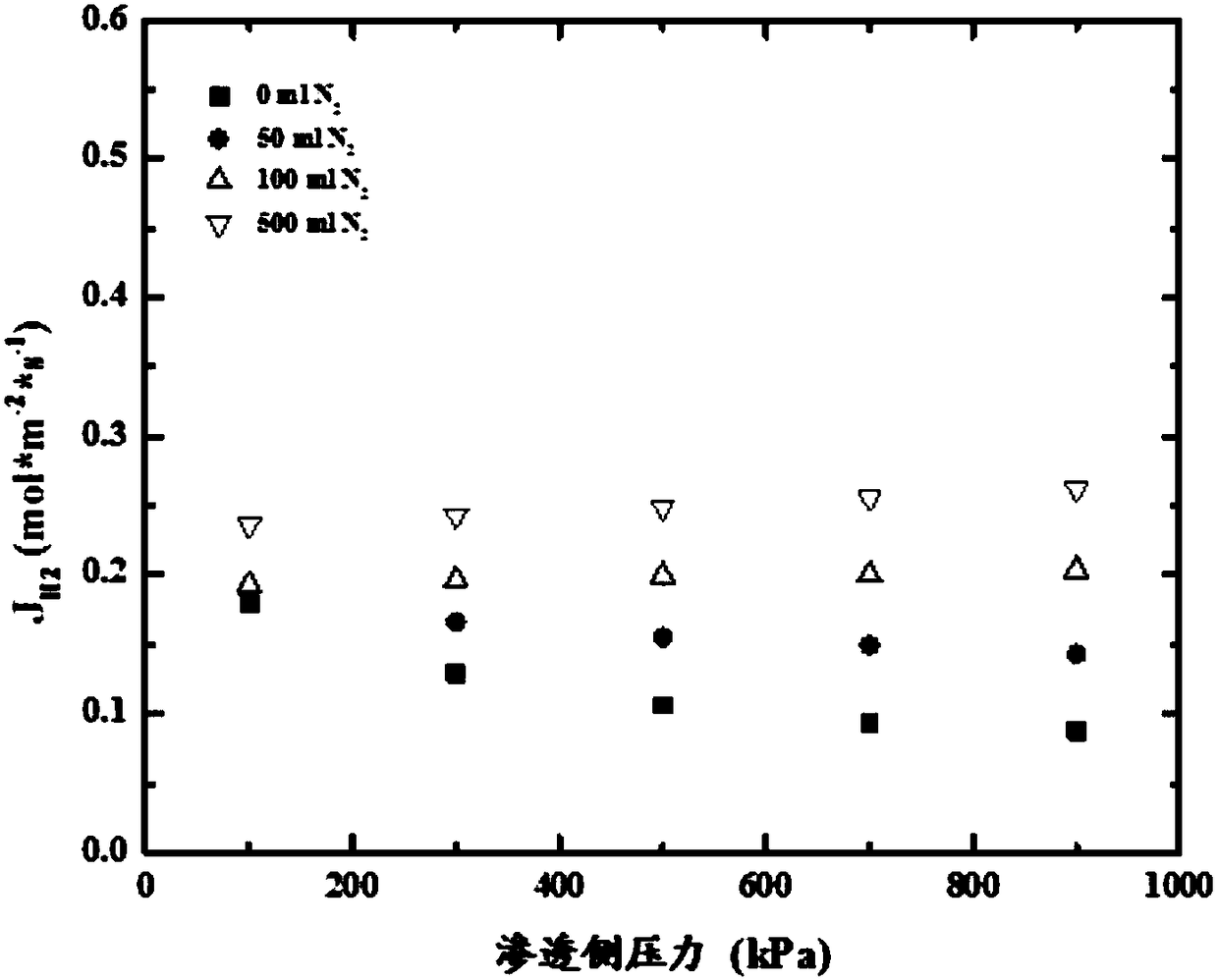

[0079] (2) Performance test of membrane material

[0080] In a simulated industrial environment, with 450ml H 2 :400ml N 2Ratio, feed reaction gas, purge side with 400ml / min N 2 , the pressure on the reaction side was kept at 2MPa, the pressure on the permeate side was tested from 0.8MPa, and then the pressure on the permeate side was reduced to 0.6MPa, 0.4MPa, 0.2MPa and 0.1MPa, respectively, and the hydrogen permeation performance under these conditions was measured. For specific experimental res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Relative density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com