Insulin precursor precipitation recovery method for removing amino acid residue at 30th of chain B

A technology of insulin precursor and recovery method, applied in the field of preparation of recombinant human insulin, can solve the problems of incomplete reaction, great difference in enzyme cleavage rate, large loss of process yield, etc., so as to simplify the production process and improve the yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In this example, the DesB30 digestion reaction system before precipitation was prepared. For the preparation of fermentation supernatant, refer to "Technical Research on the Conversion of Recombinant Insulin Precursor to Adult Insulin and Detemir", Liu Haifeng, East China University of Science and Technology, PhD thesis (2013). The fermentation supernatant was diluted with deionized water to 10 times the original volume, and an appropriate amount of citric acid was weighed and dissolved in the diluted sample to a final concentration of 20 mmol / L.

[0039] Ion chromatography purification was performed on a chromatography workstation using CM SepharoseFF (XK26 / 200, 50ml).

[0040] The balance solution is 20mmol / L citric acid+0.01mol / L NaCl.

[0041] Washing solution A is 20mmol / L citric acid+0.1mol / L NaCl.

[0042] Washing solution B is 5mmol / L hydrochloric acid, and the eluent is 0.1mol / L ammonium bicarbonate buffer.

[0043] Except the eluent, all solutions (including sample lo...

Embodiment 2

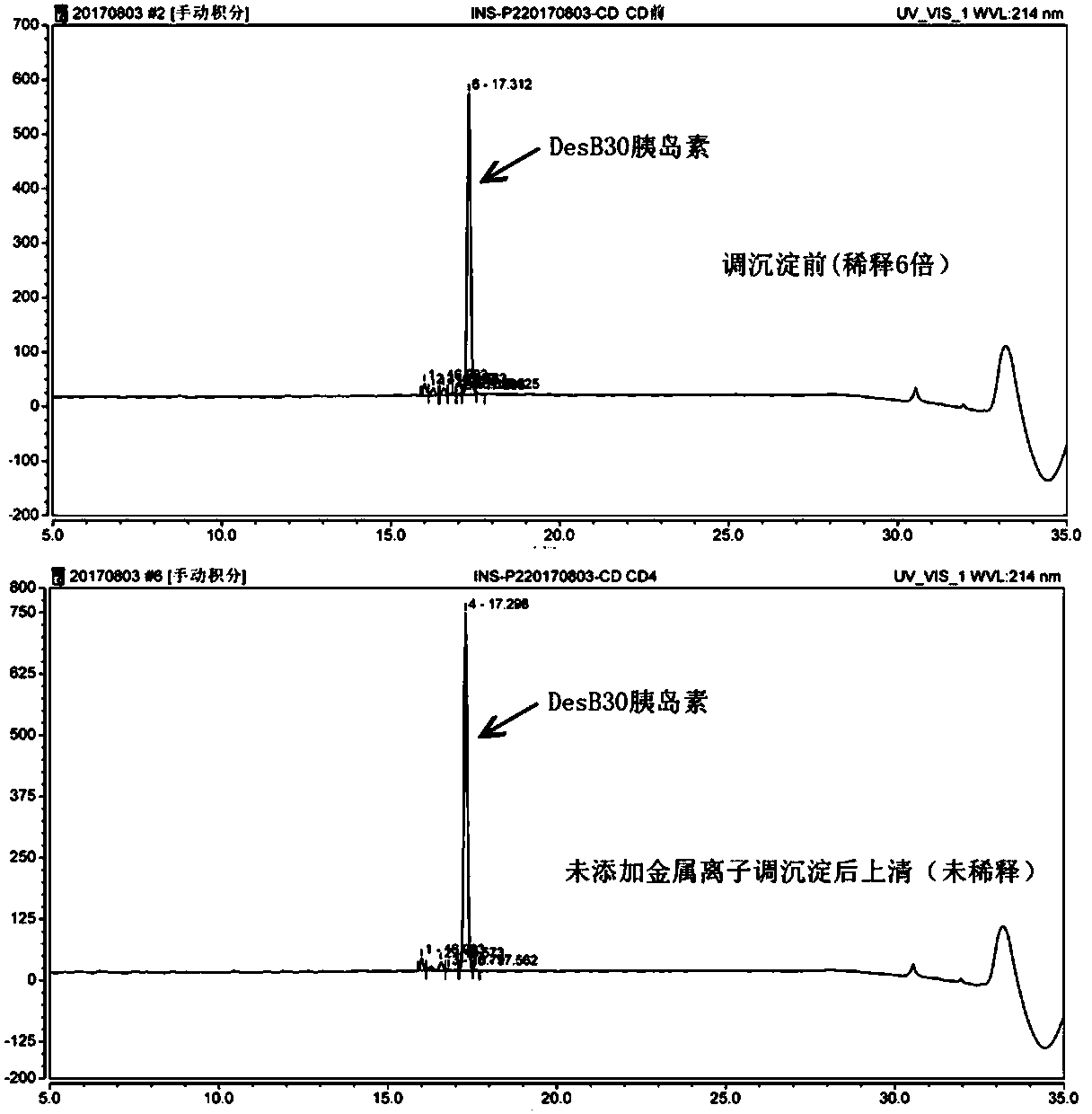

[0052] No metal ions are added to precipitate DesB30 insulin.

[0053] The DesB30 digestion reaction system before precipitation was prepared according to Example 1, and the concentration of DesB30 in the supernatant detected by HPLC was 3.20 g / L. The pH of the digested reaction system was adjusted to 4.5 with hydrochloric acid, and after precipitation at 4°C for 1 hour, the supernatant was taken from the HPLC to determine the content of DesB30 in the supernatant to be 0.69g / L, and the residual DesB30 insulin in the supernatant was 21.56% . figure 1 The HPLC comparison chart before and after precipitation of DesB30 without adding metal ions in this example.

Embodiment 3

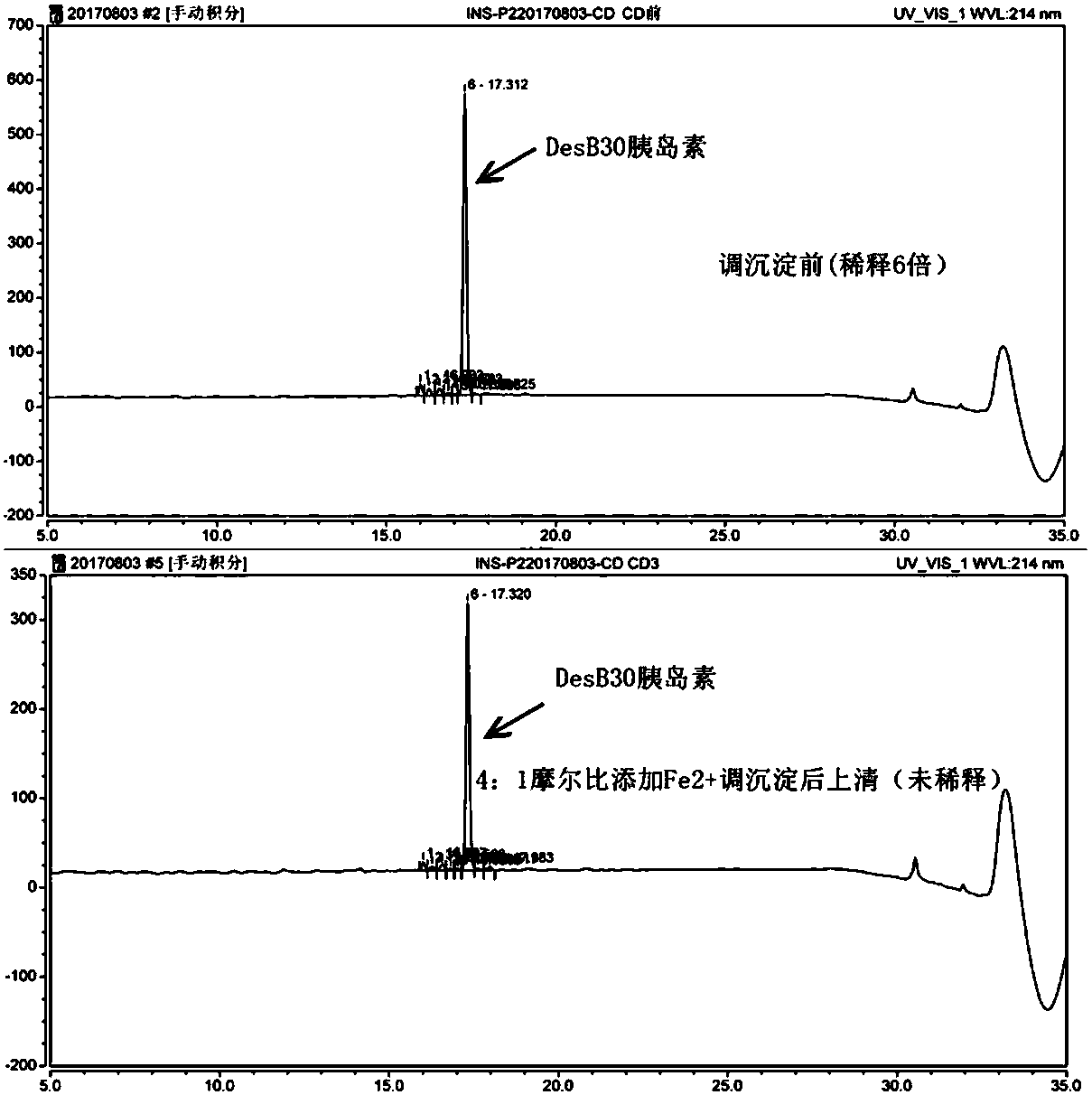

[0055] Add Fe according to the molar ratio of metal ion: DesB30 to 4:1 2+ Precipitate DesB30 insulin.

[0056] Refer to the preparation method of Example 1, take 1L of DesB30 digestion reaction system before precipitation, and add 11.23ml of 0.2mol / L FeSO 4 ·7H 2 After stirring the O aqueous solution, adjust the pH to 4.5 with 6M hydrochloric acid, and after 1h precipitation at 4℃, take the supernatant and HPLC to detect the content of DesB30 in the supernatant and the content of DesB30 in the supernatant is 0.29g / L. Compared with no metal ions added, the residual rate of DesB30 insulin in the supernatant is reduced by 2.4 times. figure 2 The HPLC comparison chart before and after precipitation of DesB30 in this example.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com