A kind of durable antibacterial waterborne wood coating and preparation method thereof

A wood coating, water-based technology, applied in the field of coatings, can solve the problem that the durability of antibacterial effect needs to be studied, and achieve the effect of excellent board surface effect, fine and smooth surface, and good antibacterial performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

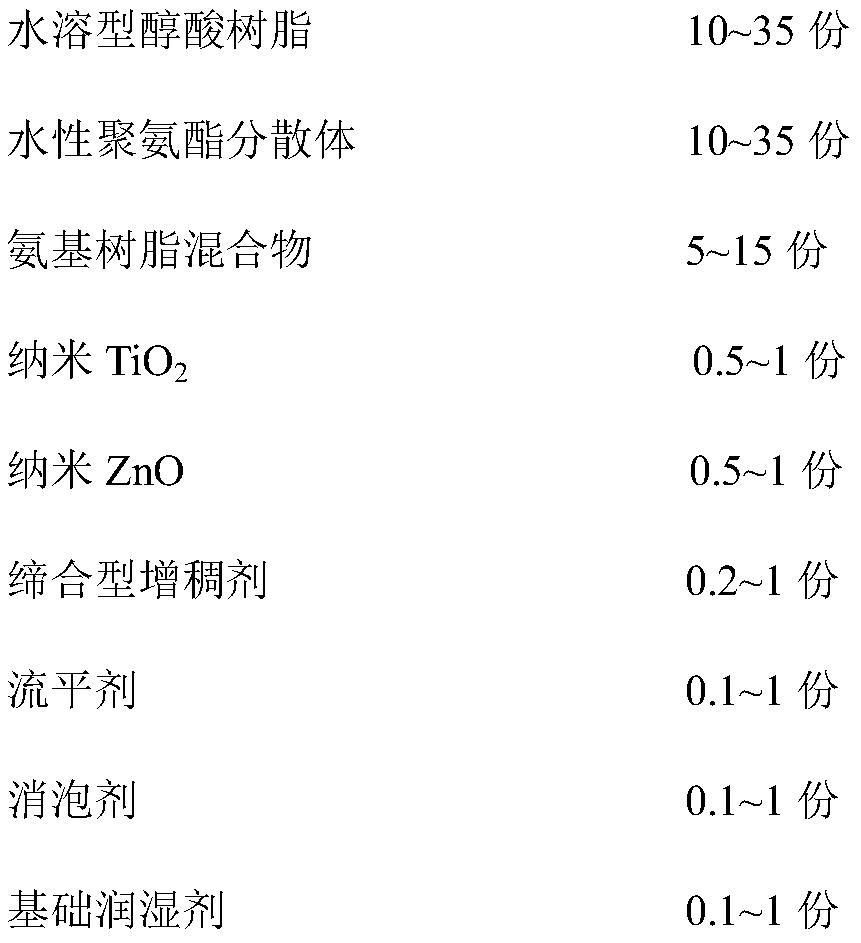

Method used

Image

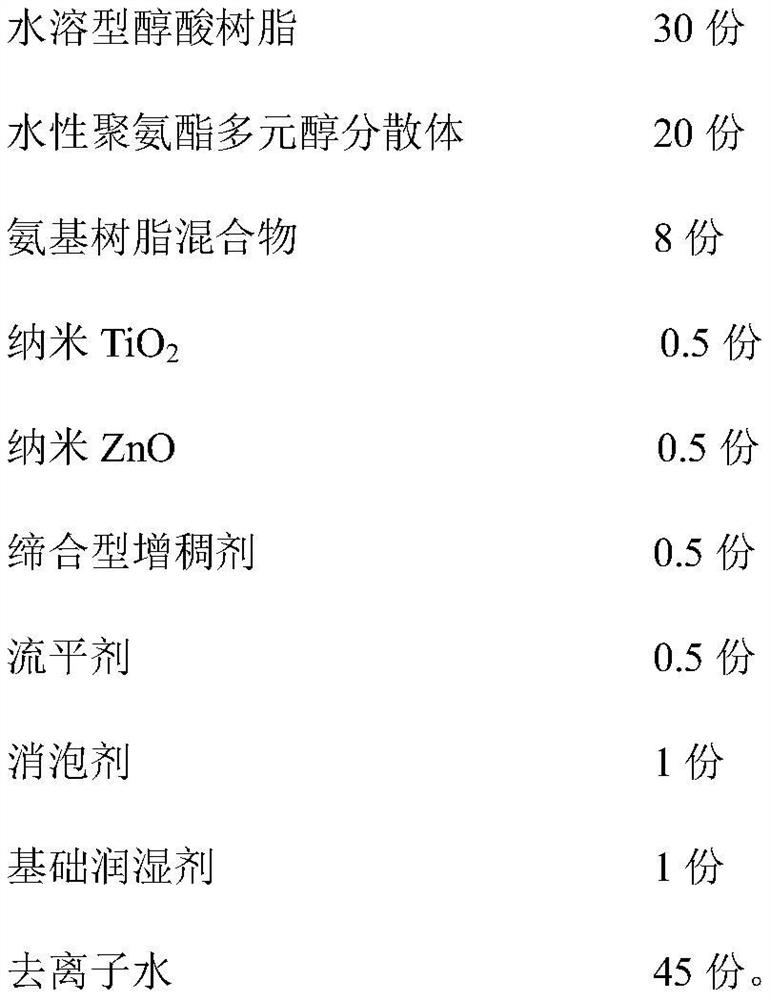

Examples

Embodiment 1

[0042] The preparation of embodiment 1 water-soluble alkyd resin

[0043] The preparation raw material composition of embodiment 1 water-soluble alkyd resin is shown in the following table:

[0044] raw material Recipe 1 Recipe 2 Recipe 3 Recipe 4 Artemisia oil 35 30 35 40 pentaerythritol 20 15 15 20 Propylene Glycol 15 10 15 15 Phthalic anhydride 20 10 15 20 Adipic acid 5 9 6 5 lithium hydroxide 0.08 0.05 0.06 1 p-Toluenesulfonic acid 0.08 0.05 0.06 1

[0045] Preparation:

[0046] Under the protection of nitrogen, put the formula amount of artemisia annua oil, pentaerythritol, propylene glycol and lithium hydroxide in the reactor, mix well, first raise the temperature to 100°C, and then raise the temperature to 200°C at a rate of 25°C / h for reaction 12h, cool down to 100°C, then add phthalic anhydride, adipic acid and p-toluenesulfonic acid, raise the temperature to 220°C at a heating rate o...

Embodiment 2

[0047] The preparation of embodiment 2 ketone cross-linked polyamide polyamine epichlorohydrin

[0048] Take polyamide and dissolve it in 0.15mol / L hydrochloric acid solution, stir until it is completely dissolved to make a polyamide solution with a concentration of 5% (m / v), and then add pre-dissolved polyamide with a concentration of 2% (m / v). Methylisothiazolinone / isothiazolinone aqueous solution, react at room temperature for 3h, the weight ratio of the polyamide to methylisothiazolinone / isothiazolinone is 1:0.2, then the reaction solution is dried under reduced pressure and pressed into powder, then disperse the powder in water to make the solid content reach 25%, heat to 35°C, slowly add epichlorohydrin, keep the pH of the system at 7.5, react for 2h, the amount of epichlorohydrin added 15% by weight of the polyamide, reacted at 70°C for 3 hours, adjusted the pH to 3.0 with hydrochloric acid, and dried under reduced pressure to obtain ketone cross-linked polyamide polyam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com