Preparation method of tin disulfide/graphene/tin dioxide ternary composite gas-sensing material for nitrogen dioxide gas sensor

A nitrogen dioxide, tin disulfide technology, applied in chemical instruments and methods, tin oxide, graphene and other directions, can solve the problems of poor selectivity, high working temperature, high detection limit, and achieve the effect of improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

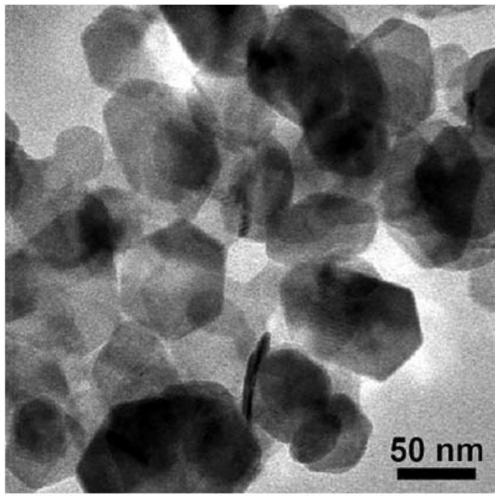

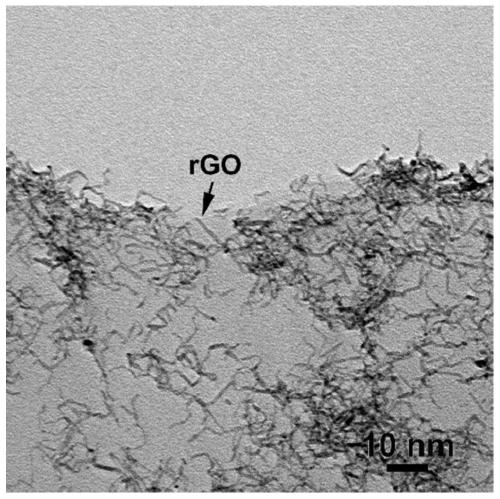

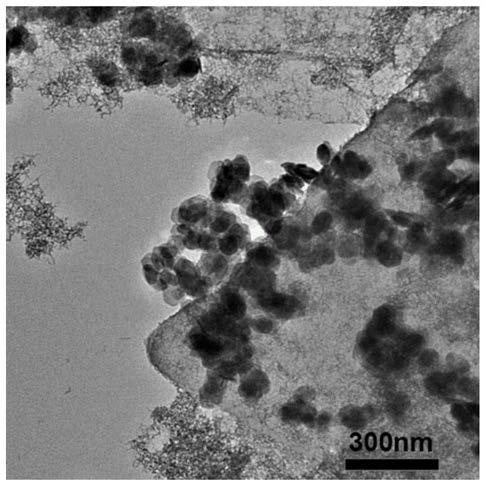

[0026] Specific Embodiment 1: The preparation method of the tin disulfide / graphene / tin dioxide ternary composite gas-sensitive material used for the nitrogen dioxide gas sensor in this embodiment is carried out according to the following steps:

[0027] 1. SnS 2 Preparation of nanosheets: under the protection of an inert atmosphere, add tin tetrachloride pentahydrate, oleic acid and octadecene to a three-necked bottle, the ratio of tin tetrachloride pentahydrate, oleic acid and octadecene is 0.37g: 1ml: 2ml, stir and remove oxygen and water at 100°C for 1 hour, then raise the temperature to 280°C at a heating rate of 6°C / min, add 5ml of sulfur oleylamine solution, the concentration of sulfur in the sulfur oleylamine solution is 0.2mmol / ml, react at a constant temperature of 280°C for 30 minutes, after the reaction, wash with ethanol and cyclohexane centrifugally, collect the product by centrifugal and disperse it in water, add dilute hydrochloric acid, adjust the pH value to ...

specific Embodiment approach 2

[0031] Specific embodiment two: the difference between this embodiment and specific embodiment one is that dilute hydrochloric acid is used in step one to adjust SnS 2 The ethanol solution has a pH of 3. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0032] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that in step two, ether is added each time, SnS 2 The volume ratio of aqueous solution to ether is 1:2. Others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com