Preparation method for KL molecular sieve catalyst and application of KL molecular sieve catalyst

A technology of molecular sieve and catalyst, which is applied in the field of preparation of KL molecular sieve catalyst, can solve problems such as poor catalytic performance, and achieve the effects of improving utilization rate, promoting diffusion, and high fructose conversion activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

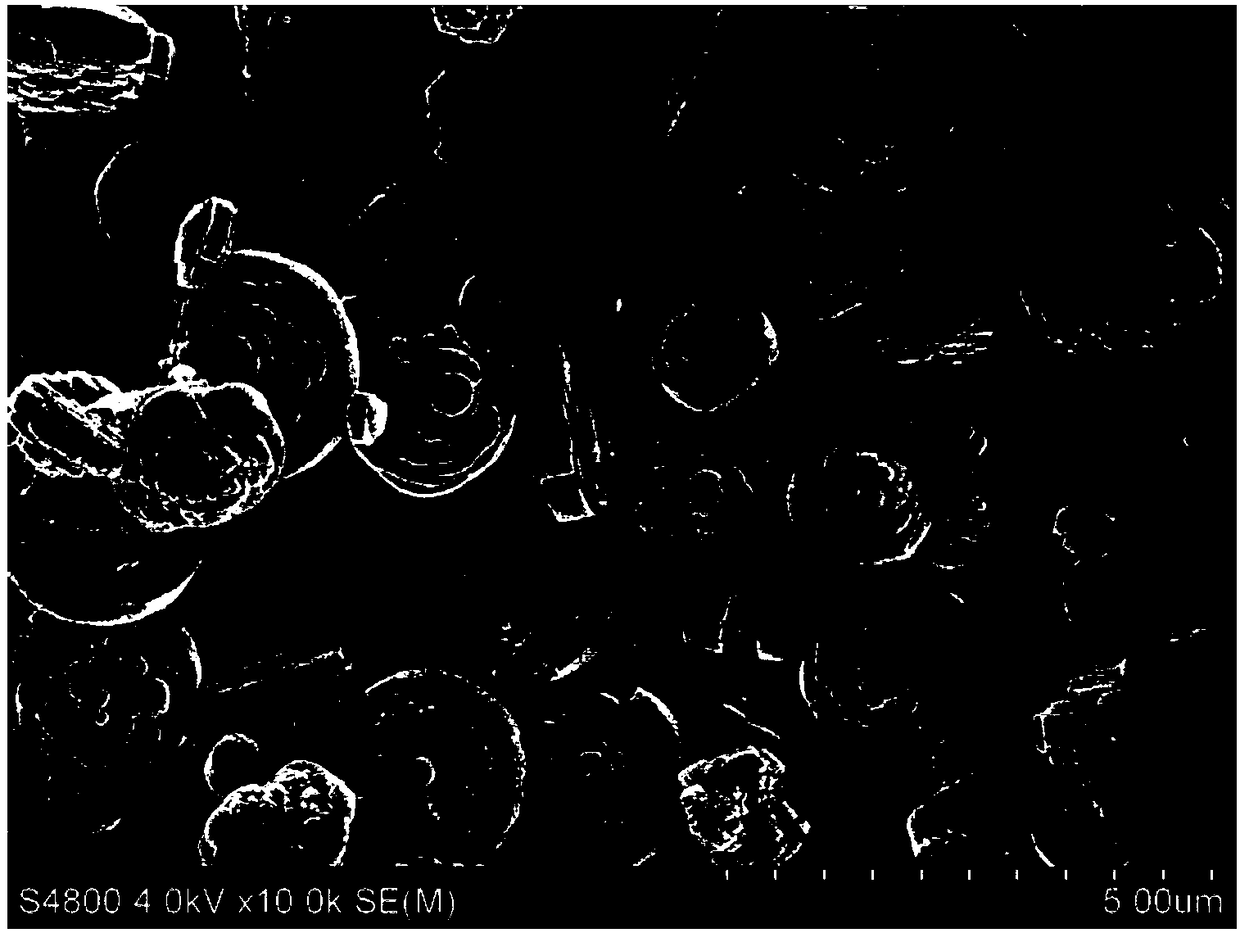

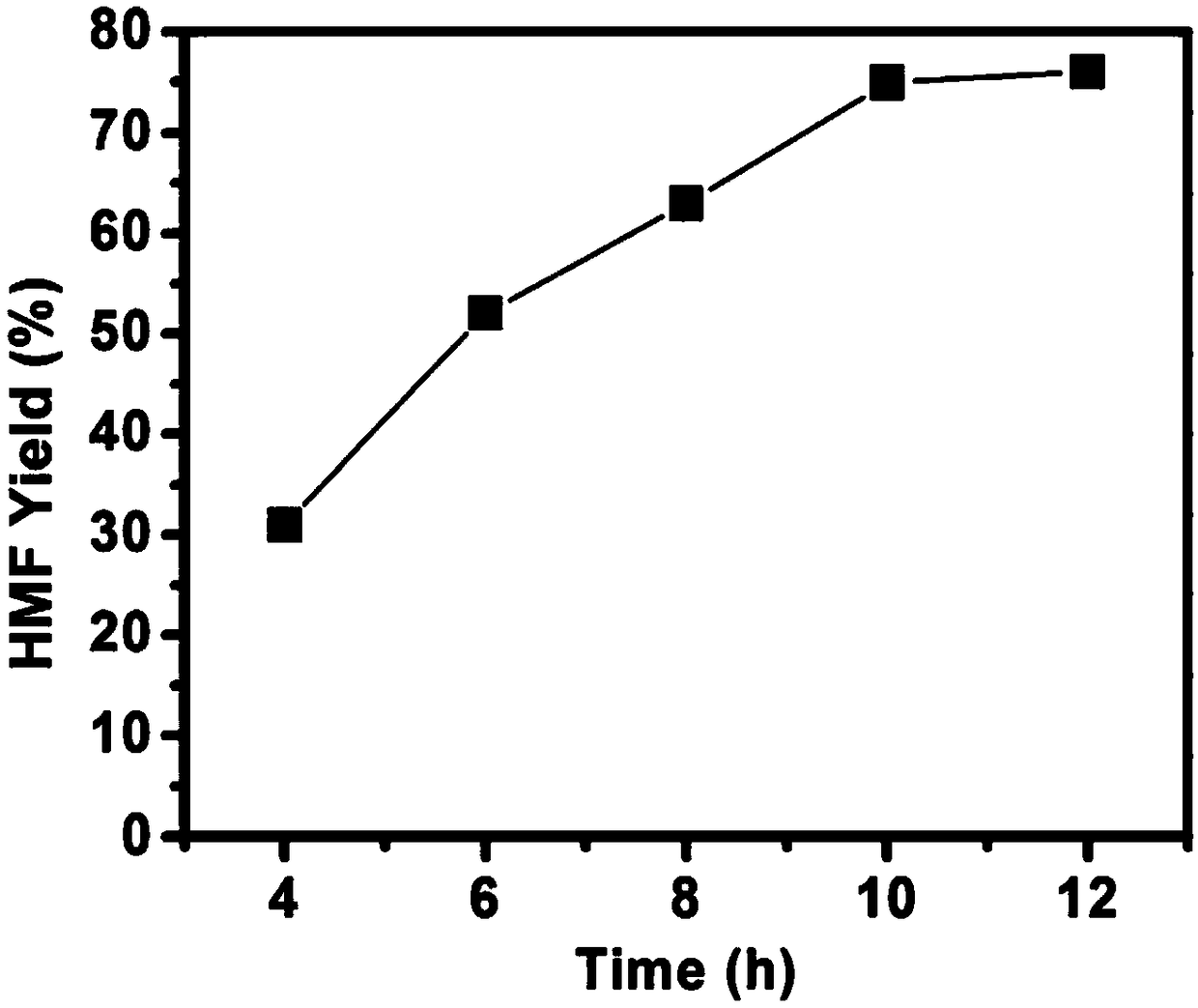

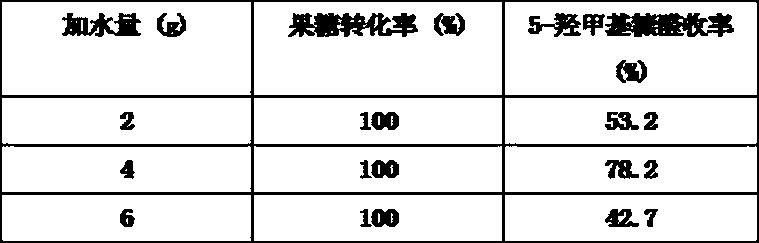

[0015] Add potassium hydroxide, sodium hydroxide, and sodium aluminate into deionized water in sequence, and stir at room temperature to form a clear solution A; add silica sol dropwise to solution A, and vigorously stir to form a uniform emulsion B. The moles of each material than K 2 O: Na 2 O: Al 2 o 3 : SiO 2 :H 2 O=5.4:5.7:1:10:500; After standing for 24 hours, the obtained emulsion B was transferred to a stainless steel hydrothermal kettle containing a polytetrafluoroethylene liner, and was heated in an oven at 140 o C for 24 hours of crystallization; the crystallized product was washed with deionized water until the filtrate was neutral, and the solid product was transferred to an oven at 110 o C for 12 hours, then placed in a muffle furnace at 300 o Roasting at C for 5 hours to obtain KL molecular sieves; measure 50 milliliters of 1 M ammonium chloride solution, pour it into a round bottom flask, and heat to 80 o C, then weigh 1 gram of KL molecular sieve and po...

Embodiment 2

[0017] Add potassium hydroxide, sodium hydroxide, and sodium aluminate into deionized water in sequence, and stir at room temperature to form a clear solution A; add silica sol dropwise to solution A, and vigorously stir to form a uniform emulsion B. The moles of each material than K 2 O: Na 2 O: Al 2 o 3 : SiO 2 :H 2 O=2.4:6.7:1:20:500; After standing for 24 hours, the obtained emulsion B was transferred to a stainless steel hydrothermal kettle containing a polytetrafluoroethylene liner, and was heated in an oven at 180 o C for 24 hours of crystallization; the crystallized product was washed with deionized water until the filtrate was neutral, and the solid product was transferred to an oven at 110 o C for 12 hours, then placed in a muffle furnace, 500 o Roasting at C for 5 hours to obtain KL molecular sieves; measure 50 milliliters of 1 M ammonium chloride solution, pour it into a round bottom flask, and heat to 80 o C, then weigh 1 gram of KL molecular sieve and pour...

Embodiment 3

[0019] Add potassium hydroxide, sodium hydroxide, and sodium aluminate into deionized water in sequence, and stir at room temperature to form a clear solution A; add silica sol dropwise to solution A, and vigorously stir to form a uniform emulsion B. The moles of each material than K 2 O: Na 2 O: Al 2 o 3 : SiO 2 :H 2 O=4.8:7.7:1:40:500; After standing for 24 hours, the obtained emulsion B was transferred to a stainless steel hydrothermal kettle containing a polytetrafluoroethylene liner, and was heated in an oven at 160 o C for 24 hours of crystallization; the crystallized product was washed with deionized water until the filtrate was neutral, and the solid product was transferred to an oven at 110 o C for 12 hours, then placed in a muffle furnace at 400 o Roasting at C for 5 hours to obtain KL molecular sieves; measure 50 milliliters of 1 M ammonium chloride solution, pour it into a round bottom flask, and heat to 80 o C, then weigh 1 gram of KL molecular sieve and po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com