Preparation method of powdery gypsum retarder and product obtained through method

A gypsum retarder, powdery technology, applied in the preparation of gypsum retarder, powdery gypsum retarder, powdery gypsum retarder preparation field, can solve the problem of protein gypsum retarder non-powder, The adaptability of different gypsums is quite different, and it is inconvenient to add dry powder gypsum products to achieve the effect of shortening the difference between initial setting time and final setting time, mild conditions and high adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

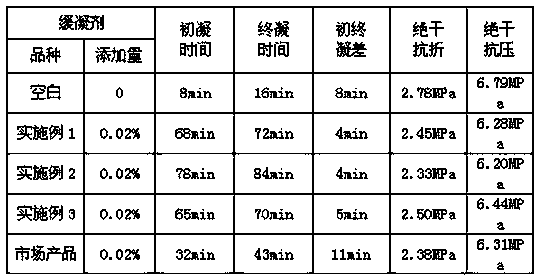

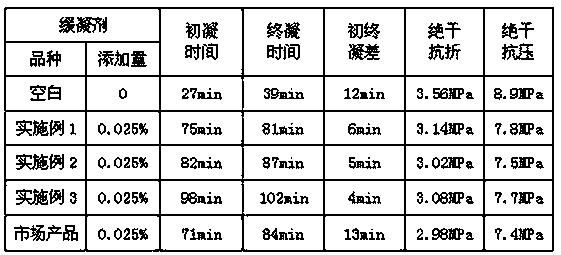

Examples

Embodiment 1

[0018] (1) Pretreatment of vegetable protein to form an intermediate product: a. Add 10% sodium hydroxide by weight to 55% tap water to form an alkaline solution; b. Add 28% soybean protein to the above alkali In the neutral solution, heat to 90 ° C, keep the temperature for 30 minutes to obtain the pretreatment solution; c, add 7% calcium sulfate dihydrate to the above pretreatment solution, stir evenly to form an intermediate product;

[0019] (2) Preparation of intermediate product powder: Mix the intermediate product prepared in step (1) with diatomaceous earth at a mass ratio of 3:1, then place it under high-speed stirring and mix evenly to form an intermediate product powder;

[0020] (3) Preparation of gypsum retarder: put the intermediate product powder obtained in step (2) with a weight component of 33%, 65% sodium gluconate, and 2% powdered polycarboxylate superplasticizer in a mixer Stir for 30 minutes to obtain powdered gypsum retarder.

Embodiment 2

[0022] (1) Pretreatment of vegetable protein to form an intermediate product: a. Add 15% sodium hydroxide by weight to 45% tap water to form an alkaline solution; b. Add 30% peanut protein to the above alkali In the neutral solution, heat to 90 ° C, keep the temperature for 30 minutes to obtain the pretreatment solution; c, add 10% calcium sulfate dihydrate to the above pretreatment solution, stir evenly to form an intermediate product;

[0023] (2) Preparation of intermediate product powder: Mix the intermediate product prepared in step (1) with diatomaceous earth at a mass ratio of 3:1, then place it under high-speed stirring and mix evenly to form an intermediate product powder;

[0024] (3) Preparation of gypsum retarder: Put the intermediate product powder obtained in step (2) with 20% by weight component, 79% tartaric acid, and 1% powdered polycarboxylate superplasticizer in a mixer and stir for 30 minutes , to obtain powdered gypsum retarder.

Embodiment 3

[0026] (1) Pretreatment of vegetable protein to form an intermediate product: a. Add 12% sodium hydroxide by weight to 50% tap water to form an alkaline solution; b. Add 35% zein to the above alkali In the neutral solution, heat to 90 ° C, keep the temperature for 30 minutes to obtain the pretreatment solution; c, add 13% calcium sulfate dihydrate to the above pretreatment solution, stir evenly to form an intermediate product;

[0027] (2) Preparation of intermediate product powder: mix the intermediate product prepared in step (1) with precipitated silica at a mass ratio of 2:1, then place it under high-speed stirring and mix evenly to form an intermediate product powder;

[0028] (3) Preparation of gypsum retarder: put the intermediate product powder obtained in step (2) with 40% by weight component, 59% citric acid, and 1% powdered polycarboxylate superplasticizer in a mixer and stir After 30 minutes, the powdered gypsum retarder is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com