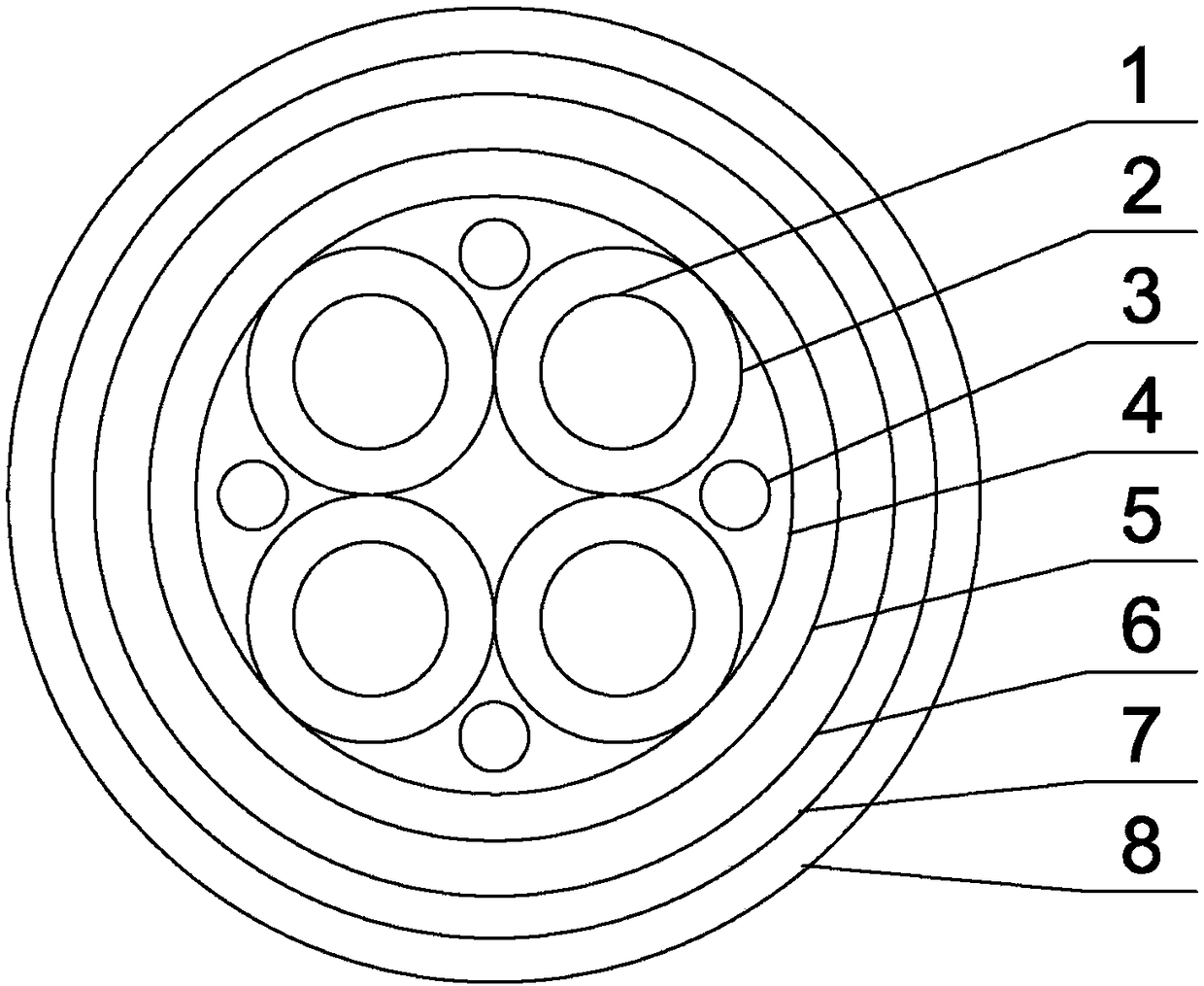

Special anti-aging cable for low wind speed wind-driven generator set

A technology for generating sets and special cables, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of unstable system operation, unstable wind force, unstable wind direction, etc., to improve anti-interference performance, low cost, and stable quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] Preferably, the preparation method of aging-resistant cable material comprises the following steps: (1): 15-30 parts of nitrile rubber, 8-16 parts of polyether ketone, 55-70 parts of nano-silica, antistatic Add 2-6 parts of chlorinated paraffin, 3-7 parts of sepiolite powder, and 2-6 parts of molybdenum disulfide into the high-speed mixer and mix them evenly; (2): Add 1.5-3.5 parts of chlorinated paraffin into the high-speed mixer 1-4 parts of maleic anhydride, 1-4 parts of phosphite, 2-7 parts of porous powder quartz, 10-20 parts of kapok fiber, 0.5-1.2 parts of disproportionated rosin, 1-4 parts of succinic acid and mix evenly; (3): Mix the material prepared in (2) in an internal mixer at a temperature of 87-95°C for 8-10 minutes; (4): Then mix the material in an open mixer, and then press it sliced, cut, and prepared as an aging-resistant cable material.

[0023] Preferably, the insulating layer is made of nanometer ethylene-propylene rubber mixture. The insulating...

Embodiment 1

[0024] Example 1: The aging-resistant cable material is composed of the following raw materials in parts by weight: 15 parts of nitrile rubber, 8 parts of polyether ketone, 3.5 parts of chlorinated paraffin, 65 parts of nano-silica, 1 part of maleic anhydride, phosphite 1 part, 7 parts of porous powder quartz, 6 parts of antistatic agent, 3 parts of sepiolite powder, 2 parts of molybdenum disulfide, 10 parts of kapok fiber, 1.2 parts of disproportionated rosin, 3 parts of succinic acid.

[0025] The preparation method is as follows: (1): Take 15 parts of nitrile rubber, 8 parts of polyether ketone, 65 parts of nano silicon dioxide, 6 parts of antistatic agent, 3 parts of sepiolite powder, and 2 parts of molybdenum disulfide respectively by weight. Put it into a high-speed mixer and mix it evenly; (2): Add 3.5 parts of chlorinated paraffin, 1 part of maleic anhydride, 1 part of phosphite, 7 parts of porous powder quartz, and 10 parts of kapok fiber into the high-speed mixer , 1...

Embodiment 2

[0026]Embodiment 2: The aging-resistant cable material is composed of the following raw materials in parts by weight: 20 parts of nitrile rubber, 10 parts of polyether ketone, 2.5 parts of chlorinated paraffin, 60 parts of nano-silica, 2 parts of maleic anhydride, phosphite 2 parts, porous powder quartz 5 parts, antistatic agent 4 parts, sepiolite powder 5 parts, molybdenum disulfide 4 parts, kapok fiber 15 parts, disproportionated rosin 0.8 parts, succinic acid 2 parts.

[0027] The preparation method is as follows: (1): Take 20 parts of nitrile rubber, 10 parts of polyether ketone, 60 parts of nano silicon dioxide, 4 parts of antistatic agent, 5 parts of sepiolite powder and 4 parts of molybdenum disulfide respectively by weight. Put it into a high-speed mixer and mix it evenly; (2): Add 2.5 parts of chlorinated paraffin, 2 parts of maleic anhydride, 2 parts of phosphite, 5 parts of porous powder quartz, and 15 parts of kapok fiber into the high-speed mixer , 0.8 parts of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com