Separation method of proteins

A separation method and protein technology, which is applied in the field of protein separation and analysis, can solve the problems of less research and development of stationary phases, and achieve the effects of high column efficiency, wide application range, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

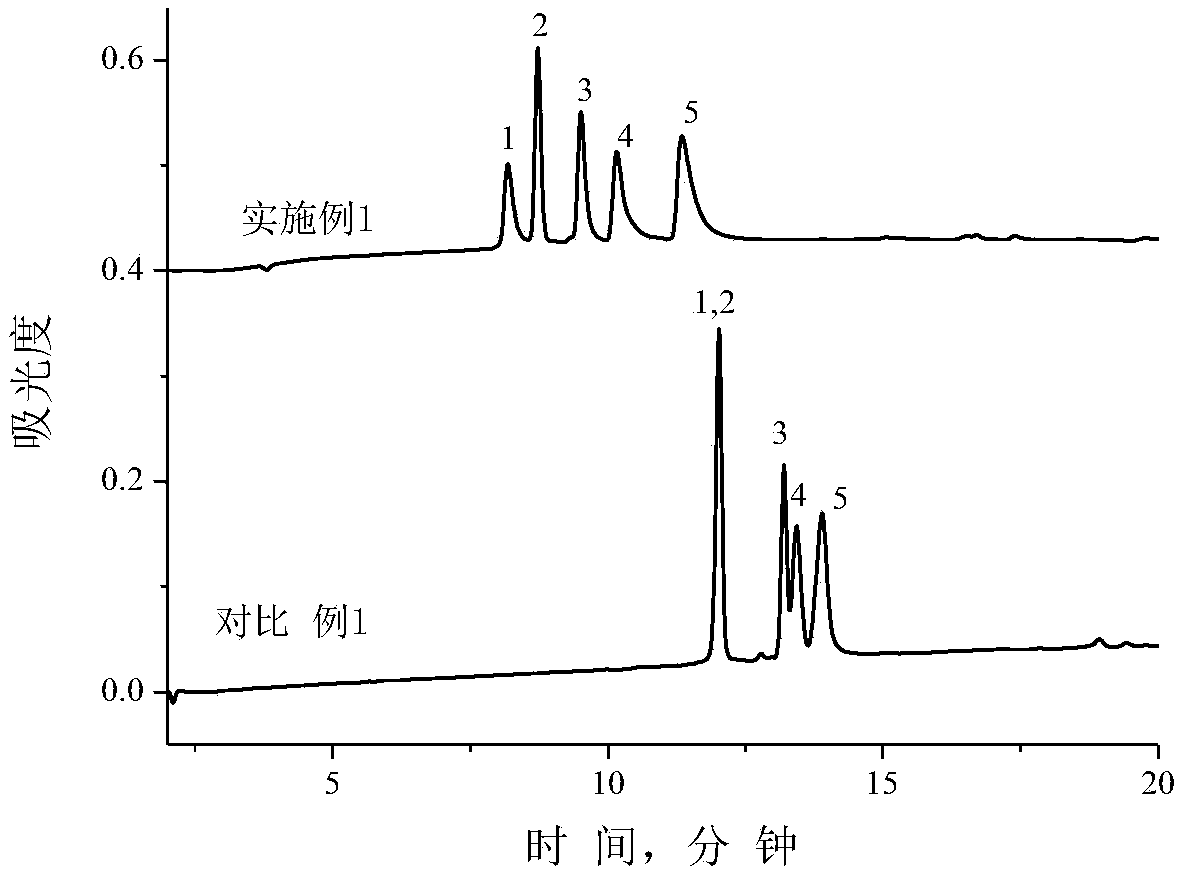

[0032] Take insulin (1), isoelectric point 5.3; cytochrome C (2), isoelectric point 10.7; lysozyme (3), isoelectric point 11.0; transferrin (4), isoelectric point 5.3; bovine serum albumin (5), the standard substance of isoelectric point 4.8, be dissolved in the trifluoroacetic acid aqueous solution of 0.1% volume concentration respectively, prepare the solution that concentration is 5mg / mL, take every kind of protein solution certain amount and mix and be mixed with protein mixed solution, carry out The sample volume is 5 μL. The non-polar group of the stationary phase is n-octane, and the structure of the polar group is as follows:

[0033]

[0034] The column specification is 4.6mm×150mm I.D., 5μm, pore size

[0035] The chromatographic separation conditions on the stationary phase are as follows: column temperature 30°C, flow rate 1mL / min; mobile phase aqueous phase solution is 0.1% volume concentration of trifluoroacetic acid aqueous solution, organic phase is 0.1% ...

Embodiment 2

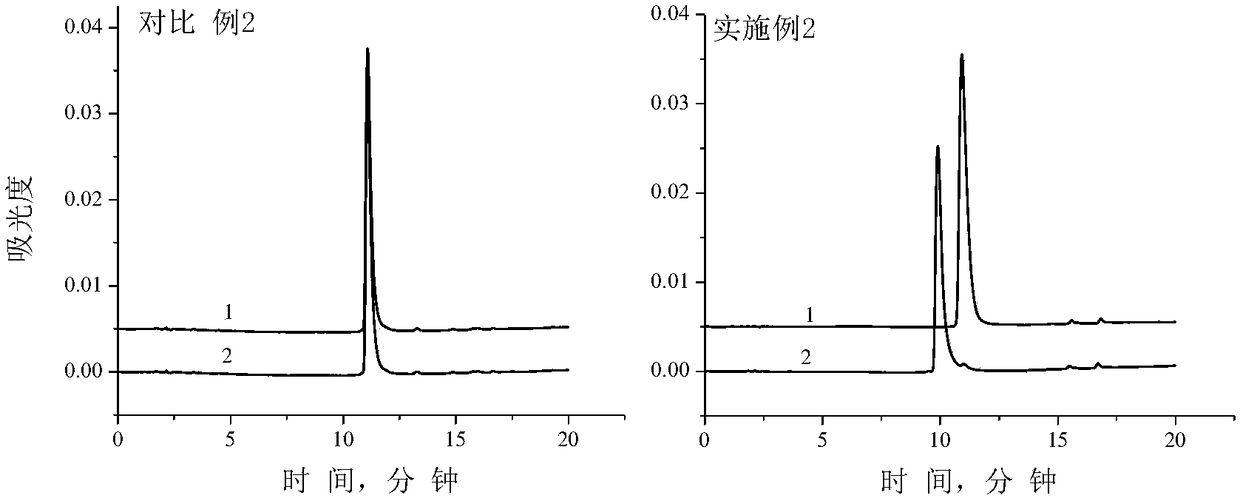

[0040]Standards of carbonic anhydrase (1), isoelectric point 5.9 and myoglobin (2), isoelectric point 7.0 were respectively dissolved in 10mM ammonium formate aqueous solution, the concentration was 5mg / mL, and the injection volume was 5μL; the structure and implementation of chromatographic packing The same as Example 1, the column specification is 4.6mm×150mm I.D., 5μm, pore size The column temperature is 30°C, the flow rate is 1mL / min; the mobile phase A is ammonium formate aqueous solution, the pH value is 3.0, and the isocratic 10mM; the B phase is acetonitrile, and the B phase gradient is 10%-60% volume concentration, 0-20min; Detector, detection wavelength 280nm;

Embodiment 3

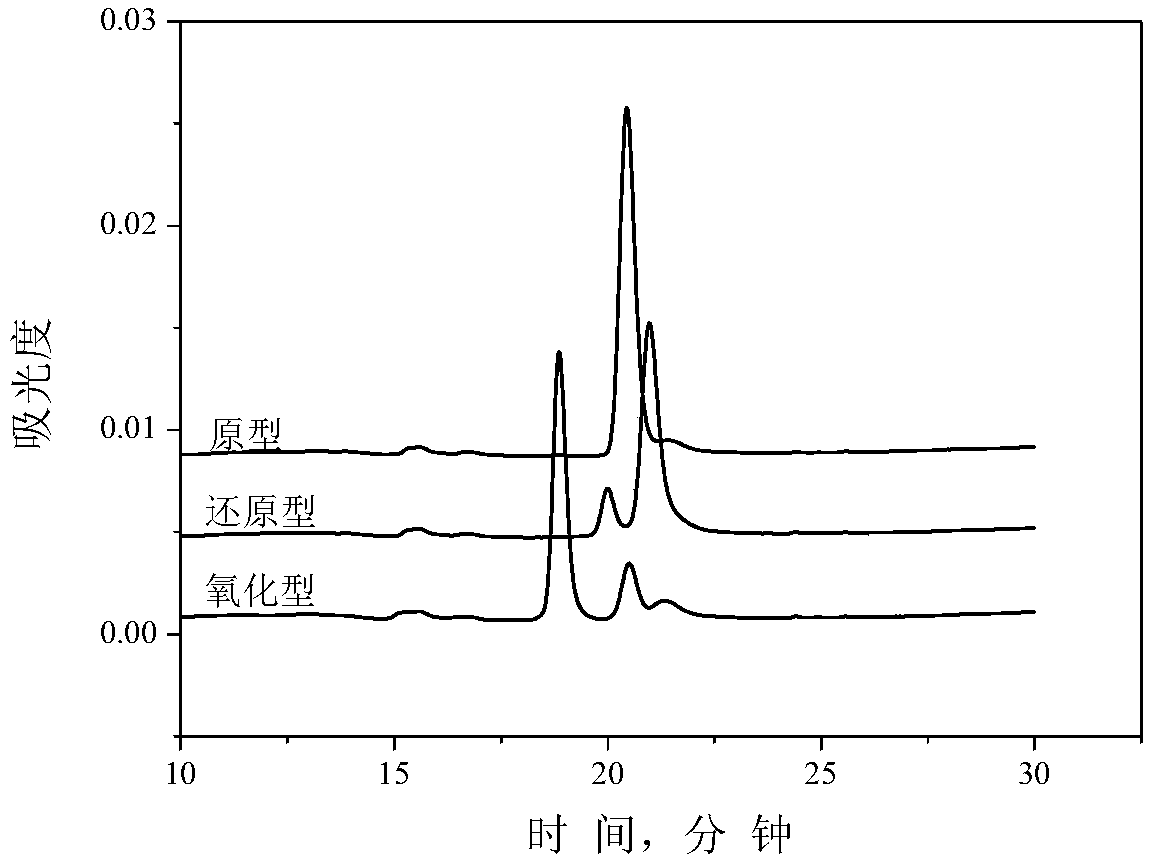

[0044] Recombinant human growth hormone (r-hGH) was dissolved in pure water to prepare a mother solution (prototype) with a concentration of 2 mg / mL, and 100 μL of the mother solution was added to 10 μL of 100 mM dithiothreitol and incubated at 30 ° C for 60 minutes to obtain reduced r-hGH (reduced form), take another 100 μL mother solution and add 5 μL hydrogen peroxide (30% v / v) to incubate at 30°C for 60 minutes, then add an appropriate amount of methionine to terminate the reaction to obtain oxidized r-hGH (oxidized form), injection volume 5 μL . The chromatographic packing structure is the same as in Example 1, and the chromatographic column specification is 4.6mm×150mmI.D., 5μm, and the aperture Column temperature is 30°C, flow rate is 1mL / min; mobile phase A is ammonium formate aqueous solution, pH value is 3.0, isocratic 50mM; B phase is acetonitrile, gradient condition is B phase volume concentration 20%-75%, 0-30min, The pH value is 3.0; UV detector, detection wave...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com