Preparation method of antistatic non-woven fabric

A non-woven fabric and antistatic technology, applied in textiles and papermaking, cellulose/protein conjugated artificial filaments, conjugated synthetic polymer artificial filaments, etc. Problems such as fuzzing, to achieve the effect of improving antistatic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

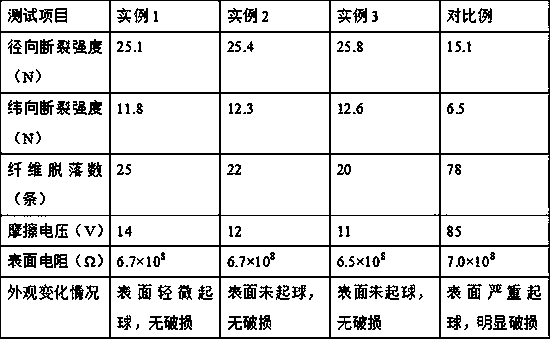

Examples

example 1

[0026] Put 20g of PVA-co-PE nanofiber masterbatch and 70 parts of cellulose acetate butyl masterbatch in a vacuum drying oven, heat up to 100°C, preheat for 1 hour, and put the preheated PVA-co-PE nanofiber masterbatch The spinning raw material is obtained by mixing the cellulose acetate butyl masterbatch and the spinning raw material, and the spinning raw material is placed in a twin-screw extruder, and the temperature of the head is controlled at 200°C, the twin-screw speed is 100r / min, and the feeding speed is 12g / min. min, and the drafting ratio in the later stage is 25 times, and extruded by a twin-screw extruder to obtain a composite fiber with a diameter of 0.8mm; the composite fiber is wound on a stainless steel support, and then the stainless steel support is placed in a Soxhlet extraction with acetone In the container, control the composite fiber on the stainless steel support to be completely immersed in acetone, heat the water bath to 80°C, and keep it warm for 20 h...

example 2

[0028] Put 22g of PVA-co-PE nanofiber masterbatch and 75 parts of cellulose acetate butyl masterbatch in a vacuum drying oven, heat up to 110°C, preheat for 1.5h, and put the preheated PVA-co-PE nanofiber The masterbatch is mixed with cellulose acetate butyl masterbatch to obtain the spinning raw material, and the spinning raw material is placed in a twin-screw extruder, the temperature of the head is controlled at 210°C, the twin-screw speed is 110r / min, and the feeding speed is 14g / min, the drafting ratio in the later stage is 27 times, and extruded by a twin-screw extruder to obtain a composite fiber with a diameter of 0.9mm; the composite fiber is wound on a stainless steel support, and then the stainless steel support is placed in a Soxhlet with acetone In the extractor, control the composite fiber on the stainless steel support to be completely immersed in acetone, raise the temperature of the water bath to 82°C, and keep it warm for 21 hours to obtain PVA-co-PE nanofibe...

example 3

[0030] Put 25g of PVA-co-PE nanofiber masterbatch and 80 parts of cellulose acetate butyl masterbatch in a vacuum drying oven, heat up to 120°C, preheat for 2 hours, and put the preheated PVA-co-PE nanofiber masterbatch The spinning raw material is obtained by mixing the cellulose acetate butyl masterbatch and the spinning raw material, and the spinning raw material is placed in a twin-screw extruder, and the temperature of the head is controlled at 220°C, the twin-screw speed is 120r / min, and the feeding speed is 15g / min. min, and the drafting ratio in the later stage is 30 times, and extruded by a twin-screw extruder to obtain a composite fiber with a diameter of 1.0mm; the composite fiber is wound on a stainless steel support, and then the stainless steel support is placed in a Soxhlet extraction with acetone In the container, control the composite fiber on the stainless steel support to be completely immersed in acetone, raise the temperature of the water bath to 85 °C, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com