A method for preparing carbon-coated lithium iron phosphate material and its application

A technology of carbon-coated lithium iron phosphate and phosphoric acid, applied in the direction of phosphate, phosphorus oxyacid, chemical instruments and methods, etc., to achieve the effects of environmental friendliness, improved electrochemical performance, and low requirements for experimental equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

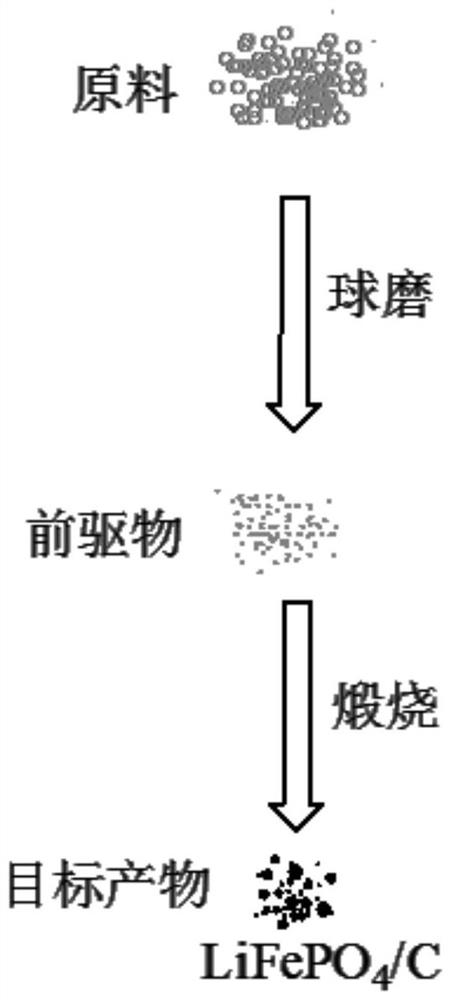

[0051] Example 1 Sample 1 # preparation

[0052] Pretreatment of raw materials: Accurately weigh 3.784g of melamine, 1.529g of lithium oxalate, and 2.396g of ferric oxide with an electronic balance, and grind them in a mortar to obtain red powder. Measure 2.05mL of phosphoric acid, and then It is added to the previous mixture, and it is ground until it becomes a homogeneous, sticky powder.

[0053] Ball milling process: vacuum-dry the wet powder at 80°C for 5 hours, crush the powder with a mortar and then ball-mill at 600 rpm for 10 hours after drying to obtain the precursor.

[0054] Calcination process: The obtained precursor was placed in a tube furnace and filled with argon gas, first heated to 350°C at a heating rate of 4°C / min, held for 4 hours, and then heated to 700°C at a heating rate of 3°C / min for 12 hours. After cooling to room temperature, the product was taken out and ground to obtain black powder. The black powder is the final product prepared by the present ...

Embodiment 2

[0055] Example 2 Sample 2 # ~9 # preparation

[0056] Sample 2 # ~9 # The preparation process and the raw materials used are the same as the sample 1 in Example 1. # The preparation differs in that the conditions during the ball milling process and the calcination process are varied. The relationship between sample numbers and preparation conditions is shown in Table 1.

[0057] Table 1

[0058]

[0059]

Embodiment 3

[0060] Structural Characterization of Example 3 Samples

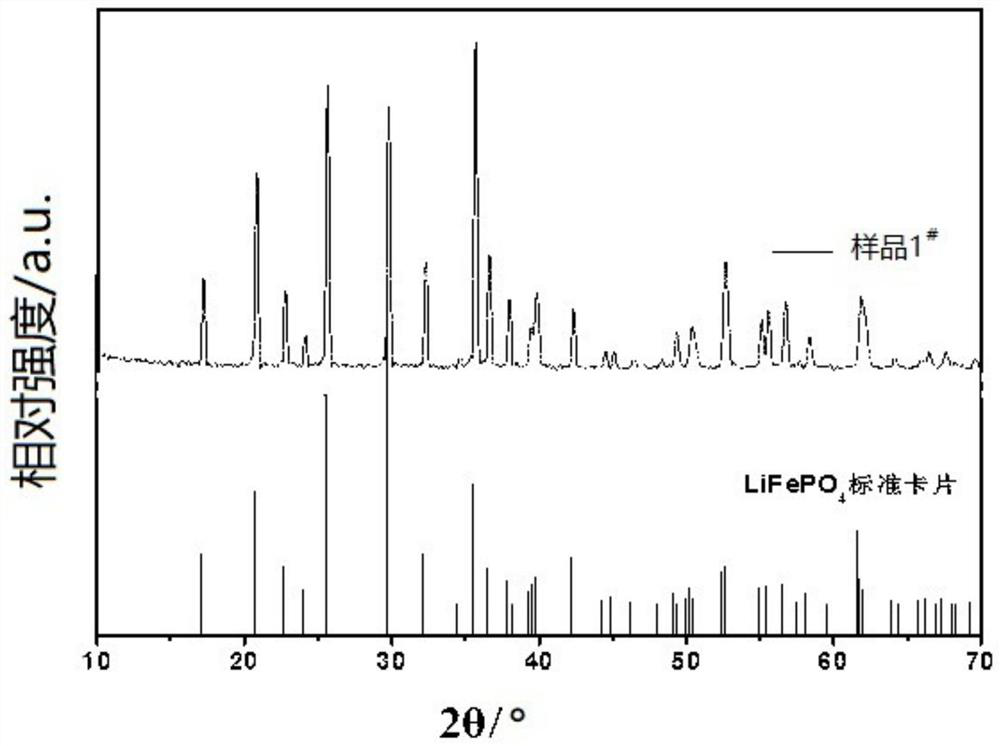

[0061] for sample 1 # ~9 # X-ray powder diffraction phase analysis (XRD) was carried out. The results show that sample 1 prepared in Examples 1 and 2 # ~9 # All samples are of high purity and high crystallinity.

[0062] Take sample 1 # is a typical representative, and its XRD pattern is similar to that of LiFePO. 4 Comparison of standard spectra such as image 3 shown. Depend on image 3 It can be seen that sample 1 # The XRD diffraction patterns of the obtained samples are highly consistent, which proves that the obtained samples are samples of high purity and high crystallinity. Sample 2 # ~Sample 9 # XRD pattern of sample 1 # Similarly, the peak position was basically unchanged, and the peak intensity varied in the range of ±5% with the synthesis conditions.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com