Nitrogen-doped graphene supported iron-based catalyst as well as preparation method and application thereof

A technology of nitrogen-doped graphene and iron-based catalysts, which is applied in the preparation of amino compounds, amino-hydroxyl compounds, chemical instruments and methods, etc., and can solve the problems of harsh reaction conditions of iron-based catalysts, unfavorable large-scale application of catalysts, and reaction time Long and other problems, to achieve the effect of simple preparation method, high activity, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation of embodiment 1 catalyst

[0038] Graphene oxide was prepared by the improved Hummers method, including pre-oxidation and oxidation of graphite. Pre-oxidation: add 8.4g K to a 500mL three-neck flask 2 S 2 o 7 , 10g graphite powder, 8.4g P 2 o 5 , and under the condition of stirring, 40mL of concentrated sulfuric acid was added into the flask, heated and stirred, condensed and refluxed, the temperature was controlled at 80°C, and the reaction was ended after 4.5h. After the temperature of the solution is cooled to room temperature, slowly add 250 mL of deionized ice water, and control the temperature not to exceed 80 °C during the addition process. After standing still for a period of time, carry out suction filtration, wash with deionized water until the filtrate is neutral, and obtain the pre-oxidized product after being drained. Oxidation: Add the pre-oxidized product into a 1000mL three-neck flask, pour 230mL of concentrated sulfuric acid into i...

Embodiment 2

[0046] Step 1. Take 100 mL of the graphene oxide dispersion prepared in Example 1, add 10.0 g of urea, stir and sonicate for 2 hours, transfer the mixed solution to a 300 mL polytetrafluoroethylene-lined hydrothermal kettle, and heat at 160 ° C. Reaction 3h;

[0047] Step 2. Suction filter the reaction product obtained in Step 1, and fully wash it with deionized water until the pH value is about 7; dry the washed solid product in vacuum at 100° C. overnight to obtain nitrogen-doped graphene;

[0048] Step 3, dissolving 0.093g of ferrous acetate in 20mL of absolute ethanol, adding 1g of nitrogen-doped graphene obtained in step 2 (iron load 3wt%), and stirring at 60°C for 15h;

[0049] Step 4, after cooling to room temperature, vacuum rotary evaporation, after removing the solvent ethanol, vacuum drying at 60°C for 12 hours, and grinding the obtained solid into powder;

[0050] Step 5, the powder solid of step 4 gained is placed in tube furnace, under N 2 Under protection, it ...

Embodiment 3

[0052] The preparation process of the catalyst is the same as that in Example 2, except that in Step 5, it is pyrolyzed at 1000° C. for 2 hours.

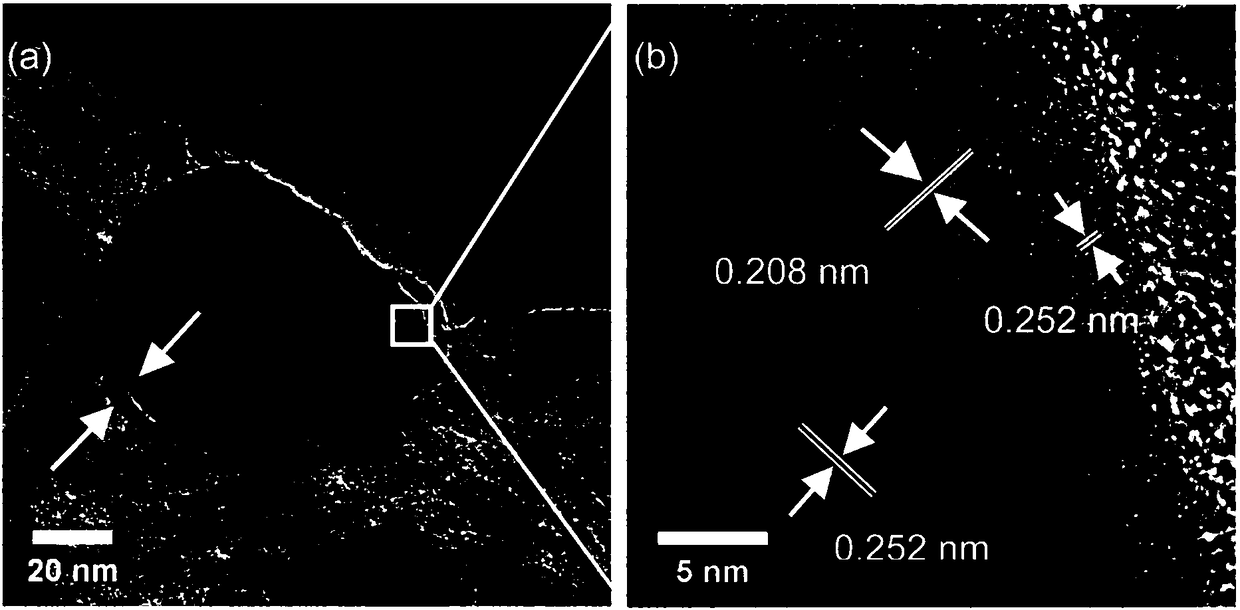

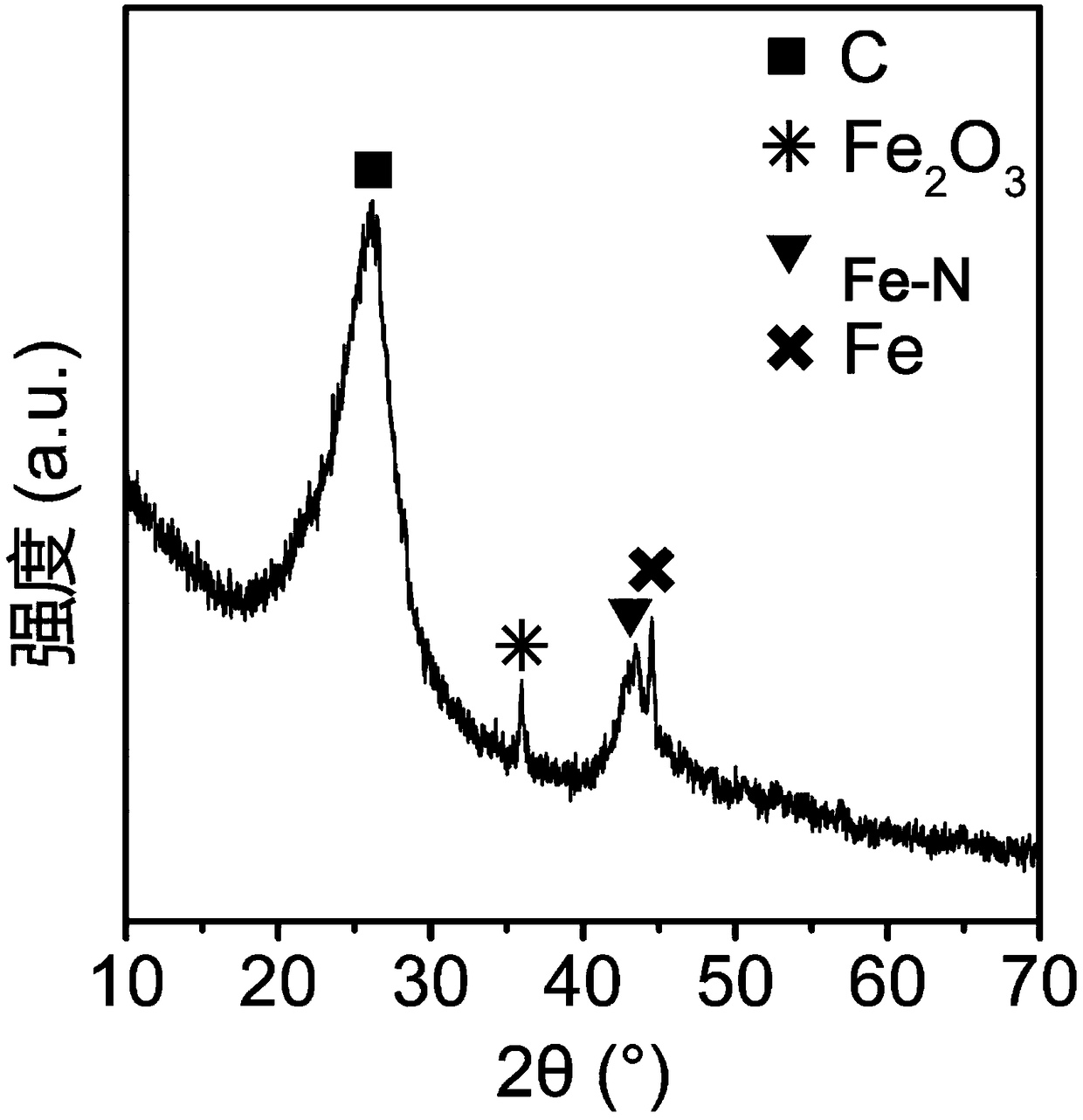

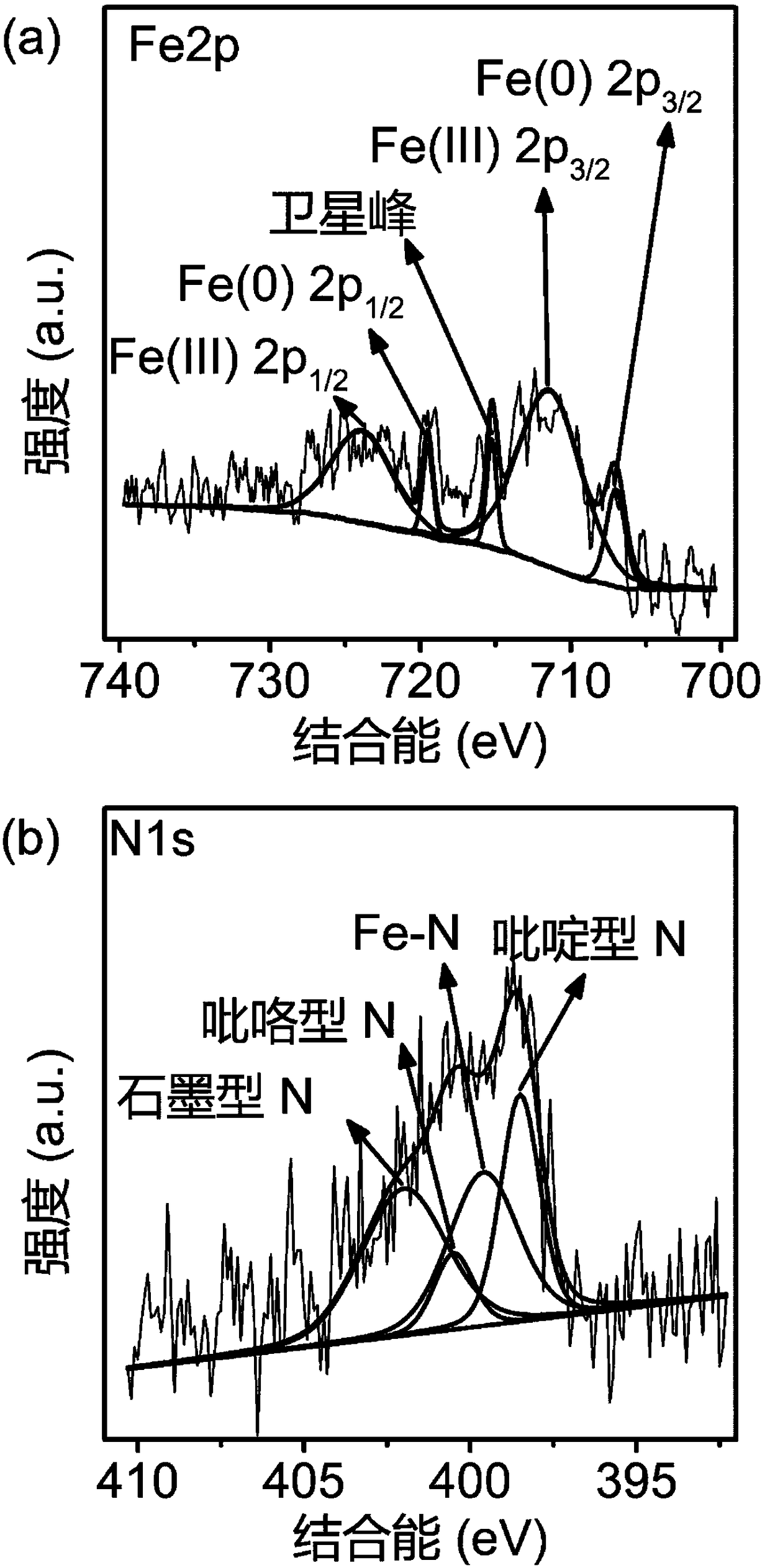

[0053] Compared with the nitrogen-doped graphene-supported iron-based catalyst prepared in Example 1 above, in Example 2, the catalyst prepared by pyrolysis at 600 ° C did not form a structure of nitrogen-doped graphene-wrapped iron metal particles, with There are fewer Fe-N active sites; while in Example 3, the nitrogen-doped graphene layer covering the iron metal particles in the catalyst prepared by pyrolysis at 1000°C is thicker, which shields the Fe-N active sites. Therefore, compared with the nitrogen-doped graphene-supported iron-based catalyst obtained in Example 1, the nitrogen-doped graphene-supported iron-based catalysts obtained in Examples 2 and 3 respectively have poorer activities in the catalytic hydrogenation of nitrobenzene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com