Modified nano sio 2 Particles, methods for their preparation, and nanofiber membranes, gel electrolytes, and lithium metal batteries comprising the same

A technology of gel electrolyte and nanofiber membrane, applied in its preparation method and nanofiber membrane containing it, gel electrolyte and lithium metal battery, and modified nano-SiO2 particles, which can solve the problems of small liquid absorption, battery short circuit, Problems such as high crystallinity, to achieve large porosity and gas permeability, improve ionic conductivity, and improve the effect of interaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] This embodiment provides a modified nano-SiO 2 particles, including nano-SiO 2 Particles and grafting on nano-SiO 2 Ionic liquids on particles;

[0080] Wherein, the cation of the ionic liquid is 1-propyl(trimethoxy)silane-1-methylpiperidinium, and the anion of the ionic liquid is bistrifluoromethylsulfonimide anion.

[0081] This embodiment modified nano-SiO 2 Particles are prepared as follows:

[0082] (1) Dissolve N-methylpiperidine and 3-chloropropyltrimethoxysilane (molar ratio 1:1.1) in DMF respectively, and add N-methylpiperidine solution dropwise under nitrogen protection environment In 3-chloropropyltrimethoxysilane solution, stirred and reacted at 80°C for 1 day, the reaction product was washed, rotary evaporated and dried to obtain 1-propyl(trimethoxy)silane-1-methylpiperidinium Chloride (PPCl);

[0083] (2) PPCl obtained in step (1) is dissolved in water, and SiO is added dropwise 2 Colloid (particle size 20-100nm), stir evenly, react at 100°C for 12h...

Embodiment 2

[0086] This embodiment provides a modified nano-SiO 2 particles, including nano-SiO 2 Particles and grafting on nano-SiO 2 Ionic liquids on particles;

[0087] Wherein, the cation of the ionic liquid is 1-propyl(trimethoxy)silane-1-methylpiperidinium, and the anion of the ionic liquid is a bisfluorosulfonimide anion.

[0088] This embodiment modified nano-SiO 2 The preparation method of particles is as follows:

[0089] (1) Dissolve N-methylpiperidine and 3-chloropropyltrimethoxysilane (molar ratio 1:1.1) in DMF respectively, and add N-methylpiperidine solution dropwise under nitrogen protection environment In 3-chloropropyltrimethoxysilane solution, stirred and reacted at 75°C for 3 days, the reaction product was washed, rotary evaporated and dried to obtain 1-propyl(trimethoxy)silane-1-methylpiperidinium Chloride (PPCl);

[0090] (2) PPCl obtained in step (1) is dissolved in water, and SiO is added dropwise 2 Colloid (particle size 20-100nm), stir evenly, react at 70°...

Embodiment 3

[0093] This embodiment provides a modified nano-SiO 2 particles, including nano-SiO 2 Particles and grafting on nano-SiO 2 Ionic liquids on particles;

[0094] Wherein, the cation of the ionic liquid is 1-propyl(trimethoxy)silane-1-methylpiperidinium, and the anion of the ionic liquid is difluorooxalate borate anion.

[0095] This embodiment modified nano-SiO 2 The preparation method of particles is as follows:

[0096] (1) Dissolve N-methylpiperidine and 3-chloropropyltrimethoxysilane (molar ratio 1:1.1) in DMF respectively, and add N-methylpiperidine solution dropwise under nitrogen protection environment In 3-chloropropyltrimethoxysilane solution, stirred and reacted at 85°C for 1.5 days, the reaction product was washed, rotary evaporated and dried to obtain 1-propyl(trimethoxy)silane-1-methylpiperidinium Chloride (PPCl);

[0097] (2) PPCl obtained in step (1) is dissolved in water, and SiO is added dropwise 2 colloid (particle size 20-100nm), stir evenly, react at 9...

PUM

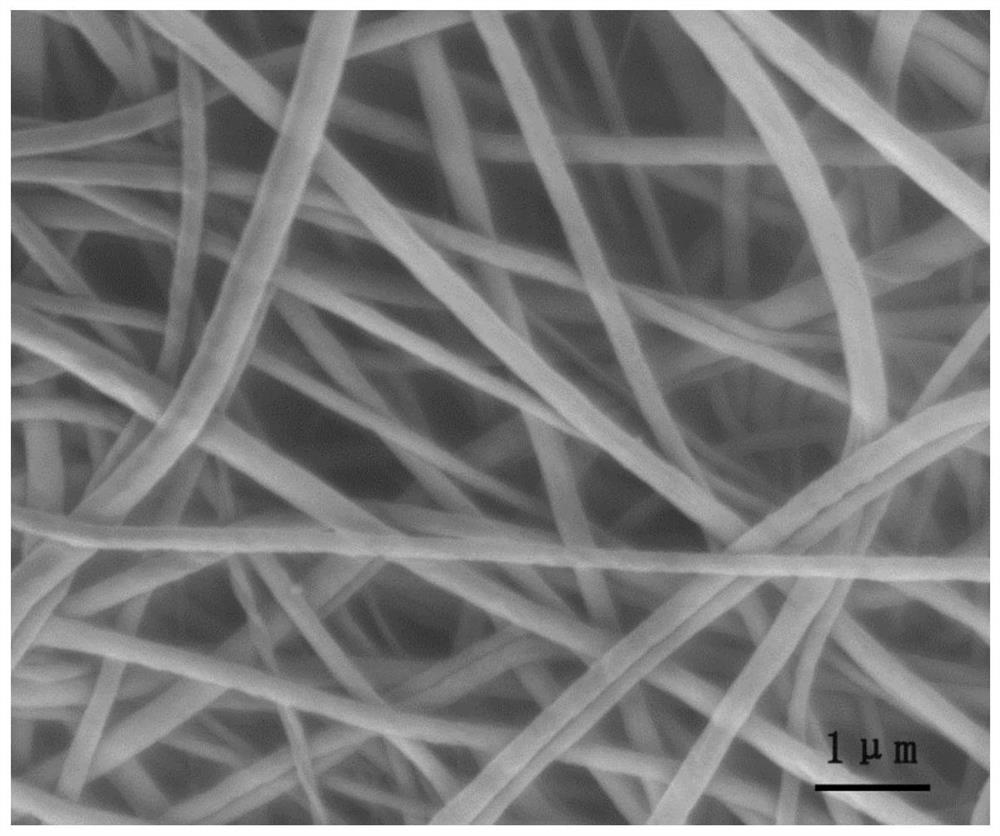

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com