Preparation method of environmentally friendly building adhesive

A kind of adhesive and construction technology, applied in the direction of shellac adhesive, rosin adhesive, polymer adhesive additive, etc., can solve the problems of harmfulness to human body, high formaldehyde content, non-environmental protection of materials, etc., and achieve good environmental protection , the amount of free formaldehyde is less, the effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

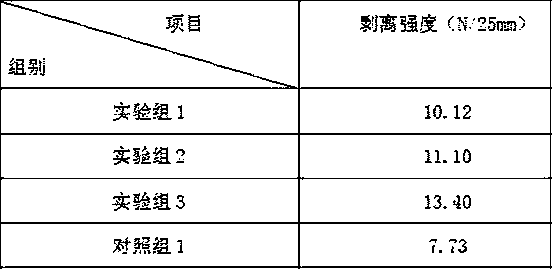

Examples

Embodiment 1

[0049] An environmentally friendly construction adhesive, comprising the following raw materials in parts by weight: 80 parts of rosin glyceride, 25 parts of shellac, 172 parts of terpene resin, 24 parts of turpentine, 4 parts of aluminum silicate powder, and 2 parts of white carbon black. Parts, 5 parts of zirconium hydrogen phosphate, 1 part of tannin, 2 parts of potassium pyrophosphate, 6 parts of ethanol, 10 parts of hydroxyethyl cellulose, 5 parts of gum arabic, 3 parts of potassium lactate, 2 parts of sodium lactate, 1 part of sodium diacetate , 6 parts of silicon carbide whiskers and 5 parts of butyl lactate.

[0050] A preparation method of environmental protection building adhesive includes the following steps:

[0051] 1) Pour 5 parts of Arabic gum and 25 parts of shellac into the stirring pot, heat and stir under pressure, heating temperature is 50℃, stirring speed is 20r / min, pressure is 50MPa, heating and stirring The time is 20min, and the viscous liquid is prepared,...

Embodiment 2

[0055] An environmentally friendly building adhesive, comprising the following raw materials in parts by weight: 97 parts of rosin glyceride, 32 parts of shellac, 186 parts of terpene resin, 57 parts of turpentine, 6 parts of aluminum silicate powder, 4 parts of white carbon black Parts, 7 parts of zirconium hydrogen phosphate, 3 parts of tannin, 4 parts of potassium pyrophosphate, 8 parts of ethanol, 12 parts of hydroxyethyl cellulose, 9 parts of gum arabic, 5 parts of potassium lactate, 4 parts of sodium lactate, 4 parts of sodium diacetate , 9 parts of silicon carbide whiskers and 8 parts of butyl lactate.

[0056] A preparation method of environmental protection building adhesive includes the following steps:

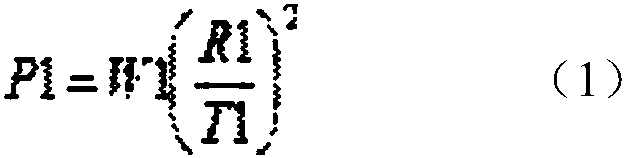

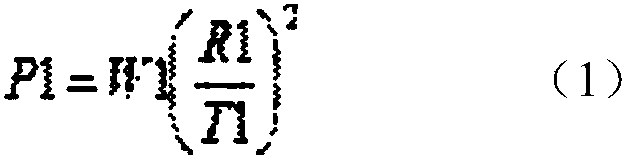

[0057] 1) Pour 9 parts of Arabic gum and 32 parts of shellac into the stirring pot, heat and stir under pressure, the heating temperature V1 is 60℃, the stirring speed R1 is 30r / min, the pressure P1 is 70MPa , The heating and stirring time T1 is 30min, and the viscous l...

Embodiment 3

[0064] An environmentally friendly building adhesive, comprising the following raw materials in parts by weight: 90 parts of rosin glyceride, 28 parts of shellac, 180 parts of terpene resin, 35 parts of turpentine, 5 parts of aluminum silicate powder, 3 parts of white carbon black Parts, 6 parts of zirconium hydrogen phosphate, 2 parts of tannin, 3 parts of potassium pyrophosphate, 7 parts of ethanol, 11 parts of hydroxyethyl cellulose, 7 parts of gum arabic, 4 parts of potassium lactate, 3 parts of sodium lactate, 2 parts of sodium diacetate , 8 parts of silicon carbide whiskers and 7 parts of butyl lactate.

[0065] A preparation method of environmental protection building adhesive includes the following steps:

[0066] 1) Pour 7 parts of Arabic gum and 28 parts of shellac into the stirring pot, heat and stir under pressure, heating temperature W1 is 55℃, stirring speed R1 is 25r / min, pressure P1 is 60MPa , The heating and stirring time T1 is 25min, and the viscous liquid is pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com