Grape seed oil and preparation method thereof

A technology of grape seed oil and grape seed powder, which is applied in the direction of fat oil/fat refining, edible oil/fat, fat oil/fat production, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

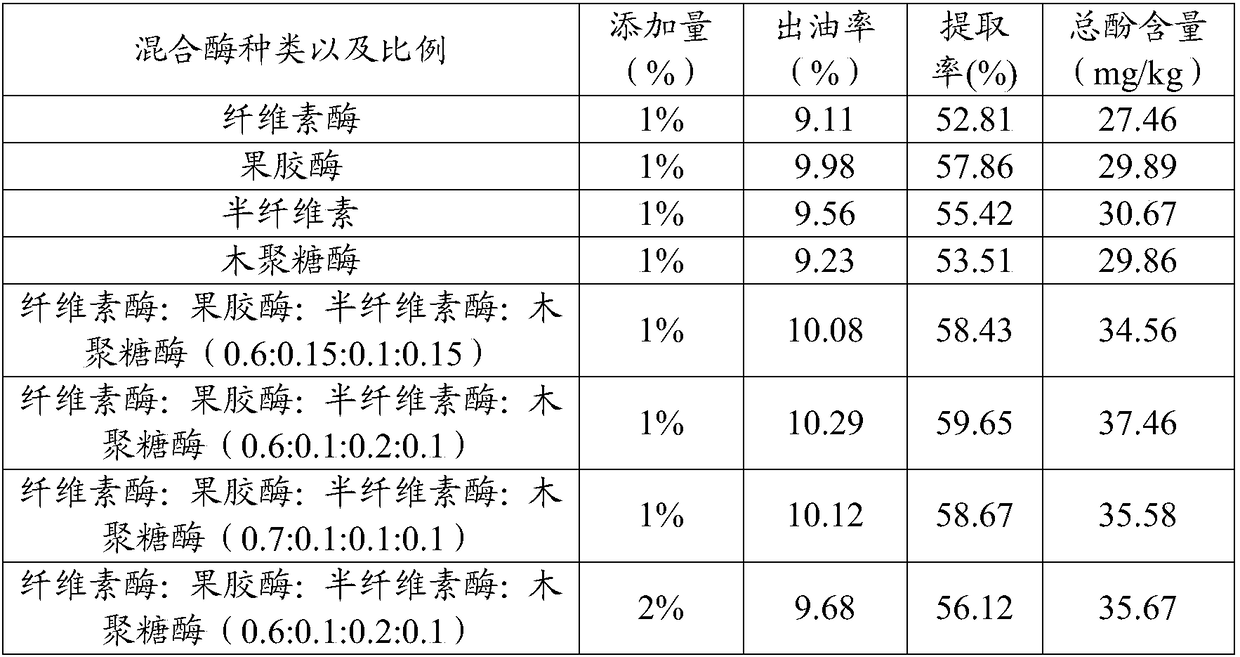

[0062] Embodiment 1. The influence of mixed enzyme types and additions on the extraction of grapeseed oil

[0063] (1) Grape seed pretreatment: The grape seeds are pulverized by a universal mill and passed through a 50-mesh sieve to obtain the raw material of grape seed powder. %, and the fiber content is 30.6%.

[0064] (2) Enzymatic hydrolysis with mixed enzymes: Mix distilled water and grape seed powder in a volume-to-mass ratio of 5 (mL): 1 (g) to obtain a slurry, add hydrochloric acid to adjust the pH of the slurry to 5, and add mixed enzymes for enzymatic hydrolysis. The hydrolysis reaction temperature was 50 °C, the enzymatic hydrolysis reaction time was 2 h, and the addition scheme of the mixed enzyme was shown in Table 1;

[0065] (3) Acid protease enzymatic hydrolysis: add hydrochloric acid to the slurry, adjust the pH to 4.5, and add acid protease for enzymatic hydrolysis, the addition amount is 0.1%, the enzymatic hydrolysis reaction temperature is 50 ℃, and the e...

Embodiment 2

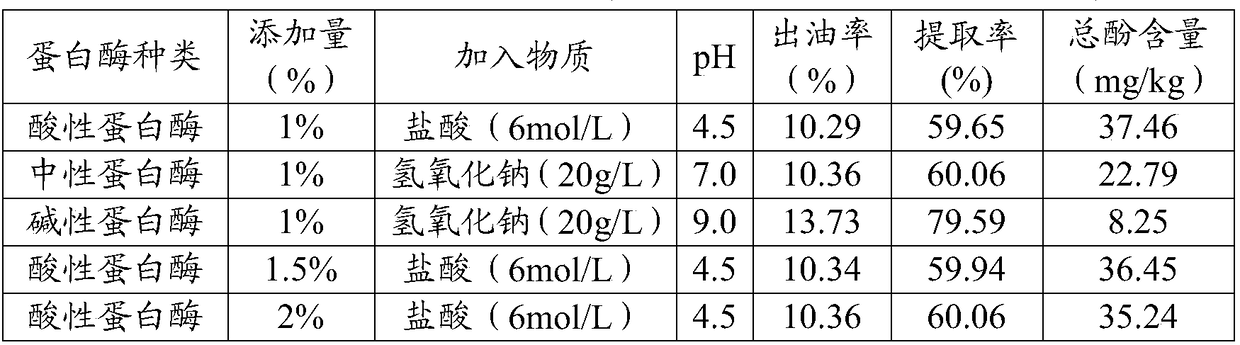

[0071] Example 2 Effects of protease types and additions on the extraction of grapeseed oil

[0072] (1) Grape seed pretreatment: The grape seeds are pulverized by a universal mill and passed through a 50-mesh sieve to obtain the raw material of grape seed powder. %, and the fiber content is 30.6%.

[0073] (2) Mixed enzyme enzymolysis: Mix distilled water and grape seed powder in a volume-to-mass ratio of 5 (mL): 1 (g) to obtain a slurry, add hydrochloric acid to adjust the pH of the slurry to 5, and add 1% mixed enzyme ( The ratio of cellulase: pectinase: hemicellulase: xylanase is 0.6:0.1:0.2:0.1), the enzymatic hydrolysis reaction temperature is 50°C, and the enzymatic hydrolysis reaction time is 2h;

[0074] (3) Protease hydrolysis: add protease for enzymolysis, the enzymolysis reaction temperature is 50°C, the enzymolysis reaction time is 2h, and the amount of protease added and pH are shown in Table 2.

[0075] (4) lye extraction: sodium hydroxide and distilled water ...

Embodiment 3

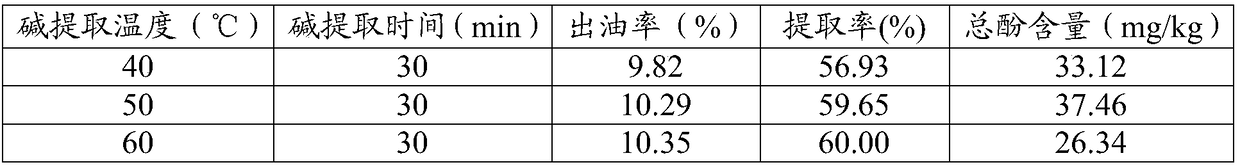

[0080] Example 3 Effects of acid protease hydrolysis temperature, time and pH on extraction of grapeseed oil

[0081] (1) Grape seed pretreatment: The grape seeds are pulverized by a universal mill and passed through a 50-mesh sieve to obtain the raw material of grape seed powder. %, and the fiber content is 30.6%.

[0082] (2) Mixed enzyme enzymolysis: Mix distilled water and grape seed powder in a volume-to-mass ratio of 5 (mL): 1 (g) to obtain a slurry, add hydrochloric acid to adjust the pH of the slurry to 5, and add 1% mixed enzyme ( The ratio of cellulase: pectinase: hemicellulase: xylanase is 0.6:0.1:0.2:0.1), the enzymatic hydrolysis reaction temperature is 50°C, and the enzymatic hydrolysis reaction time is 2 h.

[0083] (3) Enzymatic hydrolysis with acid protease: add hydrochloric acid to the slurry, and add acid protease for enzymatic hydrolysis, and the addition amount is 1%. The enzymatic hydrolysis temperature, enzymatic hydrolysis time and pH of acidic proteas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com