Paint remover capable of being used circularly

A technology of paint remover and penetrating agent, which is applied in the field of recyclable paint remover, can solve the problems of low recycling rate of waste water, impact on health, corrosion of metal workpieces, etc., achieve high recycling rate, wide application range, universal strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

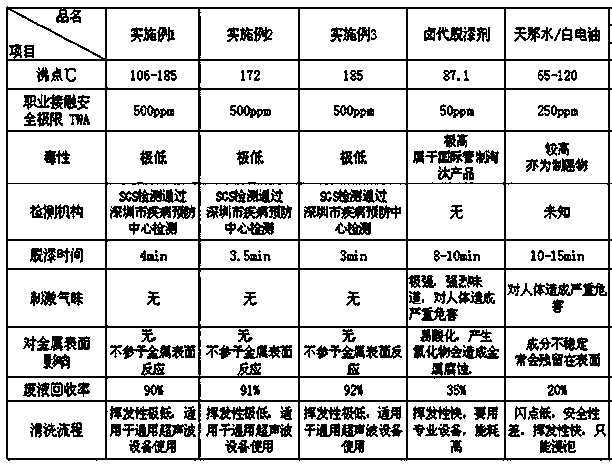

Examples

Embodiment 1

[0020] A recyclable paint remover is made from the following components by weight:

[0021] D40 solvent oil 27%,

[0022] Ethylene glycol ether 13%,

[0023] Dipropylene glycol butyl ether 18%,

[0024] Butyl acetate 12%,

[0025] Alcohol solvent 11%,

[0026] Ketone solvent 13%,

[0027] Penetrant 6%.

[0028] In one embodiment, the alcoholic solvent is ethanol.

[0029] In one embodiment, the ketone solvent is acetone.

[0030] In one embodiment, the penetrating agent is a fast penetrating agent T.

Embodiment 2

[0032] A recyclable paint remover is made from the following components by weight:

[0033] D40 solvent oil 23%,

[0034] Ethylene glycol ether 15%,

[0035] Dipropylene glycol butyl ether 16%,

[0036] Butyl acetate 11%,

[0037] Alcohol solvent 12%,

[0038] Ketone solvent 15%,

[0039] Penetrant 8%.

[0040] In one embodiment, the alcoholic solvent is isopropanol.

[0041] In one embodiment, the ketone solvent is cyclohexanone.

[0042] In one embodiment, the penetrant is penetrant JFC-C.

Embodiment 3

[0044] A recyclable paint remover is made from the following components by weight:

[0045] D40 solvent oil 34%,

[0046] Ethylene glycol ether 12%,

[0047] Dipropylene glycol butyl ether 11%,

[0048] Butyl acetate 13%,

[0049] Alcohol solvent 11%,

[0050] Ketone solvent 12%,

[0051] Penetrant 7%.

[0052] In one embodiment, the alcohol solvent is a mixture of 5% by weight ethanol and 6% by weight isopropanol.

[0053] In one embodiment, the ketone solvent is a mixture of 6% by weight acetone and 6% by weight cyclohexanone.

[0054] In one embodiment, the penetrant is a mixture of 3% by weight of fast penetrant T and 4% by weight of penetrant JFC-C.

[0055] The present invention also provides a manufacturing process for making a solution from a recyclable paint remover. Step 1. Put the penetrating agent and the alcohol solvent in the above weight ratio into the measuring bucket at the same time, and then add the penetrating agent into the measuring bucket. The ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com