Fluoropolymer/nano SiO2 superhydrophobic coating layer and preparation method thereof

A super-hydrophobic coating and super-hydrophobic coating technology, which is applied in the coating, anti-corrosion coating, etc., can solve the problems of complicated process, short service life, and decreased hydrophobic performance, and achieve simple preparation methods, broad application prospects, and enhanced mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] In one embodiment of the present invention, a kind of fluorine-containing copolymer / nanometer SiO is provided 2 The preparation method of superhydrophobic coating, comprises the steps:

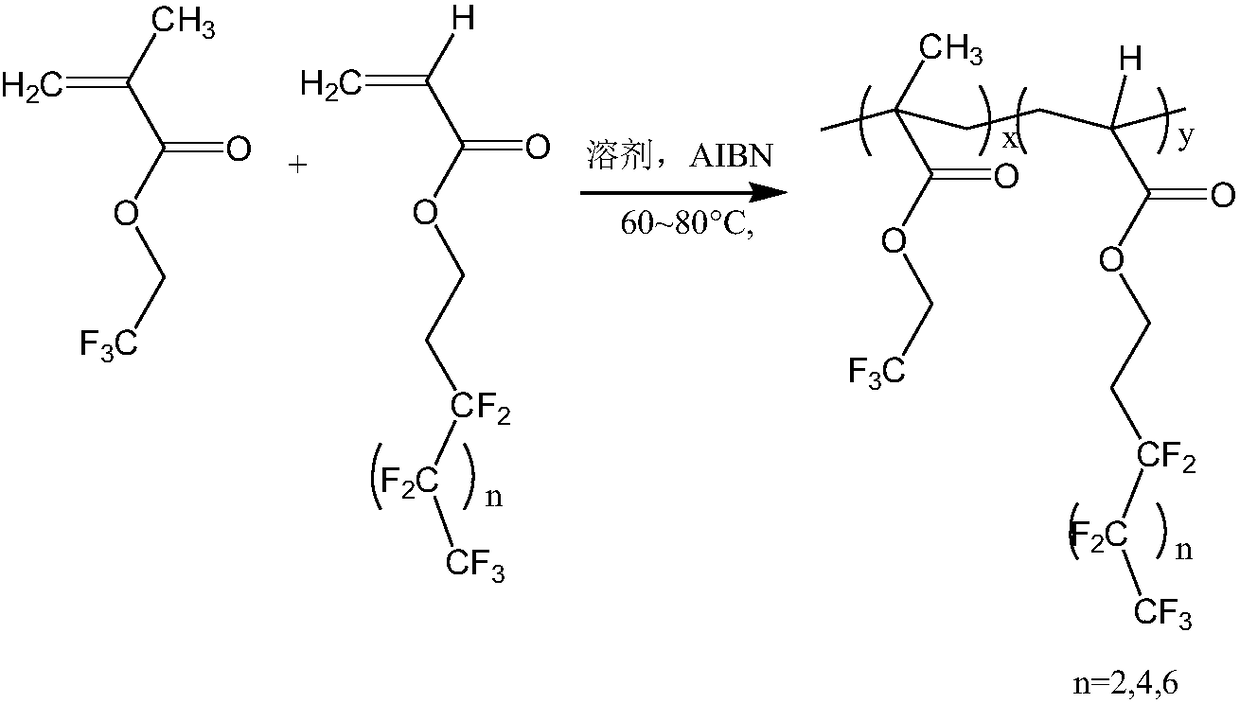

[0034] (1) Add trifluoroethyl methacrylate (TFEMA) and perfluoroalkyl ethyl acrylate to the reaction solvent in a molar ratio of 1:0.01 to 1:100; use azobisisobutyronitrile (AIBN) as The initiator carries out free radical solution polymerization, and the temperature of free radical solution polymerization is between 60 and 80°C; the reaction time is 12 to 48 hours; the polymer produced by the reaction is repeatedly dissolved and precipitated three times; dried at 100°C for 48 hours or more Obtain the binary random fluorine-containing copolymer of TFEMA and TEAc-8;

[0035] (2) Dissolving the resulting fluorine-containing copolymer in a solvent to form a polymer solution, adding hydrophobic nano-SiO 2 , so that nano-SiO 2The content of the superhydrophobic composite coating is 1-10wt%...

Embodiment 1

[0046] Add 3g of TFEMA, 3g of perfluorobutyl ethyl acrylate, 20ml of N,N-dimethylformamide and 0.05g of AIBN into a 100ml single-necked bottle, vacuumize and protect with nitrogen. After 30 minutes of magnetic stirring at room temperature, the temperature was raised to 60° C., and the reaction was stopped after 48 hours. The reacted solution was added dropwise to 500ml of distilled water, and after standing for 20 minutes, the precipitate was filtered out, and dried at 100°C. The obtained crude product was repeatedly dissolved and precipitated three times with tetrahydrofuran and methanol, and dried at 100° C. for 48 hours to obtain the final product—a fluorine-containing copolymer.

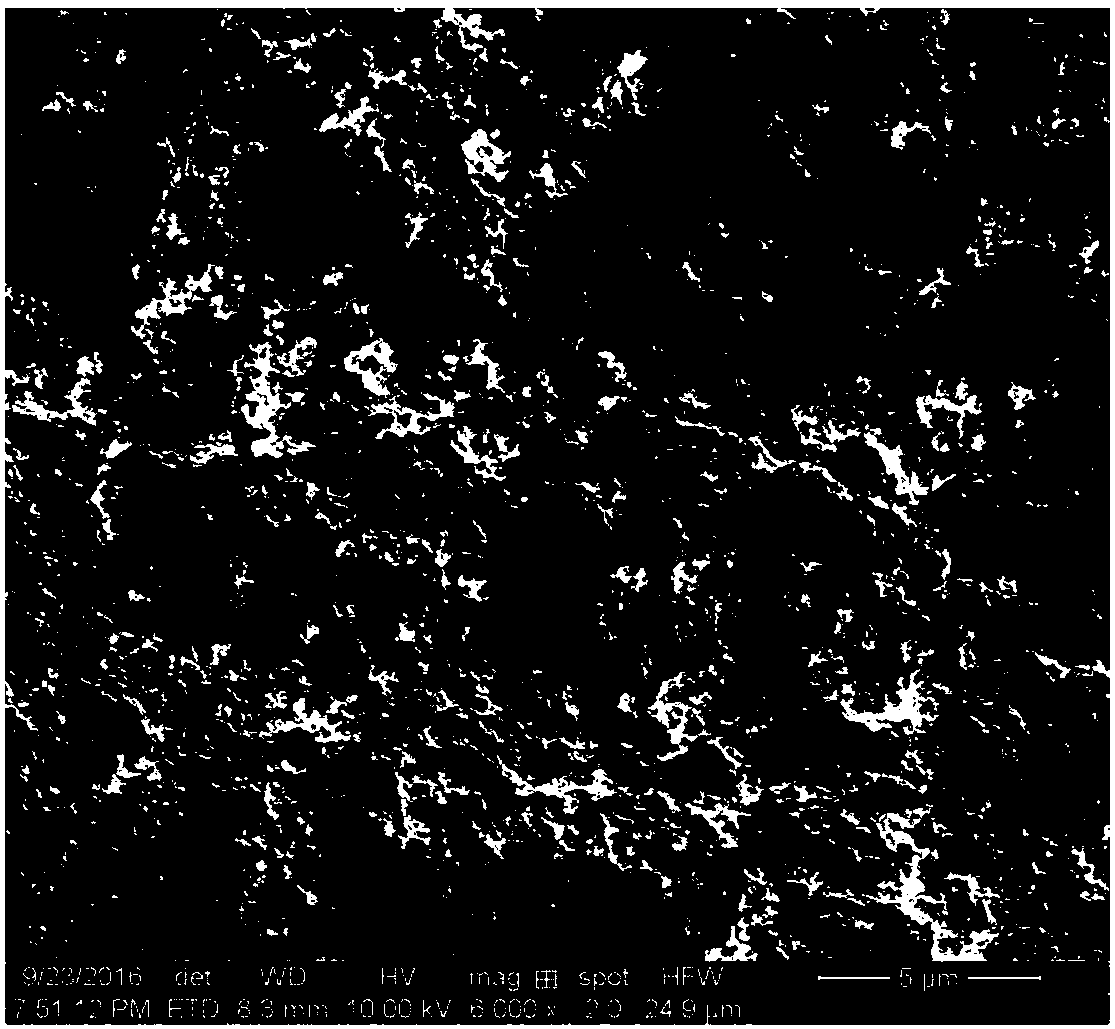

[0047] 0.01g fluorine-containing copolymer and 0.01g nano-SiO 2 Dissolved in 1ml N,N-dimethylformamide, ultrasonicated for 30 minutes to obtain fluorine-containing copolymer / nano-SiO 2 Superhydrophobic coatings. Take 100 μl of the superhydrophobic coating and spin-coat it on a glass slide to f...

Embodiment 2

[0050] Add 3g of TFEMA, 6g of perfluorooctyl ethyl acrylate, 25ml of N,N-dimethylformamide and 0.1g of AIBN into a 100ml single-necked bottle, vacuumize and protect with nitrogen. After 30 minutes of magnetic stirring at room temperature, the temperature was raised to 80° C., and the reaction was stopped after 24 hours. The reacted solution was added dropwise to 500ml of distilled water, and after standing for 20 minutes, the precipitate was filtered out, and dried at 100°C. The obtained crude product was repeatedly dissolved and precipitated three times with tetrahydrofuran and methanol, and dried at 100° C. for 48 hours to obtain the final product—a fluorine-containing copolymer.

[0051] 0.01g fluorine-containing copolymer and 0.01g nano-SiO 2 Dissolved in 1ml N,N-dimethylacetamide, ultrasonic treatment for 30 minutes to obtain fluorine-containing copolymer / nano-SiO 2 Superhydrophobic coatings. Take 60 μl of the superhydrophobic coating and spin-coat it on a glass slide ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com