Preserved beancurd maturing fermentation composite bacterial agent and preparation method thereof

A technology for fermenting compound bacteria and fermented bean curd, applied in biochemical equipment and methods, dairy products, streptococcus/lactococcus, etc., can solve the problems of unclear interaction mechanism of flavor microorganisms, low level of product quality control, large area of factory buildings, etc. problem, achieve the effect of improving the flavor and amino acid nitrogen content, shortening the time required for production, and increasing the fermentation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

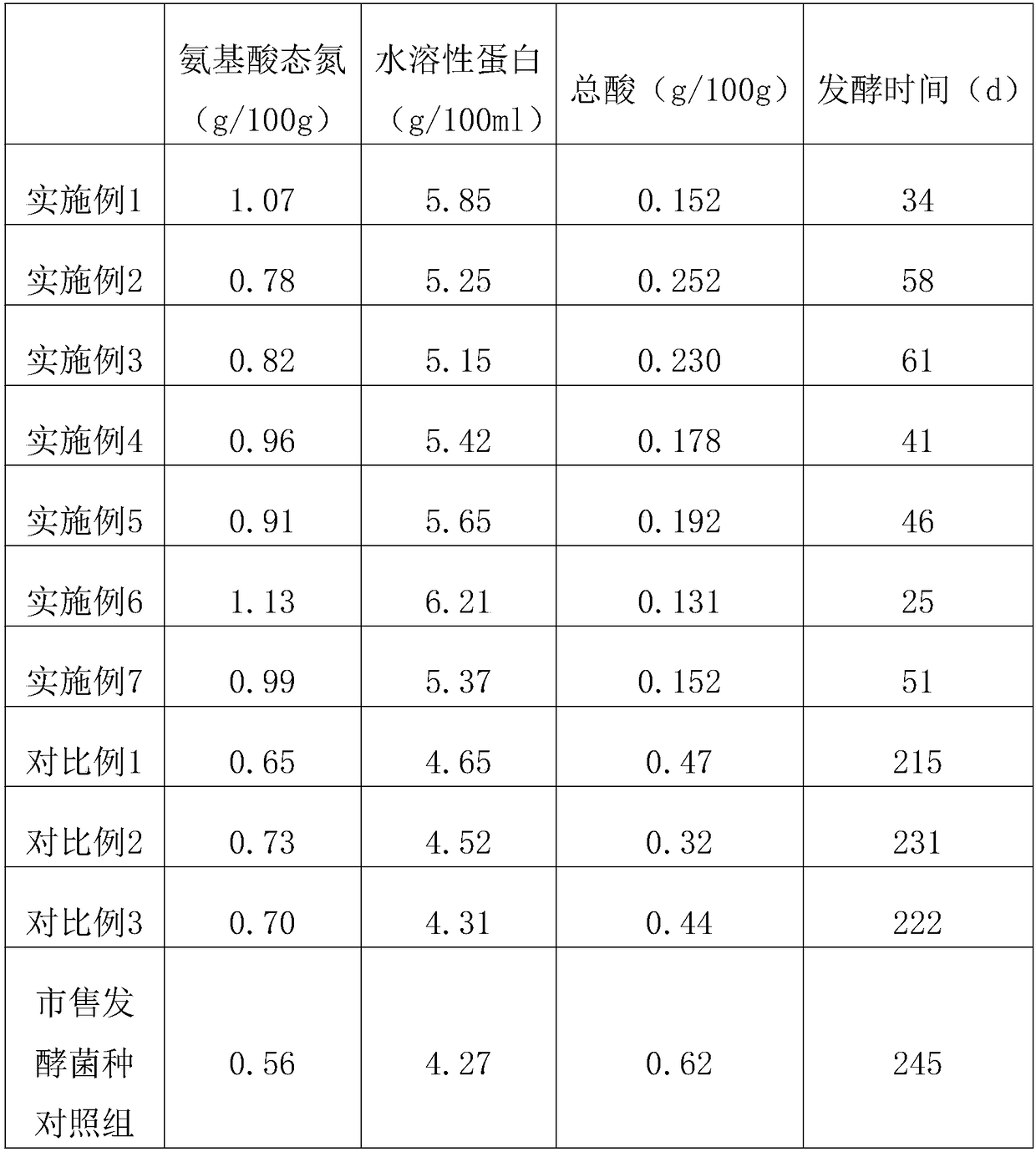

Examples

Embodiment 1

[0030] A fermented fermented bean curd ripening-promoting fermentation compound microbial agent, prepared by the following method:

[0031] (1) Strain activation

[0032]According to the physiological and biochemical characteristics of the target strain, nutrient agar medium, Bengal red medium and PDA agar medium were used to spread the plate respectively, and placed in a constant temperature biochemical incubator to activate for two generations before use. Kodak yeast was inoculated on 5°Bé malt juice agar medium, cultured at 27°C-29°C for 52 hours, Lactococcus lactis subsp. lactis was inoculated on lactic acid bacteria medium, and cultivated at 36°C-38°C for 30 hours;

[0033] (2) Multiplication and cultivation

[0034] The strains activated in step (1) were respectively inoculated on the matrix carrier medium for propagation and cultivation, wherein fermenting Pichia pastoris and Omerkoda yeast were inoculated on the wheat flour matrix carrier medium, and Lactococcus lacti...

Embodiment 2

[0042] A fermented fermented bean curd ripening-promoting fermentation compound microbial agent, prepared by the following method:

[0043] (1) Strain activation

[0044] According to the physiological and biochemical characteristics of the target strain, nutrient agar medium, red Bengal medium and PDA agar medium were used to streak the plate, and placed in a constant temperature biochemical incubator to activate for two generations before standby, in which Pichia pastoris and Omer Kodak yeast was inoculated in 5°Bé malt juice agar medium, cultured at 27°C-29°C for 48 hours, Lactococcus lactis subsp. lactis was inoculated in lactic acid bacteria medium, and cultivated at 36°C-38°C for 24 hours;

[0045] (2) Multiplication and cultivation

[0046] The strains activated in step (1) were respectively inoculated on the matrix carrier medium for propagation and cultivation, wherein fermenting Pichia pastoris and Omerkoda yeast were inoculated on the wheat flour matrix carrier med...

Embodiment 3

[0054] A fermented fermented bean curd ripening-promoting fermentation compound microbial agent, prepared by the following method:

[0055] (1) Strain activation

[0056] According to the physiological and biochemical characteristics of the target strain, nutrient agar medium, Bengal red medium and PDA agar medium were used to spread the plate respectively, and placed in a constant temperature biochemical incubator to activate for two generations before use. Kodak yeast was inoculated in 5°Bé malt juice agar medium, cultured at 27°C-29°C for 56 hours, Lactococcus lactis subspecies lactis was inoculated in lactic acid bacteria medium, and cultivated at 36°C-38°C for 36 hours;

[0057] (2) Multiplication and cultivation

[0058] The strains activated in step (1) were respectively inoculated on the matrix carrier medium for propagation and cultivation, wherein fermenting Pichia pastoris and Omerkoda yeast were inoculated on the wheat flour matrix carrier medium, and Lactococcus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com