Lithium negative electrode preform, preparation method thereof, lithium negative electrode, and lithium secondary battery

A technology of lithium metal negative electrode and prefabricated parts, which is applied in the protection of lithium metal negative electrode and the field of lithium metal secondary batteries, and can solve the problems of unstable SEI film, reduced Coulombic efficiency, uneven distribution of current density, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

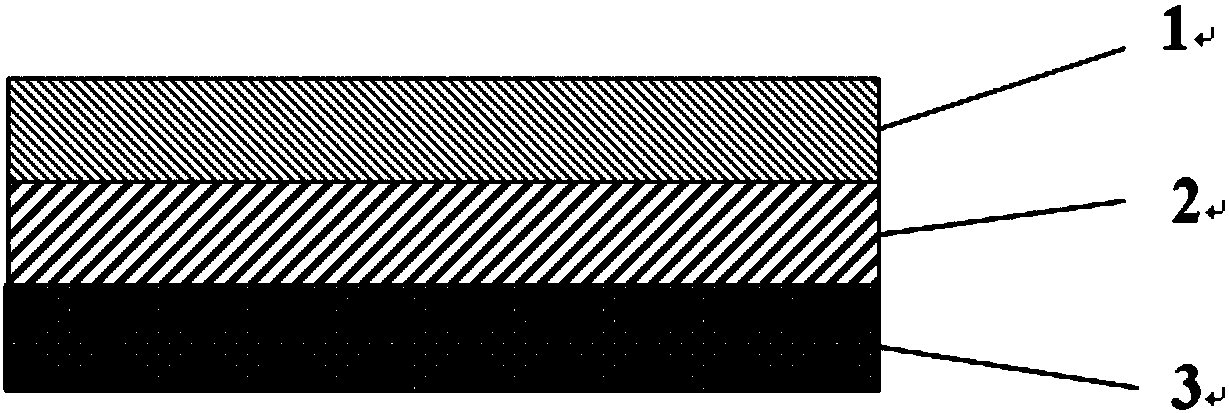

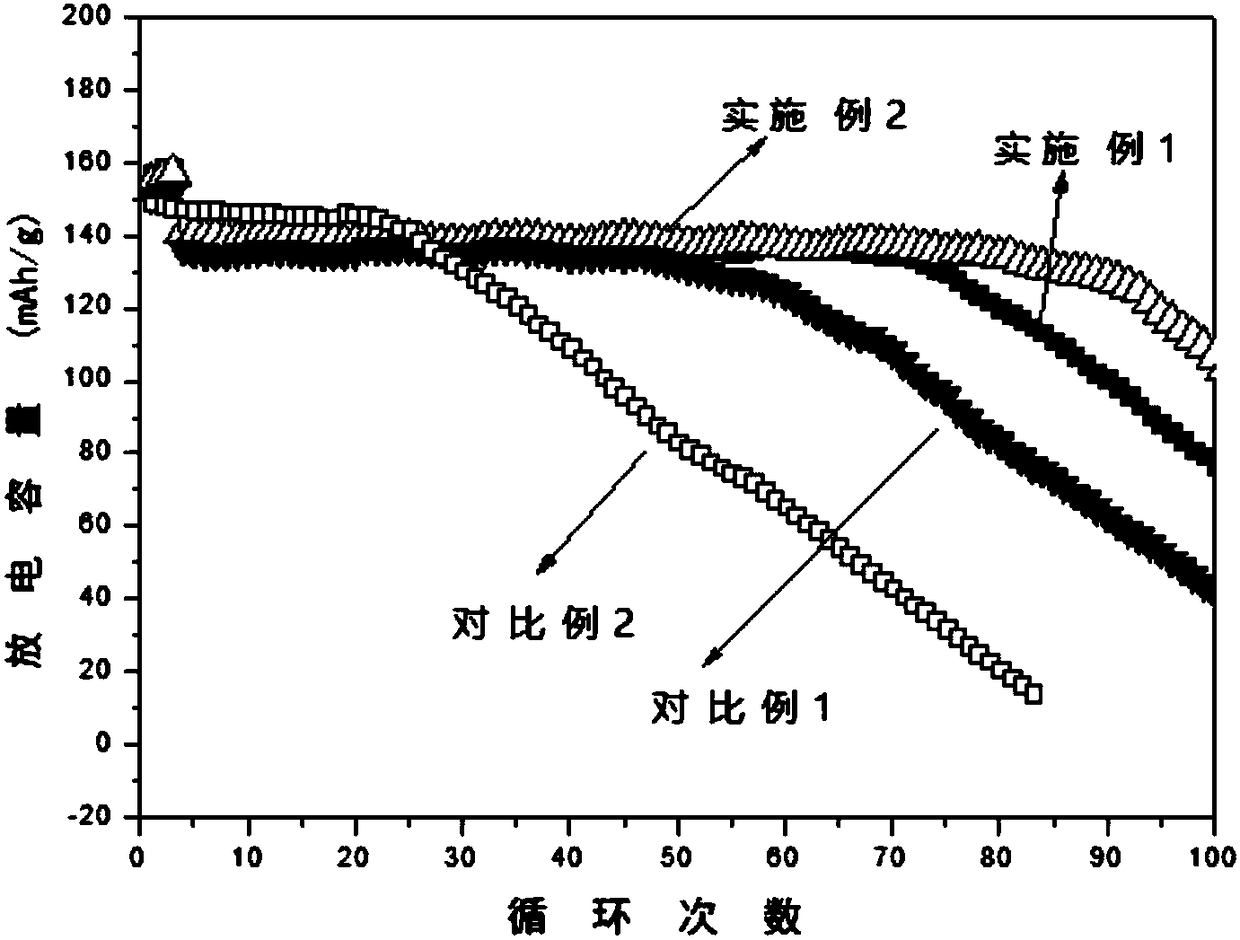

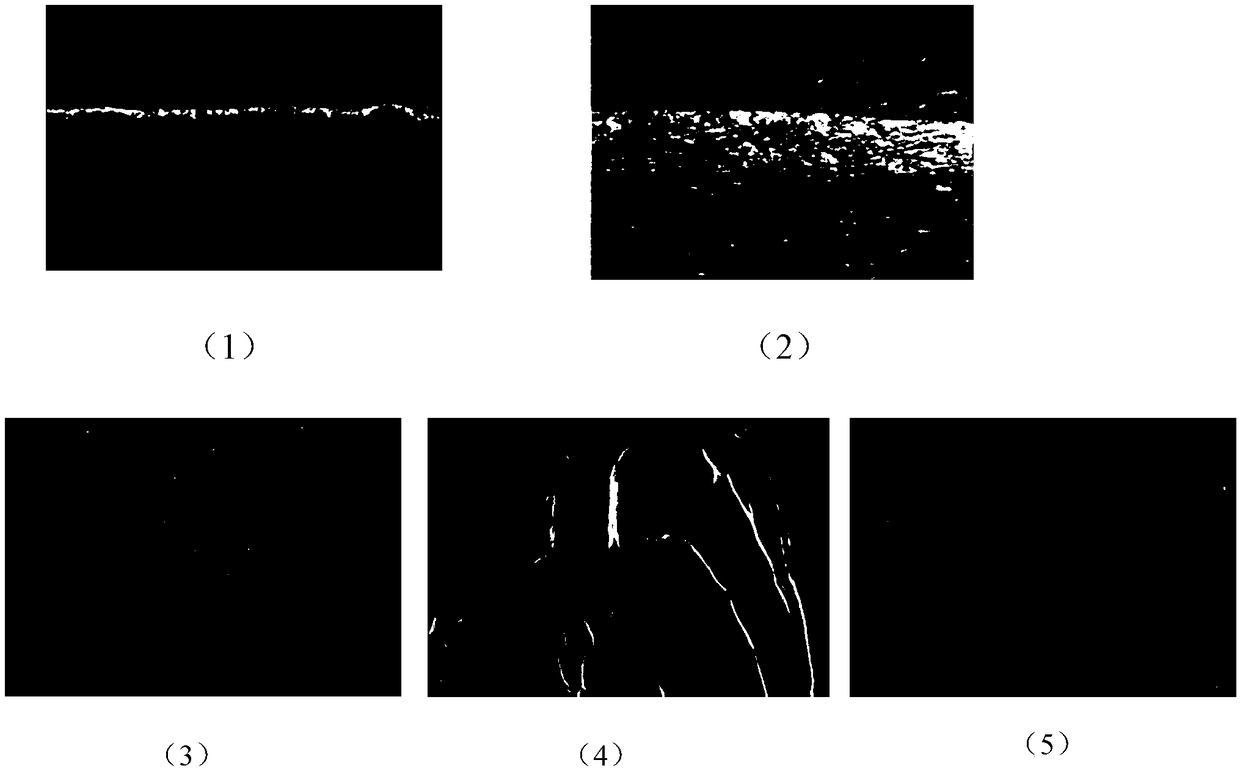

[0034] Example 1: Choose PET with a thickness of 5 μm as the plastic substrate, mix polyvinylidene fluoride, lithium trifluoromethanesulfonate, and titanium dioxide in a mass ratio of 100:40:20, and heat it to a molten state. Extruded onto a PET substrate, the thickness is controlled to be 5 μm, and after cooling, it is combined with a lithium strip with a thickness of 40 μm in a dry environment at 25 ° C, and the pressure is 10 MPa. After pressing, a lithium metal with a protective layer is formed. Negative electrode, and then put this negative electrode on the heating plate, set the heating temperature to 80 ° C, remove the plastic substrate, and at the same time, the solid electrolyte and the lithium metal negative electrode can also contact more closely under high temperature conditions, and form a protective film in situ; then A lithium metal negative electrode with a solid electrolyte and a lithium iron phosphate positive electrode constitute a laminated all-solid-state b...

Embodiment 2

[0035] Example 2: Select polyvinyl fluoride (PVF) with a thickness of 10 μm as the plastic substrate, and dissolve polyacrylonitrile, lithium acetate, aluminum oxide, and styrene-butadiene rubber in isopropanol according to the ratio of mass 100:45:25:10 Stir to form an emulsion with a solid content of 50%, and then spray the emulsion on the plastic substrate with a spraying equipment to control the thickness of 3 μm, and dry it at a temperature of 90°C for 55 minutes. The dried double layer The composite film and the lithium strip with a thickness of 25 μm are cold-pressed and composited at 30 ° C, and the pressure is 15 MPa. After pressing, a lithium metal negative electrode with a protective layer is formed, and then the negative electrode is placed on a heating plate, and the heating temperature is set to 90 ℃, remove the plastic substrate, and at the same time, the solid electrolyte and the lithium metal negative electrode can also contact more closely under high temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com