A kind of sialon bonded fused silica preform for aluminum water flow tank and its manufacturing method

A technology of fused silica and manufacturing method, which is applied in the field of sialon combined fused silica preforms for aluminum water flow tanks and its manufacturing field, which can solve the problems of poor density and volume stability, impossibility of practical application of aluminum water flow tanks, increased chances of chemical attack, etc. Problems, achieve excellent volume stability and thermal shock resistance, excellent volume stability and thermal shock resistance, and improve the effect of aluminum water erosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

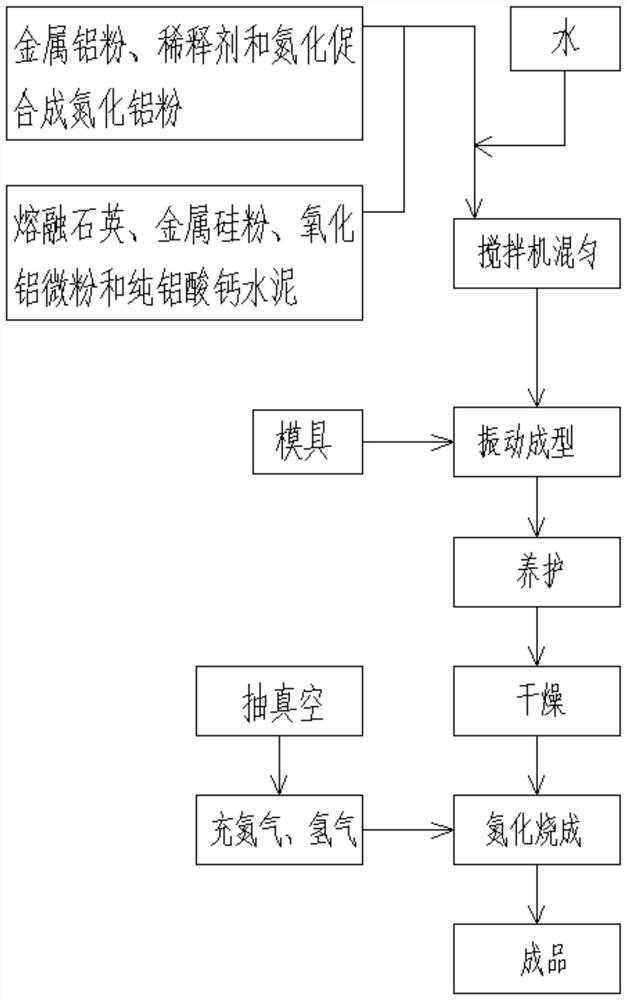

[0030] A method for producing a molten melted stone prefabricated by an aluminum water tank, which is as follows:

[0031] (1) Synthesis of aluminum nitride powder: metal aluminum powder, diluent and nitriding promoter NH 4 Cl Add to the vacuum nitride by reaction (1) Al (s) + N 2 (G) === AlN (g), aluminum nitride powder obtained by reacting, to remove impurities to give the aluminum nitride powder of high purity, the diluent particle size of 3μm Al 2 O 3 Micro powder, metal aluminum powder, diluent and nitriding promoter NH 4 Cl weight ratio of 1: 1: 0.3;

[0032] (2) A fused silica, silicon metal powder, the step (1) made of aluminum nitride powder, aluminum powder and calcium aluminate cement mixer dry blended uniformly mixed to obtain a dry material 15min, 10min stirring mixture was added water to obtain a slurry;

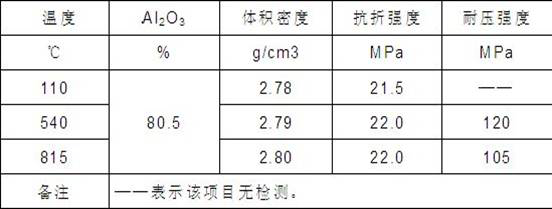

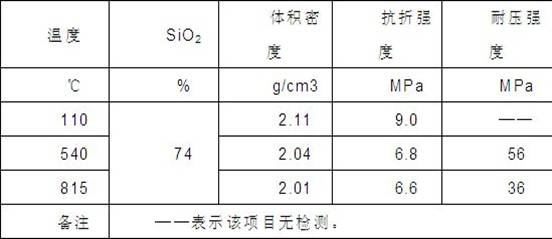

[0033] Percentage by weight, the fused silica by more than 5 ~ 3mm99.6wt% quartz particles 8%, more than 3 ~ 1mm99.6wt% silica particles 25%, more than 1 ~ 0.5mm99...

Embodiment 2

[0039] A method for producing a molten melted stone prefabricated by an aluminum water tank, which is as follows:

[0040] (1) Synthesis of aluminum nitride powder: metal aluminum powder, diluent and nitriding promoter NH 4 Cl Add to the vacuum nitride by reaction (1) Al (s) + N 2 (G) === AlN (g), aluminum nitride powder obtained by reacting, to remove impurities to give the aluminum nitride powder of high purity, the diluent particle size of 3μm Al 2 O 3 Micro powder, metal aluminum powder, diluent and nitriding promoter NH 4 Cl weight ratio of 1: 1: 0.3;

[0041] (2) After the fused silica, silicon metal powder, the step (1) made of aluminum nitride powder, aluminum powder and calcium aluminate cement mixer to obtain dry blended dry feed mix 15min, 12min stirring water was added and mixed to give slurry;

[0042] Percentage by weight, the fused silica by more than 5 ~ 3mm99.6wt% silica particles 10% or more, 3 ~ 1mm99.6wt% silica particles 30%, more than 1 ~ 0.5mm99.6wt% 10% mel...

Embodiment 3

[0047] A method for producing a molten melted stone prefabricated by an aluminum water tank, which is as follows:

[0048] (1) Synthesis of aluminum nitride powder: metal aluminum powder, diluent and nitriding promoter NH 4 Cl Add to the vacuum nitride by reaction (1) Al (s) + N 2 (G) === AlN (g), aluminum nitride powder obtained by reacting, to remove impurities to give the aluminum nitride powder of high purity, the diluent particle size of 3μm Al 2 O 3 Micro powder, metal aluminum powder, diluent and nitriding promoter NH 4 Cl weight ratio of 1: 1: 0.3;

[0049] (2) After the fused silica, silicon metal powder, the step (1) made of aluminum nitride powder, aluminum powder and calcium aluminate cement mixer to obtain dry blended dry feed mix 15min, 15min stirring water was added and mixed to give slurry;

[0050] Percentage by weight, the fused silica by more than 5 ~ 3mm99.6wt% silica particles 5% or more, 3 ~ 1mm99.6wt% silica particles 35%, more than 1 ~ 0.5mm99.6wt% 8% melt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com